- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

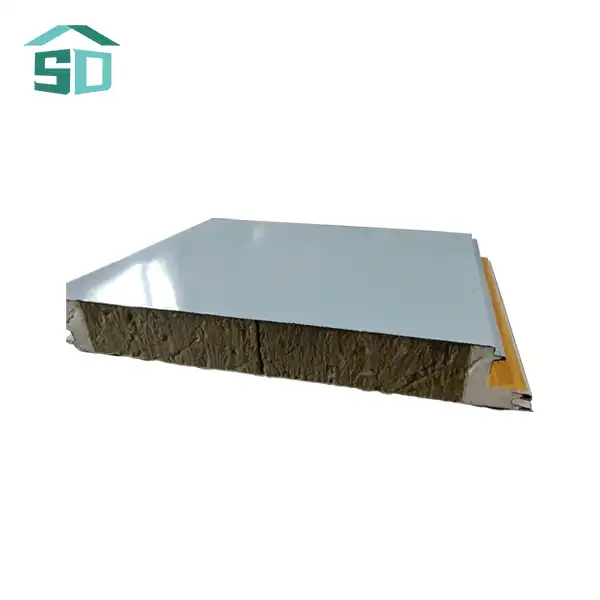

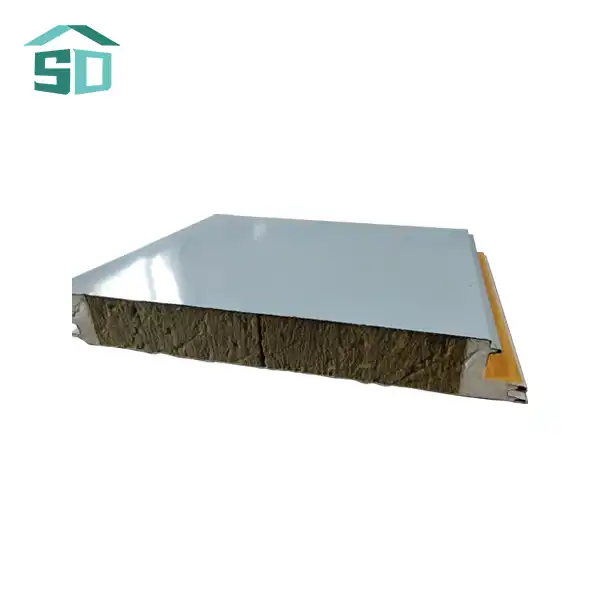

Aluminum Foam Sandwich Panels

Ultimate Durability: Lightweight Yet Robust for Long-Term Performance

Exceptional Insulation: Aluminum Foam Core for Enhanced Thermal Efficiency

Fire-Resistant Safety: Non-Combustible Panels for Secure Spaces

Corrosion-Free Design: Resists Environmental Damage for Lasting Beauty

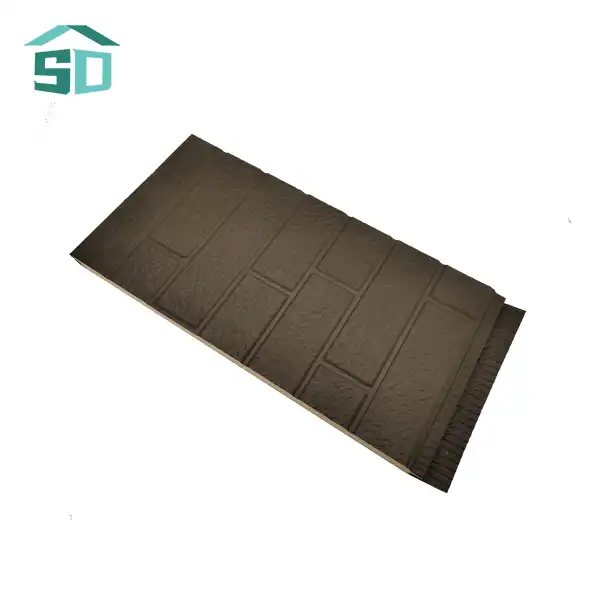

Customizable Looks: Tailor Colors & Patterns to Match Any Décor

Versatile Solution: Ideal for Both Interior & Exterior Wall Applications

Eco-Friendly Insulation: Aluminum Foam Panels with Sustainable Materials

Cost-Effective Choice: Premium Insulation & Durability at Affordable Prices

Product Highlight: Aluminum Foam Sandwich Panels – The Pinnacle of Durability, Insulation, Customization, & Safety for Wall Decorations"

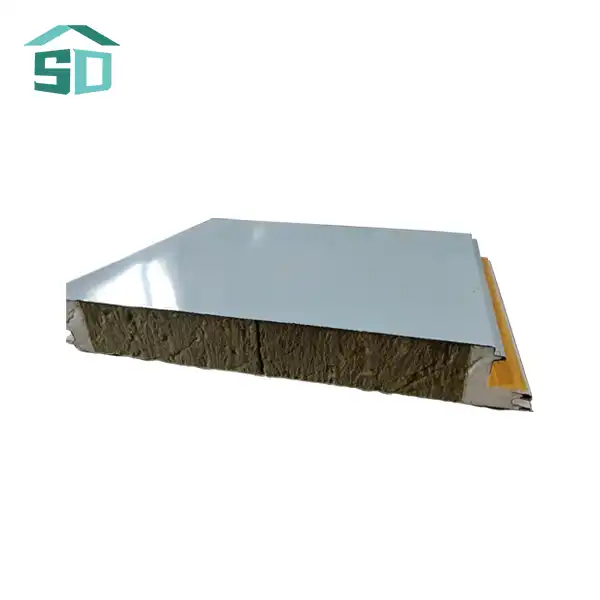

Aluminum Foam Sandwich Panels'Introduction

Aluminum Foam Sandwich Panels, a cutting-edge solution in the realm of building materials. These panels are renowned for their exceptional lightweight properties, excellent thermal insulation, and outstanding strength, making them an ideal choice for various construction projects. At Weifang Sandong Building Materials Co., Ltd., we pride ourselves on delivering top-quality it designed to meet the diverse needs of our customers across the globe.

