Grasping Insulated Wall Panels in Challenging Environments

Composition and Structure of Insulated Wall Panels

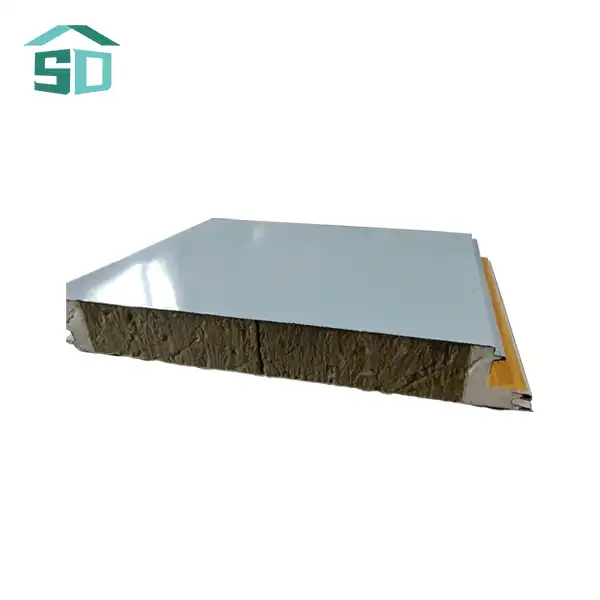

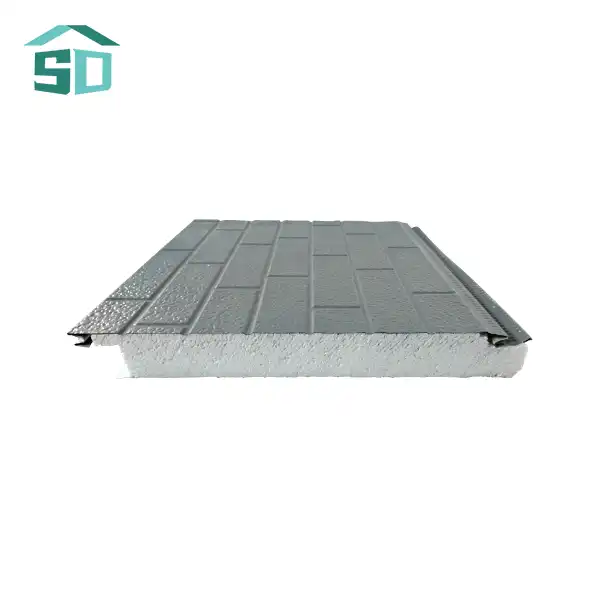

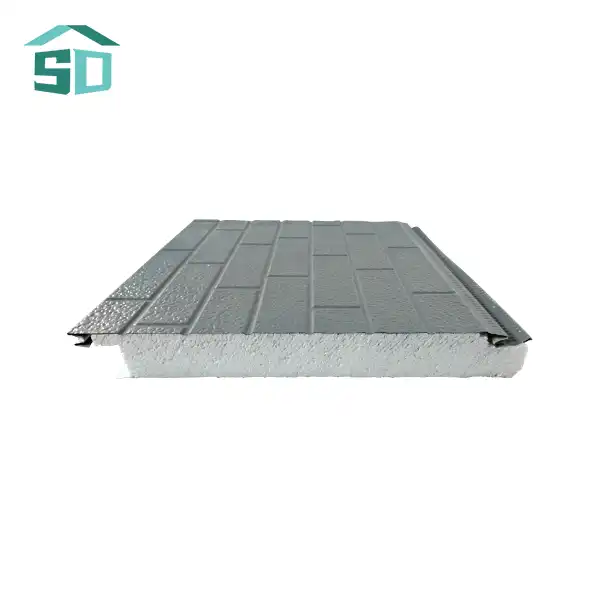

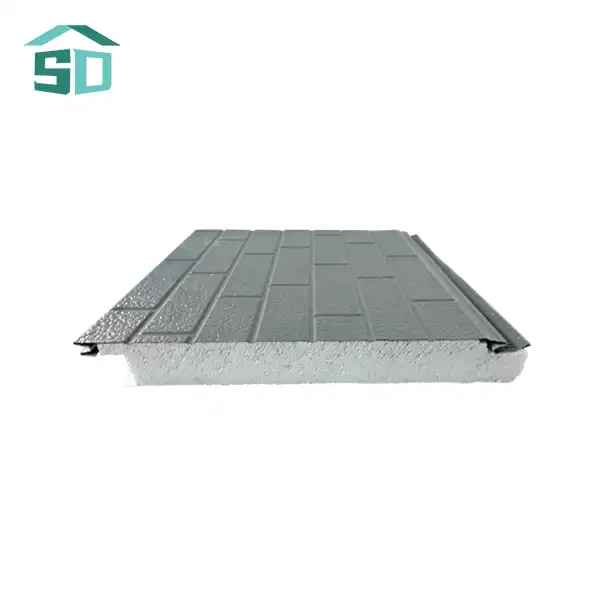

Insulated wall panels are sophisticated building components designed to provide superior thermal insulation and structural support. These panels typically consist of three main elements: an exterior facing, an insulation core, and an interior facing. The exterior facing is often made of metal, such as steel or aluminum, which is treated with corrosion-resistant coatings to withstand harsh environmental conditions. The insulation core, commonly composed of materials like polyurethane foam or mineral wool, offers excellent thermal properties and moisture resistance. The interior facing, which can be metal or a different material depending on the application, completes the sandwich structure.

