When it comes to exterior cladding options, homeowners and builders often find themselves weighing the costs and benefits of waterproof panels against traditional siding. While waterproof exterior wall panels may have a higher initial cost, they often prove more cost-effective in the long run. These panels offer superior durability, energy efficiency, and lower maintenance requirements, potentially saving money over time. Traditional siding, while generally less expensive upfront, may require more frequent repairs and replacements. Ultimately, the cost comparison depends on factors such as climate, building type, and long-term maintenance considerations, making it essential to evaluate both options carefully for your specific project needs.

Understanding Waterproof Exterior Wall Panels

What are Waterproof Exterior Wall Panels?

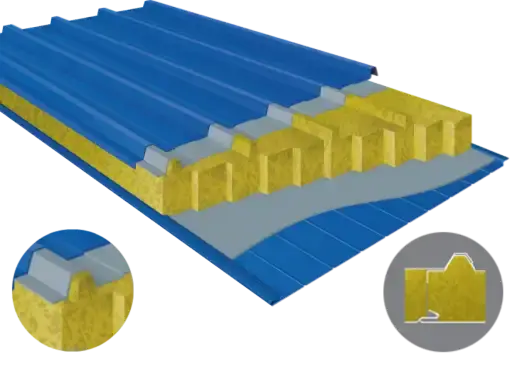

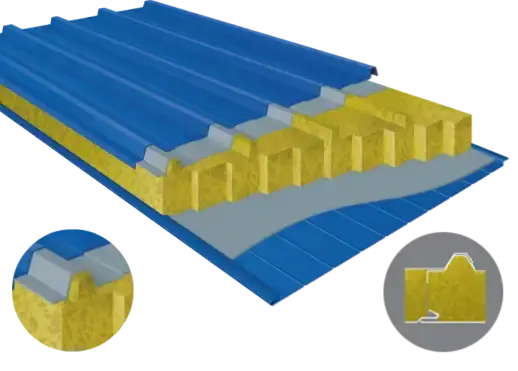

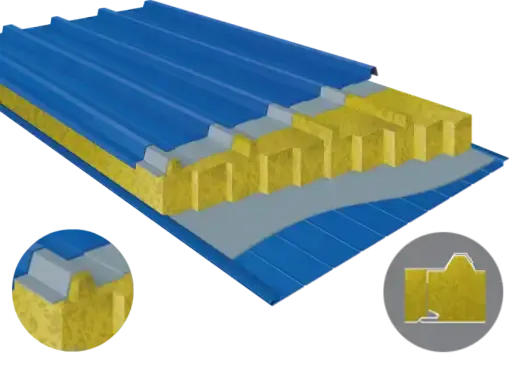

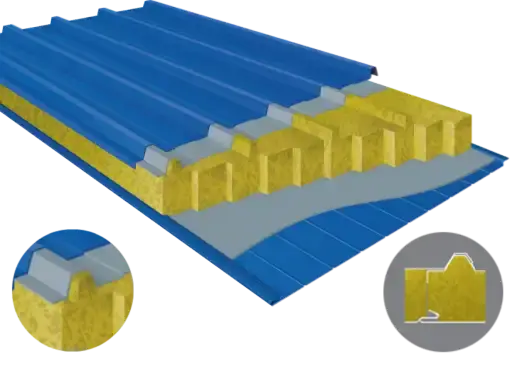

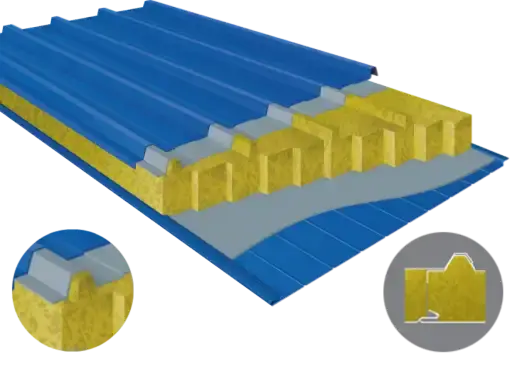

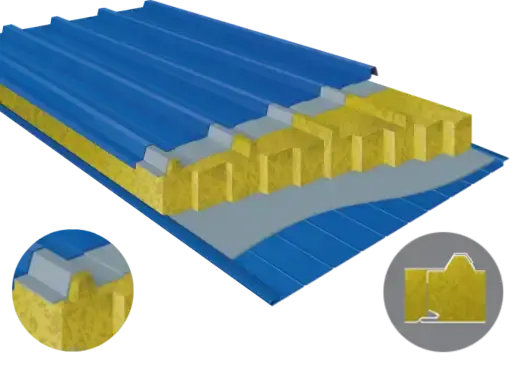

