Comprehending Thermal Wall Panels: A Game-Changer in Industrial Insulation

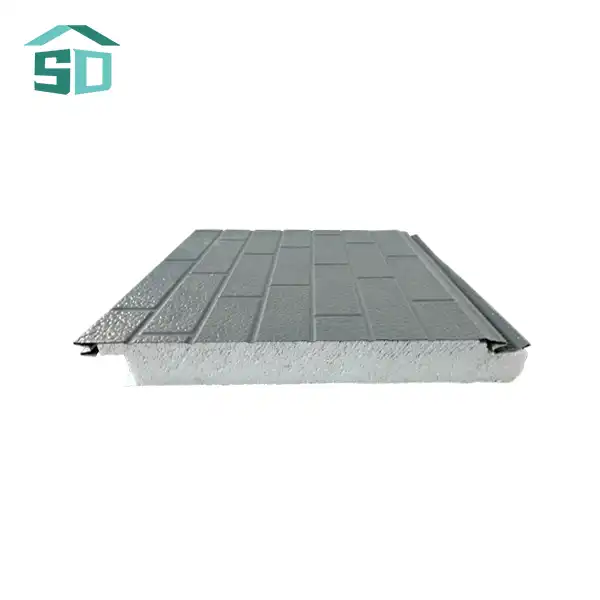

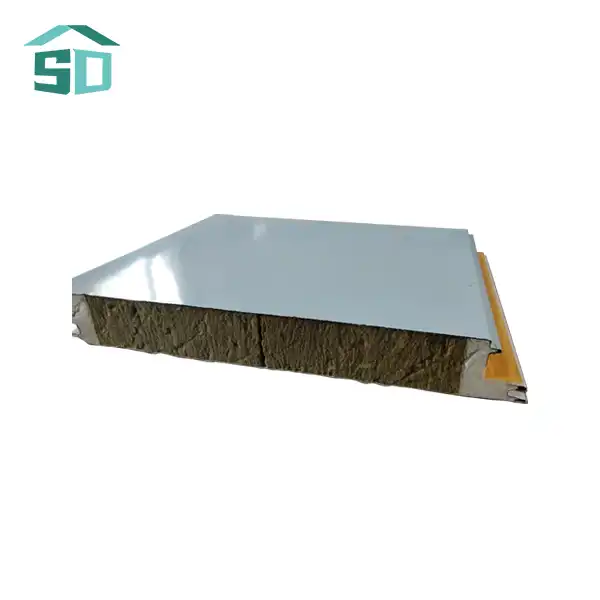

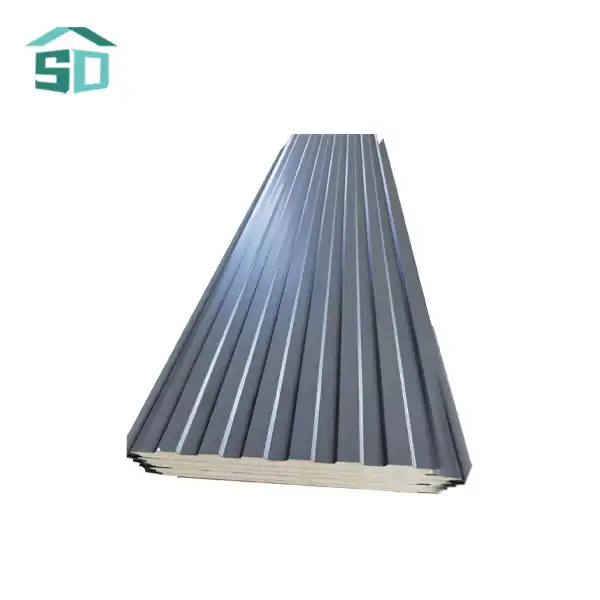

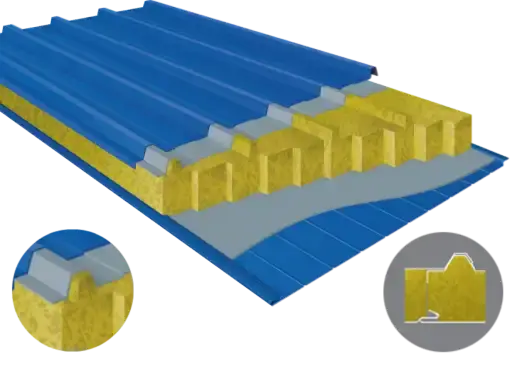

Thermal wall panels represent a significant advancement in building insulation technology. These panels are engineered to provide exceptional thermal resistance, effectively minimizing heat transfer between the interior and exterior of a structure. The core of these panels typically consists of high-performance insulating materials such as polyurethane or rock wool, sandwiched between durable exterior layers made of steel, aluminum, or stainless steel.

The unique composition of thermal wall panels offers several advantages over traditional insulation methods. Their integrated design eliminates thermal bridges, which are common weak points in conventional insulation systems. This results in a more uniform and efficient insulation barrier throughout the entire wall surface. Additionally, the panels' construction allows for quick and easy installation, reducing labor costs and construction time.

