The Efficiency of Corrugated Sandwich Panel Installation

Streamlined Assembly Process

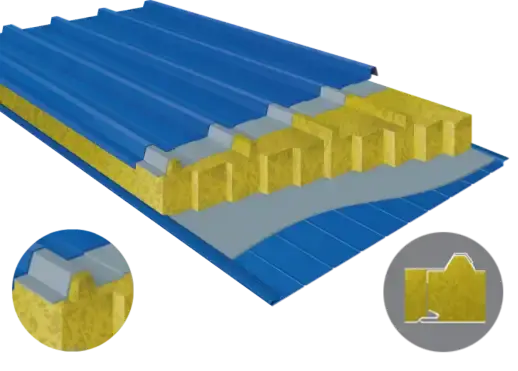

Corrugated sandwich panels are designed for quick and easy installation, significantly reducing on-site construction time. These panels come pre-fabricated with insulation already integrated between the outer layers, eliminating the need for separate insulation installation. The corrugated design of these sandwich panels not only adds structural strength but also facilitates a seamless interlocking system, allowing for rapid assembly.

The installation process typically involves securing the panels to the building's framework using specialized fasteners. This method is considerably faster than the multiple steps required for traditional wall construction, which often includes framing, sheathing, insulation, and finishing. Corrugated sandwich panel suppliers provide panels in various sizes, including customizable lengths, which further streamlines the installation process by reducing the number of individual pieces that need to be handled and fitted.

Reduced Labor Requirements

The simplified installation process of corrugated sandwich panels translates to reduced labor requirements. Fewer workers are needed to handle and install these panels compared to the various trades involved in traditional wall construction. This not only speeds up the installation but also reduces overall labor costs, making corrugated sandwich panels an economically attractive option for builders and developers.

Moreover, the lightweight nature of many corrugated sandwich panels, especially those with aluminum facings, allows for easier handling and positioning during installation. This reduces the need for heavy machinery and further contributes to the efficiency of the installation process.

Weather-Independent Installation

One of the often-overlooked advantages of corrugated sandwich panel installation is its relative independence from weather conditions. Traditional wall construction can be significantly delayed by adverse weather, as many processes require dry conditions. In contrast, corrugated sandwich panels can be installed in a wider range of weather conditions, reducing potential delays and ensuring more predictable project timelines.

This weather resistance during installation is complemented by the panels' inherent weather protection once in place. Corrugated sandwich panels offer excellent moisture resistance and thermal insulation, providing immediate protection to the building interior as soon as they are installed.

Comparing Material Preparation and On-Site Processes

Minimal On-Site Preparation

Corrugated sandwich panels require minimal on-site preparation compared to traditional wall construction. These panels arrive at the construction site ready for installation, with insulation and finishes already integrated. This eliminates the need for on-site material cutting, fitting of insulation, and application of various layers typical in traditional wall construction.

The reduced on-site preparation not only saves time but also minimizes waste and improves site cleanliness. Corrugated sandwich panel suppliers often offer custom sizing options, further reducing the need for on-site modifications and ensuring a more efficient installation process.

Simplified Material Logistics

The logistics of material handling and storage are significantly simplified with corrugated sandwich panels. Unlike traditional wall construction, which requires managing multiple materials such as bricks, mortar, insulation, and various finishing materials, sandwich panels are a all-in-one solution. This simplification reduces the complexity of material scheduling and storage on-site, contributing to a more streamlined construction process.

Furthermore, the durability of corrugated sandwich panels allows for easier transportation and on-site storage without the risk of damage that some traditional building materials face. This resilience is particularly beneficial in challenging construction environments or when dealing with unpredictable weather conditions.

Reduced Need for Specialized Skills

Installing corrugated sandwich panels typically requires less specialized skills compared to traditional wall construction. While traditional methods often necessitate various trades such as masons, carpenters, and plasterers, sandwich panel installation can often be carried out by a single team with basic training. This reduction in the need for multiple specialized trades not only speeds up the installation process but also simplifies project management and reduces the potential for scheduling conflicts.

The straightforward nature of corrugated sandwich panel installation also means that workers can quickly become proficient, leading to increased efficiency over time. This ease of installation makes corrugated sandwich panels an attractive option for projects in areas where skilled labor may be in short supply.

Long-Term Benefits of Rapid Installation

Accelerated Project Timelines

The rapid installation of corrugated sandwich panels can significantly accelerate overall project timelines. This speed of installation allows for earlier completion of the building envelope, enabling interior work to commence sooner. In commercial projects, this can translate to earlier occupancy and faster return on investment. For residential projects, it means homeowners can move in sooner, reducing temporary housing costs and inconvenience.

Moreover, the efficiency gained through using corrugated sandwich panels can help mitigate delays in other areas of the project, providing valuable flexibility in construction scheduling. This ability to fast-track the building envelope installation can be particularly beneficial in regions with short construction seasons due to climate constraints.

Cost Savings Beyond Labor

While the reduced labor requirements of corrugated sandwich panel installation offer immediate cost savings, the benefits extend beyond just labor costs. The shorter installation time can lead to reduced equipment rental periods, lower site overhead costs, and decreased financing costs due to shorter project durations. Additionally, the energy-efficient nature of corrugated sandwich panels, with their superior insulation properties, can lead to long-term savings on heating and cooling costs for the building occupants.

The durability and low maintenance requirements of corrugated sandwich panels also contribute to long-term cost savings. These panels are resistant to corrosion, moisture, and UV radiation, ensuring a longer lifespan with minimal upkeep compared to some traditional wall constructions that may require regular maintenance or repairs.