The unique composition of insulated wall panels allows them to excel in challenging environments. The metal facings provide a robust barrier against external elements, while the insulation core ensures thermal efficiency and helps prevent moisture ingress. This layered structure is key to the panels' ability to maintain their performance in humid or coastal settings.

Moisture Resistance Properties

One of the primary concerns in humid or coastal environments is moisture, which can lead to numerous issues such as mold growth, material degradation, and reduced insulation effectiveness. Insulated wall panels address this challenge through their inherent moisture-resistant properties. The insulation core, particularly when made of closed-cell polyurethane foam, exhibits excellent water repellency. This characteristic prevents water vapor from penetrating the panel, maintaining the integrity of the insulation and the overall structure.

Moreover, the tight sealing between panels during installation creates a continuous barrier against moisture infiltration. This is crucial in coastal areas where driving rain and high humidity levels are common. The moisture resistance of insulated wall panels not only protects the building's interior but also contributes to the longevity of the panels themselves, ensuring they maintain their performance over time.

Corrosion Resistance in Coastal Areas

Coastal environments present a unique challenge due to the presence of salt-laden air, which can accelerate corrosion in many building materials. Insulated wall panels are specifically engineered to combat this issue. The metal facings of these panels are typically treated with advanced corrosion-resistant coatings, such as zinc-aluminum alloys or specialized paint systems. These coatings form a protective layer that shields the metal from salt and other corrosive elements present in coastal atmospheres.

Additionally, some insulated wall panels manufacturers offer panels with stainless steel or aluminum facings, which inherently possess higher corrosion resistance. The choice of these materials further enhances the panels' ability to withstand the aggressive coastal environment without compromising their structural integrity or aesthetic appeal. This corrosion resistance is crucial for maintaining the appearance and functionality of buildings in seaside locations, where traditional materials might quickly deteriorate.

Performance Factors of Insulated Wall Panels in Humid Climates

Thermal Efficiency Maintenance

In humid climates, maintaining thermal efficiency is a significant challenge for many building materials. However, insulated wall panels excel in this aspect due to their unique construction. The insulation core, typically made of materials with low thermal conductivity, remains effective even in high humidity conditions. This is because the closed-cell structure of materials like polyurethane foam prevents moisture absorption, which could otherwise compromise the insulation's performance.

The consistent thermal performance of insulated wall panels in humid environments translates to several benefits. It helps maintain a comfortable indoor temperature, reduces the load on HVAC systems, and contributes to overall energy efficiency. This is particularly valuable in tropical or subtropical regions where managing indoor climate can be energy-intensive. The ability of these panels to maintain their insulating properties in high-humidity conditions makes them an ideal choice for a wide range of buildings, from residential homes to commercial and industrial facilities.

Mold and Mildew Resistance

Mold and mildew growth is a common concern in humid environments, posing risks to both the structural integrity of buildings and the health of occupants. Insulated wall panels offer significant advantages in combating these issues. The non-porous nature of the metal facings and the moisture-resistant properties of the insulation core create an inhospitable environment for mold and mildew growth.

Furthermore, many insulated wall panels are treated with anti-microbial agents during the manufacturing process. These treatments provide an additional layer of protection against the proliferation of mold, mildew, and other microorganisms. The resistance to mold and mildew not only preserves the aesthetic appearance of the building but also contributes to a healthier indoor environment. This feature is particularly valuable in healthcare facilities, food processing plants, and other applications where hygiene is paramount.

Dimensional Stability in Fluctuating Humidity

Fluctuating humidity levels can cause significant dimensional changes in many building materials, leading to warping, buckling, or other forms of distortion. Insulated wall panels, however, demonstrate remarkable dimensional stability even in environments with varying humidity. This stability is attributed to the engineered composition of the panels and the careful selection of materials.

The metal facings of insulated wall panels are largely unaffected by humidity changes, maintaining their shape and size. The insulation core, especially when made of materials like polyurethane foam, exhibits minimal expansion or contraction in response to humidity fluctuations. This dimensional stability ensures that the panels maintain their fit and alignment over time, preserving the building envelope's integrity and aesthetic appearance. It also reduces the risk of gaps or misalignments that could compromise the structure's energy efficiency or weather resistance.

