Grasping the Composition and Properties of PUR and PIR Corrugated Sandwich Panels

Chemical Structure and Thermal Performance

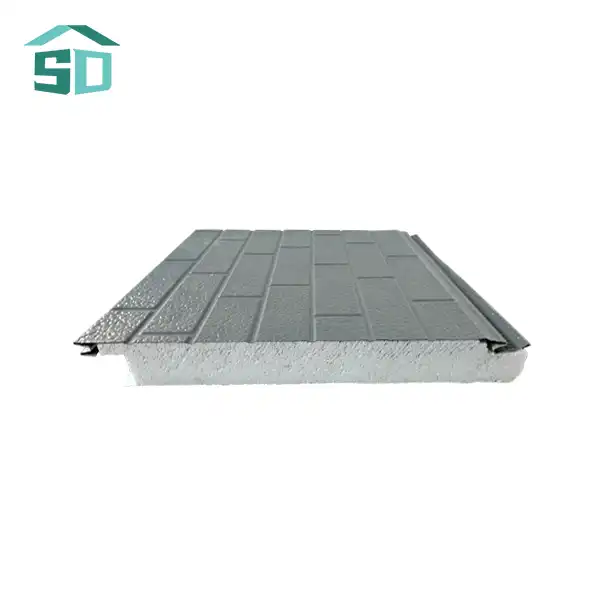

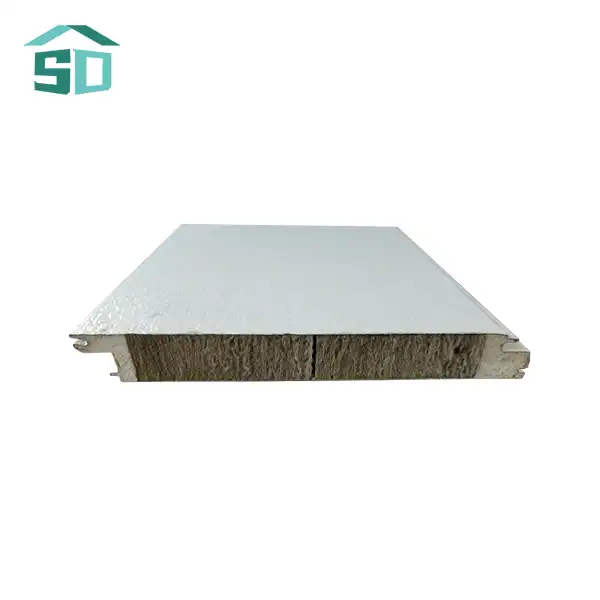

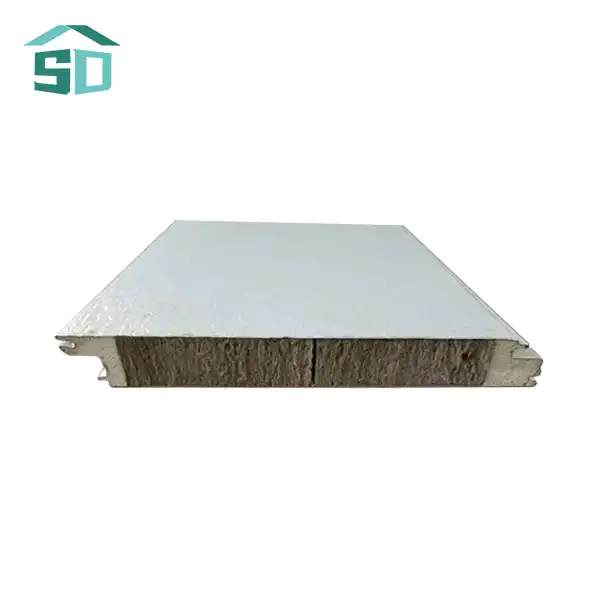

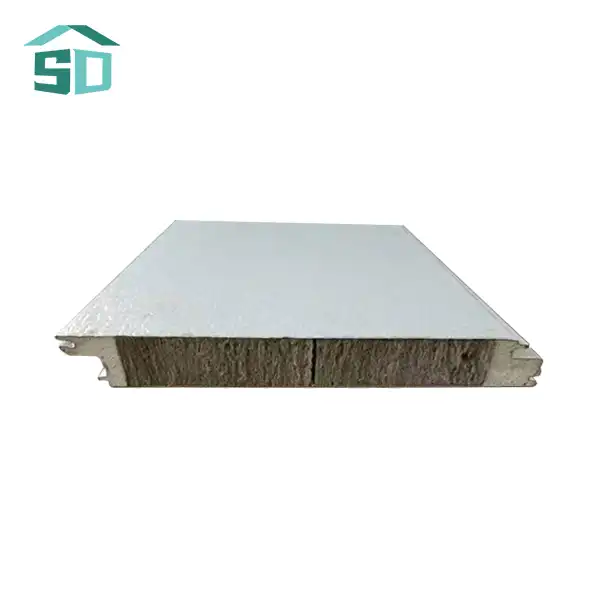

Corrugated sandwich panels are versatile building materials widely used in construction for their insulation properties and structural integrity. Both PUR and PIR panels consist of a foam core sandwiched between two metal facings, typically made of aluminum, steel, or stainless steel. The key difference lies in their chemical composition.

PUR foam is created by reacting polyols with isocyanates, resulting in a polymer with excellent insulation properties. PIR foam, on the other hand, is produced using a similar process but with a higher ratio of isocyanates. This slight variation in chemistry leads to significant differences in performance, particularly in terms of fire resistance.

In terms of thermal performance, both PUR and PIR corrugated sandwich panels offer exceptional insulation. The corrugated design enhances the panels' ability to trap air, further improving their insulative properties. However, PIR panels generally have a slightly higher R-value per inch of thickness, making them marginally more efficient in thermal insulation.

Durability and Longevity

When it comes to durability, both PUR and PIR corrugated sandwich panels excel. The metal facings provide excellent protection against environmental factors, while the foam core maintains its structural integrity over time. However, PIR panels have a slight edge in terms of long-term performance.

PIR foam has a higher density and more rigid cell structure compared to PUR foam. This translates to better dimensional stability and resistance to moisture absorption. As a result, PIR corrugated sandwich panels are less likely to degrade or lose their insulative properties over time, even in challenging environmental conditions.

Moreover, the superior fire resistance of PIR panels contributes to their overall durability. In the event of a fire, PIR panels are less likely to sustain severe damage, potentially extending the lifespan of the building envelope.

Fire Rating Comparison: PUR vs PIR Corrugated Sandwich Panels