Key Features of Thermal Wall Panels

Thermal wall panels boast an impressive array of features that make them ideal for industrial applications:

- High R-value: These panels provide superior thermal resistance, significantly reducing heat loss or gain.

- Moisture resistance: The panels' design prevents moisture penetration, protecting against mold and structural damage.

- Fire resistance: Many thermal wall panels come with fire-retardant properties, enhancing building safety.

- Durability: Engineered to withstand harsh industrial environments, these panels offer long-lasting performance.

- Versatility: Available in various thicknesses (50mm, 75mm, 100mm) and sizes (standard 1200mm x 2400mm or custom), they can be tailored to specific project requirements.

Maximizing Energy Efficiency in Industrial Settings with Thermal Wall Panels

Energy efficiency is a critical concern in industrial facilities, where heating and cooling costs can significantly impact operational expenses. Thermal wall panels address this challenge head-on by providing exceptional insulation performance. The high R-value of these panels ensures that indoor temperatures remain stable, reducing the load on HVAC systems and consequently lowering energy consumption.

In industrial environments where temperature control is crucial, such as food processing plants or pharmaceutical manufacturing facilities, thermal wall panels play a vital role. They help maintain consistent internal temperatures, which is essential for product quality and regulatory compliance. The panels' ability to create an effective thermal barrier also contributes to a more comfortable working environment for employees, potentially boosting productivity.

Cost-Effective Solution for Long-Term Savings

While the initial investment in thermal wall panels may be higher than traditional insulation methods, the long-term benefits far outweigh the upfront costs. The energy savings accrued over time can be substantial, frequently leading to a rapid return on investment for businesses. In addition, the inherent durability and minimal maintenance requirements of these panels reduce overall lifecycle expenses, making them a practical, cost-effective, and economically sustainable solution for demanding industrial applications.

The modular nature of thermal wall panels provides architects and builders with remarkable flexibility for future modifications or building expansions. This adaptability is particularly valuable in commercial or industrial projects, where changing operational needs often require reconfiguration of interior layouts. Because panels can be added, removed, or repositioned without disrupting the overall insulation system, owners benefit from easier renovations, reduced labor costs, and long-term savings throughout the building’s lifecycle.

Environmental Impact and Sustainability of Thermal Wall Panels

In an era where environmental consciousness is paramount, thermal wall panels emerge as a sustainable solution for industrial insulation. Their energy-efficient properties contribute significantly to reducing a building's carbon footprint by lowering overall energy consumption. This aligns with global efforts to combat climate change and adheres to increasingly stringent environmental regulations in the industrial sector.

Many thermal wall panels are manufactured using recyclable materials, further enhancing their environmental credentials. At the end of their lifecycle, these panels can often be recycled, minimizing waste and supporting circular economy principles. The long lifespan of thermal wall panels minimizes the need for frequent replacements, conserving resources, reducing waste from manufacturing and disposal, and ultimately lowering the overall environmental footprint of building projects.

Contribution to Green Building Certifications

The use of thermal wall panels can contribute to achieving green building certifications such as LEED (Leadership in Energy and Environmental Design). These certifications not only demonstrate a commitment to sustainability but can also lead to various benefits including tax incentives, improved public image, and potentially higher property values. The panels' energy efficiency, recyclable components, and contribution to indoor environmental quality align well with the criteria of many green building rating systems.

Conclusion

Thermal wall panels represent a significant leap forward in industrial insulation technology. By offering superior thermal performance, durability, and sustainability, these panels address the complex insulation needs of modern industrial facilities. Their ability to enhance energy efficiency, reduce operational costs, and contribute to environmental sustainability makes them an invaluable asset in industrial construction and renovation projects. As industries continue to prioritize energy conservation and sustainable practices, the adoption of thermal wall panels is likely to increase, setting new standards for industrial insulation.

Are you ready to transform your industrial facility with state-of-the-art thermal wall panels? Discover how our customized solutions can boost your energy efficiency and reduce costs. Contact us at info@sdqsc.com to explore the perfect thermal wall panel solution for your specific needs. Let's work together to create a more efficient, sustainable, and comfortable industrial environment!

FAQ

What are the main benefits of using thermal wall panels in industrial settings?

Thermal wall panels offer superior insulation, energy efficiency, durability, and fire resistance. They help reduce energy costs, maintain consistent temperatures, and contribute to a more comfortable work environment.

How do thermal wall panels compare to traditional insulation methods?

Thermal wall panels provide better insulation performance, faster installation, and often lower long-term costs compared to traditional methods. They also offer integrated moisture and fire resistance.

Are thermal wall panels environmentally friendly?

Yes, thermal wall panels are often made from recyclable materials and significantly reduce energy consumption, contributing to a lower carbon footprint and supporting sustainable building practices.

References

1. U.S. Department of Energy. (2022). "Insulation Materials for Commercial Buildings."

2. American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). (2021). "ASHRAE Handbook - Fundamentals."

3. International Energy Agency. (2023). "Energy Efficiency in Buildings."

4. U.S. Green Building Council. (2023). "LEED v4.1 Building Design and Construction Guide."

5. National Institute of Building Sciences. (2022). "Whole Building Design Guide: Thermal Insulation."