Long-Term Durability and Maintenance Considerations

Lifespan of Insulated Wall Panels in Coastal Settings

The lifespan of insulated wall panels in coastal settings is a testament to their durability and advanced engineering. When properly installed and maintained, these panels can last for several decades, even in the harsh conditions typical of coastal environments. The combination of corrosion-resistant metal facings and moisture-resistant insulation cores contributes to their longevity. In fact, many insulated wall panels manufacturers offer warranties ranging from 20 to 40 years, reflecting their confidence in the product's durability.

It's important to note that the actual lifespan can vary depending on specific environmental conditions, the quality of installation, and the level of maintenance. Factors such as the intensity of UV radiation, the salinity of the air, and the frequency of extreme weather events can influence the panels' longevity. However, compared to traditional building materials, insulated wall panels generally offer superior durability in coastal settings, maintaining their structural integrity and performance characteristics over extended periods.

Maintenance Requirements and Best Practices

While insulated wall panels are known for their low maintenance requirements, proper care can significantly extend their lifespan and preserve their performance, especially in humid or coastal environments. Regular maintenance practices include:

- Periodic Cleaning: Washing the panels with mild detergent and water to remove salt deposits, dirt, and other contaminants that could potentially corrode the surface over time.

- Inspection: Regular visual inspections to check for any signs of damage, such as scratches or dents, which could compromise the protective coatings.

- Sealant Maintenance: Checking and reapplying sealants at joints and penetrations to ensure continued water tightness.

Prompt Repairs: Addressing any damage or issues promptly to prevent more extensive problems from developing.

Additionally, it's advisable to avoid direct contact between the panels and dissimilar metals, which could lead to galvanic corrosion in the presence of moisture. Proper drainage and ventilation around the panels should also be maintained to prevent water accumulation.Cost-Effectiveness Over Time

When evaluating the cost-effectiveness of insulated wall panels in humid or coastal environments, it's essential to consider both the initial investment and the long-term benefits. While the upfront cost of insulated panels may be higher compared to some traditional building materials, their durability and performance characteristics often result in significant long-term savings.

The cost-effectiveness of insulated wall panels stems from several factors:

- Reduced Maintenance Costs: Their resistance to corrosion, mold, and moisture damage translates to lower maintenance and repair expenses over time.

- Energy Savings: The superior insulation properties lead to reduced heating and cooling costs, particularly significant in extreme climates.

- Longevity: The extended lifespan of these panels means less frequent replacement, reducing long-term building costs.

- Structural Integrity: Their ability to maintain performance in challenging environments can prevent costly structural issues that might arise with less durable materials.

Conclusion

Insulated wall panels have proven to be an exceptional choice for buildings in humid or coastal environments. Their unique composition, combining corrosion-resistant facings with moisture-resistant insulation cores, enables them to withstand the challenges posed by high humidity, salt-laden air, and fluctuating environmental conditions. These panels maintain their thermal efficiency, resist mold and mildew growth, and exhibit remarkable dimensional stability even in the most demanding climates. Their long lifespan, coupled with low maintenance requirements, makes them a cost-effective solution for long-term building performance and durability.

As the construction industry continues to seek sustainable and resilient building solutions, insulated wall panels stand out as a reliable option for coastal and humid regions. Their ability to provide superior insulation, structural integrity, and aesthetic appeal while resisting environmental degradation positions them as a forward-thinking choice for architects, builders, and property owners. For those considering exterior cladding solutions that can withstand challenging environments, insulated wall panels offer a compelling combination of performance, durability, and long-term value. To explore how these innovative products can enhance your next building project, we invite you to contact us at info@sdqsc.com for more information on our range of insulated wall panels and other exterior cladding solutions.

FAQ

How long do insulated wall panels typically last in coastal environments?

With proper installation and maintenance, insulated wall panels can last 20-40 years or more in coastal environments, depending on specific conditions and product quality.

Are insulated wall panels suitable for both residential and commercial buildings?

Yes, insulated wall panels are versatile and can be used in various applications, including residential homes, commercial buildings, and industrial facilities.

Do insulated wall panels require special maintenance in humid climates?

While they are low-maintenance, regular cleaning and inspection are recommended to ensure optimal performance and longevity, especially in humid or coastal areas.

References

1. American Iron and Steel Institute. (2021). "Coastal and Industrial Environments." Steel Market Development Institute.

2. Building Science Corporation. (2020). "Moisture Control for Buildings in Hot-Humid Climates."

3. Constructech. (2022). "The Benefits of Insulated Metal Panels in Coastal Environments."

4. Journal of Building Engineering. (2021). "Performance of Insulated Panels in Various Climatic Conditions: A Comprehensive Review."

5. National Institute of Building Sciences. (2022). "Whole Building Design Guide: Building Envelope Design Guide."