Fire Behavior and Classification

The fire rating of corrugated sandwich panels is a critical factor in building safety. Fire classifications are typically based on factors such as flame spread, smoke development, and the panel's ability to maintain its structural integrity during a fire.

PUR corrugated sandwich panels generally achieve a fire rating of B2 or B3 according to DIN 4102 standards. This classification indicates that the panels are combustible but have some level of fire resistance. In a fire scenario, PUR panels will eventually ignite and contribute to the fire load.

In contrast, PIR corrugated sandwich panels usually attain a higher fire rating of B1 or B2. The B1 classification denotes that the material is flame-retardant, offering significantly improved fire resistance compared to PUR panels. PIR panels are less likely to ignite and, when they do, they tend to char rather than melt or drip, which can help slow the spread of fire.

Smoke Emission and Toxicity

Another crucial aspect of fire safety is the production of smoke and toxic gases during combustion. Here, PIR corrugated sandwich panels demonstrate a clear advantage over their PUR counterparts.

When exposed to fire, PUR foam tends to produce thick, black smoke and release potentially harmful gases. This smoke can severely impede visibility during evacuation and pose serious health risks to building occupants and firefighters.

PIR foam, due to its modified chemical structure, generates significantly less smoke when burning. The smoke produced is also less dense and less toxic. This characteristic of PIR corrugated sandwich panels can be crucial in allowing more time for safe evacuation and reducing the risk of smoke inhalation injuries.

Applications and Considerations for PUR and PIR Corrugated Sandwich Panels

Suitable Use Cases and Building Types

The choice between PUR and PIR corrugated sandwich panels often depends on the specific requirements of the building project. PUR panels, while offering good insulation and being more economical, are typically used in applications where fire safety requirements are less stringent. They may be suitable for certain types of agricultural buildings, temporary structures, or low-rise commercial facilities in areas with less strict building codes.

