The Science Behind Fireproof Insulation Panels

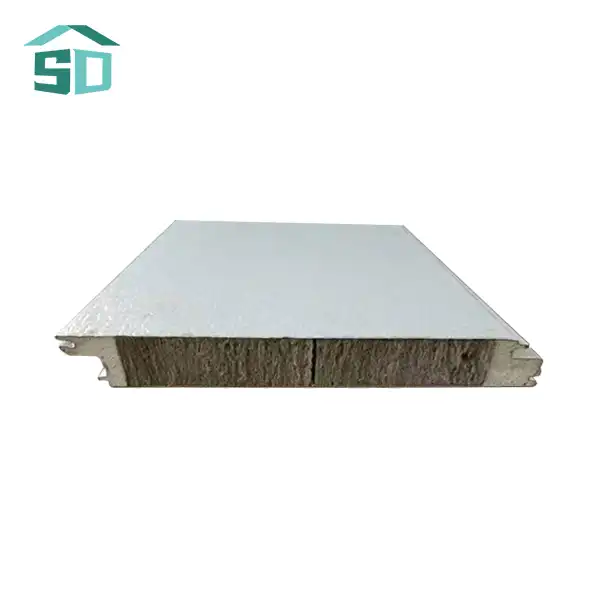

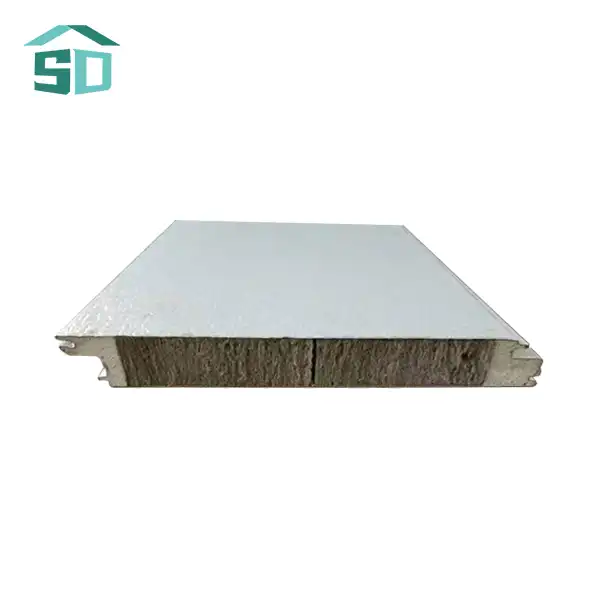

Fireproof insulation panels are marvels of modern engineering, designed to provide exceptional protection against heat and flame. These panels typically consist of a core material sandwiched between two metal facings, creating a robust barrier against fire and thermal transfer. The core is often made from non-combustible materials such as mineral wool, which has excellent fire-resistant properties and can withstand temperatures up to 1000°C without melting or degrading.

The metal facings, usually aluminum or steel, contribute to the panel's overall strength and durability. These facings are treated with special coatings that enhance their resistance to corrosion and UV radiation, ensuring long-lasting performance even in harsh environments. The combination of these materials results in a panel that not only resists fire but also provides superior insulation, reducing heat transfer and improving energy efficiency in buildings.

Fire Resistance Ratings and Standards

Fireproof insulation panels undergo rigorous testing to ensure they meet stringent fire safety standards. These panels are rated according to their ability to withstand fire and prevent its spread. Common fire resistance ratings include A1, A2, B1, and B2, as per EN 13501-1 standards. The highest rating, A1, indicates that the material is non-combustible and will not contribute to fire propagation under any circumstances.

In addition to fire resistance, these panels are also evaluated for their thermal performance, structural integrity, and acoustic properties. Certifications such as ISO, CE, and UL provide further assurance of the panels' quality and compliance with international safety standards. These comprehensive evaluations ensure that fireproof insulation panels meet the demanding requirements of modern construction projects, particularly those in extreme conditions.

Applications in Extreme Environments

Fireproof insulation panels excel in extreme environments where traditional building materials may falter. In industrial settings, such as oil refineries or chemical plants, these panels provide crucial protection against potential fire hazards. Their ability to contain fires and prevent structural collapse can be lifesaving in such high-risk areas.

In regions prone to wildfires, fireproof roof insulation panels offer an additional layer of defense for residential and commercial buildings. By resisting ignition and slowing the spread of fire, these panels can significantly enhance a structure's chances of surviving a wildfire event. This makes them an increasingly popular choice in fire-prone areas of Australia, California, and other regions experiencing increased wildfire activity due to climate change.