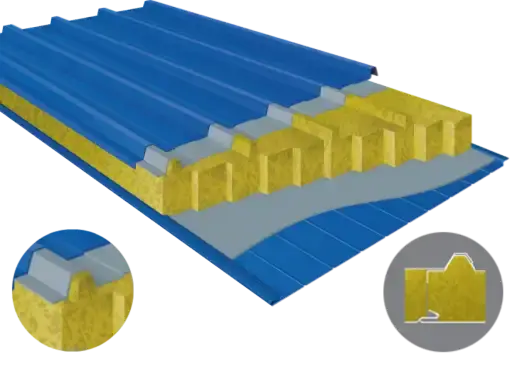

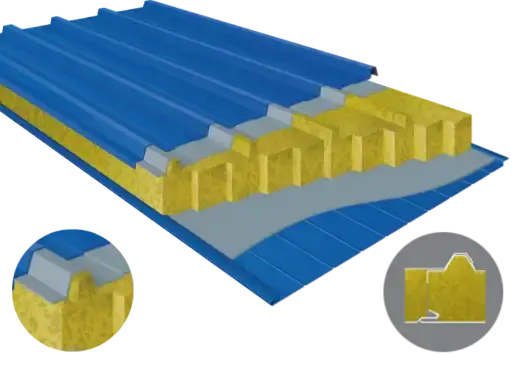

Waterproof exterior wall panels are innovative building materials designed to protect structures from moisture infiltration while enhancing their aesthetic appeal. These panels are engineered to withstand various weather conditions, including heavy rain, snow, and high humidity. Unlike traditional siding options, waterproof exterior wall panels create a seamless barrier against water, preventing potential damage to the building's interior and structural components.

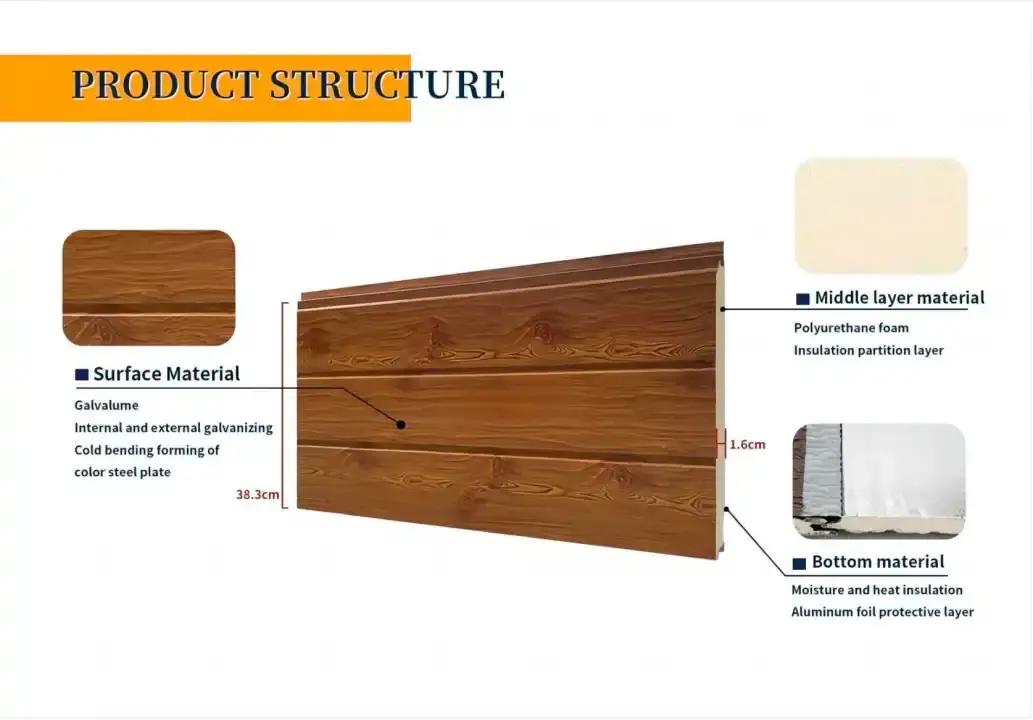

Typically, these panels are constructed using advanced materials such as fiber cement, metal, or composite materials. The waterproof exterior wall panels factory employs cutting-edge technology to ensure each panel meets rigorous quality standards. For instance, Weifang Sandong Building Materials Co., Ltd. is equipped with state-of-the-art production lines and quality control systems, meticulously testing every aspect of their panels, from steel coils and aluminum foil to polyurethane components.