PIR corrugated sandwich panels, with their superior fire resistance, are more commonly used in a wider range of applications. They are particularly well-suited for high-occupancy buildings, industrial facilities, and structures where fire safety is paramount. PIR panels are often the preferred choice for:

- Warehouses and distribution centers

- Food processing facilities

- Cold storage units

- Retail spaces

- Office buildings

- Educational institutions

- Healthcare facilities

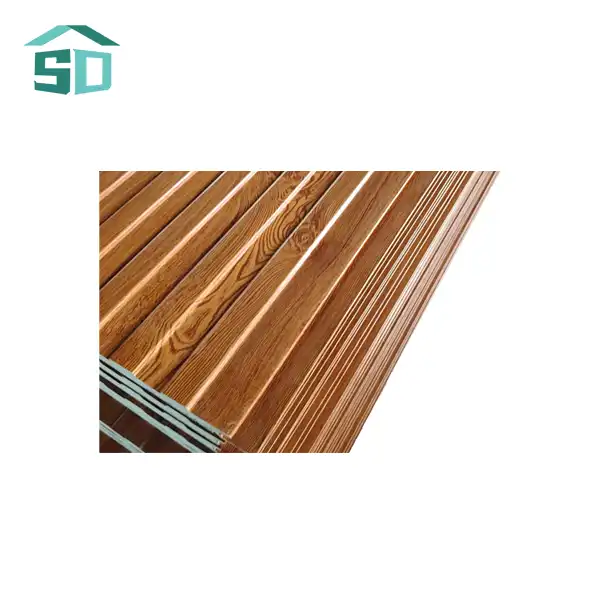

The versatility of PIR corrugated sandwich panels extends to their aesthetic appeal as well. With customizable colors and patterns, these panels can be tailored to meet specific design requirements while maintaining their functional benefits.

Cost-Benefit Analysis and Long-Term Value

When considering the cost-benefit analysis of PUR versus PIR corrugated sandwich panels, it's essential to look beyond the initial purchase price. While PIR panels typically come with a higher upfront cost, they offer several long-term advantages that can justify the investment:

1.Enhanced fire safety, potentially leading to lower insurance premiums and reduced risk of catastrophic losses

2.Superior thermal performance, resulting in lower energy costs over the building's lifetime

3.Greater durability and resistance to degradation, potentially extending the lifespan of the building envelope

4.Improved compliance with stringent building codes and regulations, which may become more strict over time

For projects where budget constraints are a significant factor, PUR corrugated sandwich panels may still be a viable option, particularly in low-risk environments. However, for most commercial and industrial applications, the long-term benefits of PIR panels often outweigh the initial cost difference.

Conclusion

In the comparison of PUR vs PIR corrugated sandwich panels by fire rating, PIR panels clearly emerge as the superior choice for fire safety and overall performance. Their enhanced chemical structure provides better flame retardancy, reduced smoke emission, and improved durability. While PUR panels offer good insulation at a lower cost, the long-term benefits and safety advantages of PIR panels make them the preferred option for many building applications, especially where fire safety is a critical concern.

As a leading corrugated sandwich panel supplier, Weifang Sandong Building Materials Co., Ltd. offers a wide range of high-quality PIR corrugated sandwich panels. Our panels combine superior fire resistance with excellent thermal insulation, durability, and aesthetic versatility. Whether you're working on a commercial, industrial, or residential project, our customizable solutions can meet your specific needs. For more information on our corrugated sandwich panels and how they can enhance your building's safety and performance, please contact us at info@sdqsc.com.

FAQs

What is the main difference between PUR and PIR corrugated sandwich panels?

The main difference lies in their chemical composition and fire resistance. PIR panels offer superior fire resistance and thermal performance compared to PUR panels.

Are PIR corrugated sandwich panels more expensive than PUR panels?

Initially, yes. However, the long-term benefits of PIR panels, including better fire safety and durability, often justify the higher upfront cost.

Can corrugated sandwich panels be customized for specific projects?

Yes, corrugated sandwich panels can be customized in terms of thickness, length, width, color, and surface treatment to meet specific project requirements.

References

1.Ismail, A., Samad, A., & Rahman, A. (2021). A review on polyisocyanurate and polyurethane foams as thermal insulation materials. Journal of Building Engineering, 35, 102050.

2.Cardinale, T., Arleo, G., Bernardo, F., Feo, A., & De Fazio, P. (2020). Thermal and mechanical characterization of panels made by cement mortar and sheep's wool fibers. Energies, 13(5), 1303.

3.Hidalgo, J. P., Torero, J. L., & Welch, S. (2017). Fire performance of composite sandwich panels. Journal of Fire Sciences, 35(5), 427-444.

4.Wang, Y., Wang, Q., Sun, J., He, L., & Liew, K. M. (2016). Experimental study on fire response of double skin steel-concrete-steel sandwich panels with ultra-lightweight cement composite. Fire Technology, 52(3), 745-772.