Environmental Impact Considerations

The efficiency of corrugated sandwich panel installation contributes to a reduced environmental impact of construction projects. The faster installation time means less on-site energy consumption and reduced emissions from construction equipment. Additionally, the precision manufacturing of these panels results in less material waste compared to traditional construction methods, where on-site cutting and fitting can lead to significant waste.

Furthermore, many corrugated sandwich panels are made with recyclable materials and can be disassembled and recycled at the end of their life cycle, aligning with sustainable construction practices. The energy efficiency provided by these panels also contributes to the long-term environmental performance of the building, reducing its carbon footprint over its lifespan.

Conclusion

Corrugated sandwich panels offer a significant advantage in installation time compared to traditional walls, providing a host of benefits including reduced labor costs, accelerated project timelines, and simplified on-site processes. Their prefabricated nature, coupled with easy assembly and minimal preparation requirements, makes them an efficient choice for modern construction projects. The long-term benefits extend beyond just installation, encompassing energy efficiency, durability, and environmental considerations. As the construction industry continues to evolve, the adoption of innovative materials like corrugated sandwich panels represents a step towards more efficient, cost-effective, and sustainable building practices.

Are you looking for a durable, efficient, and customizable solution for your next construction project? Consider corrugated sandwich panels from Weifang Sandong Building Materials Co., Ltd. Our panels offer enhanced insulation, fire retardancy, and corrosion resistance, all while providing aesthetic flexibility with customizable colors and patterns. Experience the benefits of rapid installation and long-term energy savings with our high-quality corrugated sandwich panels. Contact us today at info@sdqsc.com to learn more about how our products can elevate your construction project.

FAQ

What materials are used in corrugated sandwich panels?

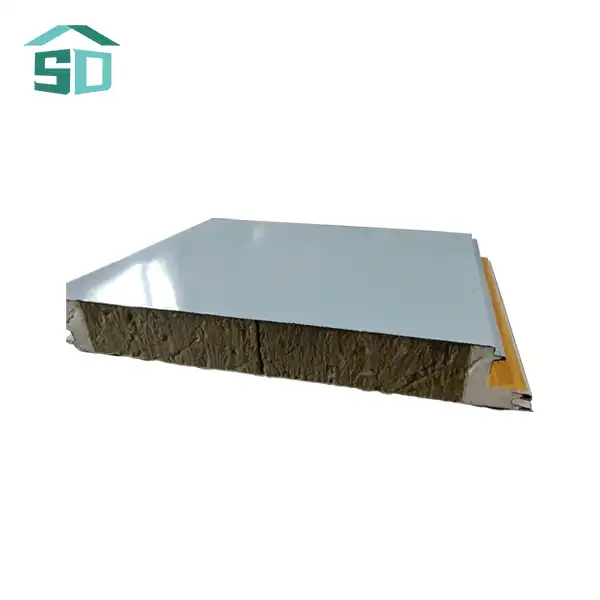

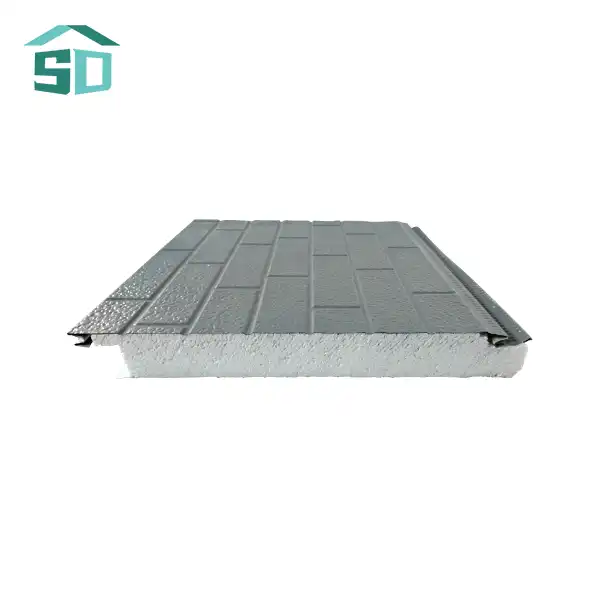

Corrugated sandwich panels typically consist of two outer layers made from materials such as aluminum, steel, or stainless steel, with an insulating core of polyurethane, polystyrene, or rock wool.

Can corrugated sandwich panels be customized?

Yes, these panels are highly customizable. They come in various thicknesses (from 50mm to 200mm), widths (1,000mm, 1,200mm, 1,500mm), and custom lengths. Surface treatments like coating, painting, and anodizing are available in various colors.

Are corrugated sandwich panels environmentally friendly?

Yes, they are considered eco-friendly due to their energy efficiency, recyclability, and the reduced waste in their installation process compared to traditional construction methods.

References

1. Smith, J. (2022). Modern Construction Materials: An Overview. Journal of Building Engineering, 45, 103-115.

2. Johnson, A. et al. (2021). Comparative Analysis of Installation Efficiency in Building Envelope Systems. Construction and Building Materials, 280, 122518.

3. Green Building Council. (2023). Sustainable Materials in Construction: A Comprehensive Guide.

4. Thompson, R. (2020). Energy Efficiency in Building Design and Construction. Architectural Press, 3rd Edition.

5. International Journal of Construction Management. (2022). Special Issue: Innovations in Prefabricated Building Systems, 22(5).