Benefits of Waterproof Exterior Wall Panels

The advantages of choosing waterproof exterior wall panels extend far beyond their primary function of moisture protection. These panels offer a myriad of benefits that contribute to their growing popularity in the construction industry:

- Superior Durability: Waterproof panels are engineered to withstand harsh environmental conditions, resisting damage from UV rays, extreme temperatures, and physical impacts.

- Energy Efficiency: Many waterproof panels incorporate insulation properties, helping to regulate indoor temperatures and reduce energy consumption.

- Low Maintenance: These panels require minimal upkeep, saving time and money on regular maintenance tasks associated with traditional siding.

- Versatility: Waterproof exterior wall panels are available in a wide range of colors, textures, and styles, allowing for creative architectural designs.

- Fire Resistance: Many waterproof panels are manufactured with fire-resistant materials, enhancing building safety.

- Noise Reduction: The dense composition of these panels can help in reducing external noise, creating a more peaceful indoor environment.

Applications of Waterproof Exterior Wall Panels

The versatility of waterproof exterior wall panels makes them suitable for a wide range of construction projects. Architects and builders choose these panels for their superior performance and aesthetic appeal in various applications:

- Residential Complexes: Multi-family housing units benefit from the durability and low maintenance requirements of waterproof panels.

- Office Buildings: Commercial structures utilize these panels to create modern, energy-efficient facades that impress clients and employees alike.

- Villas and Luxury Homes: High-end residential properties leverage the aesthetic versatility of waterproof panels to achieve unique architectural designs.

- Garden Structures: Outdoor living spaces and garden buildings gain protection and style from waterproof exterior wall panels.

- Historic Building Renovations: These panels can be used to restore and protect heritage buildings while maintaining their character.

- Municipal Buildings: Government facilities benefit from the longevity and low maintenance costs associated with waterproof panels.

- Security Kiosks: Small, standalone structures utilize these panels for their durability and weather resistance.

Cost Comparison: Waterproof Panels vs. Traditional Siding

Initial Installation Costs

When comparing the upfront costs of waterproof exterior wall panels to traditional siding options, it's important to consider several factors:

- Material Costs: Waterproof panels typically have a higher per-unit cost than traditional siding materials like vinyl or wood. The advanced manufacturing processes and high-quality materials used in waterproof exterior wall panels contribute to their higher price point.

- Installation Complexity: The installation of waterproof panels may require specialized skills and tools, potentially increasing labor costs. However, some waterproof panel systems are designed for easier installation, which can partially offset this difference.

- Preparation Requirements: Traditional siding often necessitates more extensive preparation of the underlying structure, including the installation of a moisture barrier. Waterproof panels may reduce or eliminate some of these preparatory steps, potentially saving on installation time and materials.

- Quantity Needed: Due to their larger size and coverage area, fewer waterproof panels may be required to cover the same surface area as traditional siding, which could impact the overall material cost.

Long-Term Maintenance and Replacement Costs

The true cost comparison between waterproof panels and traditional siding becomes more apparent when considering long-term maintenance and replacement expenses:

- Durability: Waterproof exterior wall panels are engineered for longevity, often lasting decades with minimal degradation. Traditional siding materials may require replacement or significant repairs much sooner, especially in harsh climates.

- Maintenance Requirements: Traditional siding often needs regular painting, sealing, or staining to maintain its appearance and protective qualities. Waterproof panels typically require only occasional cleaning to keep them looking new, significantly reducing ongoing maintenance costs.

- Repair Frequency: The robust nature of waterproof panels makes them less susceptible to damage from impacts, weather, or pests. Traditional siding may need more frequent repairs due to warping, cracking, or insect infestation.

- Energy Savings: Many waterproof exterior wall panels offer superior insulation properties, potentially leading to lower heating and cooling costs over time. This energy efficiency can result in substantial savings, especially for larger buildings.

- Property Value: The modern appearance and high-performance characteristics of waterproof panels can enhance a property's value, potentially offering a better return on investment compared to traditional siding options.

Factors Influencing Cost-Effectiveness

Several factors can influence the cost-effectiveness of choosing waterproof exterior wall panels over traditional siding:

- Climate Considerations: In areas with extreme weather conditions, such as high humidity, frequent storms, or severe temperature fluctuations, the durability of waterproof panels can provide significant long-term savings.

- Building Type and Usage: Commercial buildings or high-end residential properties may benefit more from the aesthetic and performance advantages of waterproof panels, justifying the higher initial investment.

- Local Labor Costs: The complexity of installation can impact overall costs differently depending on local labor rates and the availability of skilled installers.

- Energy Efficiency Regulations: In regions with strict energy codes, the insulation properties of waterproof panels may help meet requirements more easily than traditional siding options.

- Maintenance Capabilities: For property owners without the time or resources for regular maintenance, the low-maintenance nature of waterproof panels can be particularly cost-effective.