Product Specifications

| Specification | Details |

|---|---|

| Size Options | Customizable dimensions |

| Thickness | 20mm, 30mm, 40mm, etc. |

| Material | Aluminum, Polyurethane Foam |

| Surface Treatment | Coating, Anodizing |

| Fire Rating | Class A |

| Insulation Material | Polyurethane, Rock Wool |

Product Advantages

- Lightweight yet Durable: It offers significant weight savings without compromising strength, making them easier to handle and install.

- Superior Insulation: These panels provide excellent thermal and sound insulation, ensuring energy efficiency and comfort.

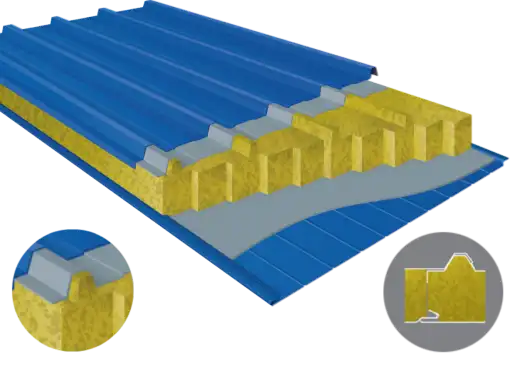

- Versatile Applications: Suitable for both interior and exterior use, they are perfect for walls, roofs, and decorative facades.

- Customizable Designs: Available in various sizes, thicknesses, colors, and surface finishes to meet specific project requirements.

- Eco-Friendly: Made from recyclable materials, they support sustainability efforts in the construction industry.

Technical Features

- High Thermal Performance: They are designed to minimize heat transfer, enhancing energy efficiency.

- Moisture Resistance: With a robust construction, these panels resist moisture and prevent mold growth.

- Fire Resistance: They meet stringent fire safety standards, providing peace of mind in construction projects.

- UV Resistance: The panels maintain their color and structural integrity even when exposed to harsh sunlight.

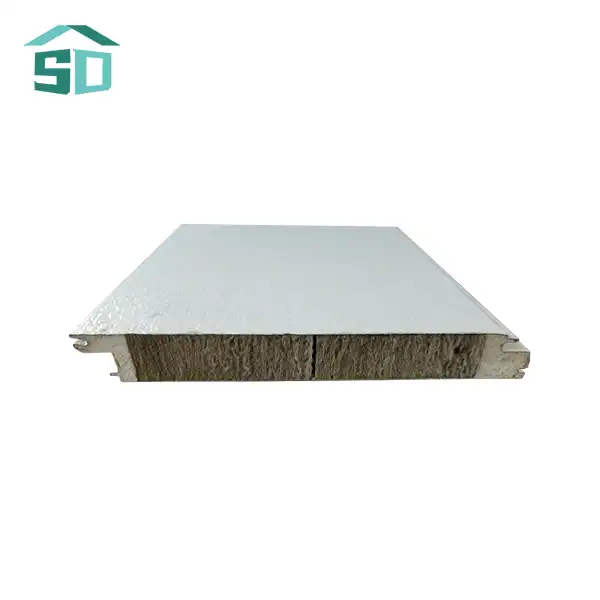

Product Installation

Installing aluminum foam sandwich panels is a straightforward process that can be completed by professional contractors or skilled DIY enthusiasts. Here's a brief overview of the installation steps:

- Preparation: Ensure the surface is clean and dry. Measure and mark where the panels will be installed.

- Cutting: Cut the panels to the desired size using appropriate tools.

- Attachment: Use adhesive or mechanical fasteners to secure the panels to the substrate.

- Sealing: Seal all joints and edges to prevent moisture penetration.

- Finishing: Apply any additional finishing treatments as required.

Product Accessories

- Adhesives and Sealants: Essential for secure installation and moisture prevention.

- Fasteners: Various types are available to suit different substrates.

- Protective Coatings: Optional coatings to enhance durability and aesthetic appeal.

Product Application

They are highly versatile and find applications in various sectors, including:

- Construction: Exterior walls, roofs, and interior wall decorations.

- Industrial: Thermal and sound insulation for machinery and equipment.

- Transportation: Used in vehicles, ships, and aircraft for lightweight insulation.

OEM Service

We offer comprehensive OEM services to tailor our product to meet your specific requirements. Our team will work closely with you to ensure that the product meets your quality standards and design preferences.

FAQ

1. What is it made of?

They are composed of an aluminum outer layer with a foam core, typically polyurethane.

2. Can these panels be customized?

Yes, we provide customization options for size, thickness, color, and surface treatment.

3. What is the fire rating of these panels?

Ours meet Class A fire safety standards.

4. How do I install these Aluminum Foam Sandwich Panels?

Installation can be done using adhesives or mechanical fasteners. Refer to our installation guide for detailed instructions.

5. Are these panels environmentally friendly?

Absolutely! They are made from recyclable materials and contribute to energy efficiency in buildings.

Contact Us

For more information about our Aluminum Foam Sandwich Panels or to discuss your specific needs, please reach out to us at info@sdqsc.com. Our team is ready to assist you with any inquiries or to provide further details on our products.