Arctic and Desert Applications

Extreme temperature environments, such as the Arctic or desert regions, also benefit from the unique properties of fireproof insulation panels. In the Arctic, these panels provide excellent thermal insulation, helping to maintain stable indoor temperatures in the face of extreme cold. Their moisture-resistant properties also prevent issues related to condensation and ice formation, which can be detrimental to building integrity in polar climates.

In desert environments, fireproof insulation panels help combat the intense heat and solar radiation. Their reflective surfaces and high insulation values significantly reduce heat gain, leading to more comfortable indoor environments and reduced cooling costs. The panels' resistance to UV degradation ensures they maintain their performance and appearance over time, even under constant exposure to harsh sunlight.

Installation and Maintenance Considerations

Proper installation of fireproof insulation panels is crucial to ensure their optimal performance in extreme conditions. The installation process typically involves securing the panels to the building's structural framework using specialized fasteners. Careful attention must be paid to sealing joints and penetrations to maintain the integrity of the fire barrier and insulation properties.

Many manufacturers offer comprehensive installation guides and training programs to ensure contractors are well-versed in the correct installation techniques. Some even provide on-site support for complex projects or those in particularly challenging environments. This level of support helps guarantee that the panels perform as intended, providing maximum protection and efficiency.

Long-term Performance and Maintenance

One of the key advantages of fireproof insulation panels is their low maintenance requirements. Once properly installed, these panels can maintain their performance characteristics for decades with minimal intervention. Regular visual inspections are recommended to check for any signs of damage or wear, particularly in extreme environments where the panels may be subjected to harsh conditions.

In the event of minor damage, such as small dents or scratches, repairs can often be made without compromising the panel's fire-resistant properties. For more significant damage, individual panels can typically be replaced without the need to overhaul the entire system. This modular nature contributes to the long-term cost-effectiveness of fireproof insulation panel systems, making them an attractive option for projects where durability and longevity are paramount.

Conclusion

Fireproof roof insulation panels represent a significant advancement in building technology, offering unparalleled protection against extreme conditions. Their combination of fire resistance, thermal insulation, and durability makes them an ideal choice for a wide range of applications, from industrial facilities to residential buildings in high-risk areas. As climate change continues to present new challenges to the built environment, the importance of such innovative materials cannot be overstated. By providing a robust defense against fire and extreme temperatures, these panels contribute to safer, more resilient structures capable of withstanding the harshest conditions our planet can produce.

Are you looking to enhance the safety and efficiency of your building project with fireproof insulation panels? Weifang Sandong Building Materials Co., Ltd. offers a comprehensive range of high-quality fireproof insulation panels suitable for various applications. Our products combine durability, superior insulation, and unmatched fire safety to meet your specific needs. For more information or to discuss your project requirements, please contact us at info@sdqsc.com.

FAQ

What makes fireproof insulation panels different from standard insulation?

Fireproof insulation panels are specifically designed to resist fire and prevent its spread, in addition to providing thermal insulation. They're made with non-combustible materials and undergo rigorous testing to meet fire safety standards.

How long do fireproof insulation panels typically last?

With proper installation and maintenance, fireproof insulation panels can last for several decades. Their durability and resistance to environmental factors contribute to their long lifespan.

Are fireproof insulation panels environmentally friendly?

Many manufacturers prioritize sustainability in their production processes. Some panels are made with recyclable materials and contribute to energy efficiency in buildings, reducing overall environmental impact.

Can fireproof insulation panels be used in residential buildings?

Yes, these panels are suitable for both commercial and residential applications, especially in areas prone to wildfires or extreme weather conditions.

How do I choose the right fireproof insulation panel for my project?

Consider factors such as the specific fire rating required, thermal insulation needs, local building codes, and the environmental conditions the panels will be exposed to. Consulting with a professional or contacting a manufacturer directly can help you make the best choice.

References

1.National Fire Protection Association. (2021). NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components.

2.International Code Council. (2021). International Building Code.

3.European Committee for Standardization. (2018). EN 13501-1: Fire classification of construction products and building elements.

4.Underwriters Laboratories. (2020). UL 263: Standard for Fire Tests of Building Construction and Materials.

5.American Society for Testing and Materials. (2019). ASTM E119-20: Standard Test Methods for Fire Tests of Building Construction and Materials.