- Lifecycle Expectations: Buildings intended for long-term use or those in the public sector may find greater value in the extended lifespan of waterproof exterior wall panels.

Understanding these factors can help property owners and builders make informed decisions about whether the investment in waterproof exterior wall panels aligns with their specific needs and long-term financial goals.

Making an Informed Decision

Assessing Your Specific Needs

When deciding between waterproof exterior wall panels and traditional siding, it's crucial to evaluate your unique circumstances:

- Project Goals: Determine whether your primary objectives are long-term durability, aesthetic appeal, energy efficiency, or minimal maintenance.

- Budget Constraints: Consider both your immediate budget for installation and your capacity for long-term maintenance and potential replacements.

- Environmental Factors: Assess local climate conditions, including humidity levels, precipitation frequency, and temperature extremes.

- Building Design: Evaluate how different cladding options complement your building's architectural style and structural requirements.

- Regulatory Compliance: Research local building codes and energy efficiency standards that may influence your choice of exterior cladding.

- Lifecycle Expectations: Consider how long you intend to own or occupy the building, as this can impact the value of investing in more durable materials.

Consulting with Professionals

Making an informed decision often requires expert input. Consider consulting with the following professionals:

- Architects: Can provide insights on how different cladding options align with your design goals and building requirements.

- Contractors: Offer practical knowledge about installation processes, local availability of materials, and potential challenges.

- Energy Efficiency Consultants: Can help calculate potential energy savings from different cladding options.

- Building Envelope Specialists: Provide expertise on moisture management and the long-term performance of various cladding systems.

- Manufacturers: Companies like Weifang Sandong Building Materials Co., Ltd. can offer detailed information about their waterproof exterior wall panels, including performance data and cost projections.

Evaluating Total Cost of Ownership

To make a comprehensive cost comparison, consider the total cost of ownership over the expected life of your building:

- Initial Costs: Include materials, labor, and any necessary preparatory work for both waterproof panels and traditional siding options.

- Maintenance Expenses: Calculate the projected costs of regular upkeep, including cleaning, painting, and repairs over time.

- Energy Savings: Estimate potential reductions in heating and cooling costs due to improved insulation properties.

- Replacement Cycles: Consider how often each option might need to be replaced and factor in those future costs.

- Insurance Implications: Some insurance providers offer discounts for buildings with high-performance cladding systems.

- Resale Value: Assess how each option might impact the future market value of your property.

Conclusion

In conclusion, the cost comparison between waterproof exterior wall panels and traditional siding reveals a complex interplay of factors. While waterproof panels generally have a higher initial cost, their superior durability, energy efficiency, and low maintenance requirements often result in lower long-term expenses. The decision ultimately depends on your specific project needs, climate conditions, and long-term goals. By carefully evaluating these factors and consulting with professionals, you can make an informed choice that balances upfront costs with long-term value. Waterproof exterior wall panels offer a compelling solution for those seeking a durable, efficient, and aesthetically pleasing building envelope.

If you're considering waterproof exterior wall panels for your next construction project, we invite you to explore the high-quality options offered by Weifang Sandong Building Materials Co., Ltd. Our expert team is ready to assist you in finding the perfect exterior cladding solution that meets your performance and budget requirements. For more information or to discuss your specific needs, please contact us at info@sdqsc.com.

FAQ

Are waterproof exterior wall panels suitable for all climate types?

Yes, waterproof exterior wall panels are designed to perform well in various climates, from hot and humid to cold and wet environments. However, specific panel types may be better suited for certain climates, so it's important to consult with experts or manufacturers like Weifang Sandong Building Materials Co., Ltd. to choose the most appropriate option for your location.

How long do waterproof exterior wall panels typically last?

With proper installation and minimal maintenance, high-quality waterproof exterior wall panels can last 30 years or more, significantly outlasting many traditional siding options.

Can waterproof panels be installed over existing siding?

In some cases, waterproof panels can be installed over existing siding, but this depends on the condition of the current siding and the structural integrity of the wall. A professional assessment is recommended to determine the best approach for your specific situation.

References

1. Building Science Corporation. (2021). "Building Envelope Design Guide - Wall Systems." Whole Building Design Guide. National Institute of Building Sciences.

2. U.S. Department of Energy. (2022). "Guide to Exterior Wall Systems." Energy Saver.

3. American Society of Civil Engineers. (2020). "Exterior Wall Systems: Performance, Design, and Construction." ASCE Library.

4. National Association of Home Builders. (2021). "Cladding Systems for Residential Construction." NAHB Research Center.

5. Journal of Building Engineering. (2022). "Comparative Analysis of Traditional and Modern Exterior Cladding Systems." Elsevier.