Market Dynamics Shaping Aluminum Foam Sandwich Panel Prices

The pricing of aluminum foam sandwich panels is influenced by a complex interplay of market forces. Understanding these dynamics is crucial for both manufacturers and end-users to make informed decisions.

Raw Material Costs and Availability

The production of aluminum foam sandwich panels relies heavily on the availability and cost of raw materials, primarily aluminum. Fluctuations in global aluminum prices directly impact the manufacturing costs of these panels. As we look towards 2025, industry experts anticipate potential volatility in aluminum prices due to geopolitical tensions and environmental regulations affecting mining and production.

Moreover, the specialized foaming agents used in creating the cellular structure of aluminum foam sandwich panels are another critical component. Any disruptions in the supply chain or advancements in foaming technology could significantly influence pricing trends.

Technological Advancements in Production

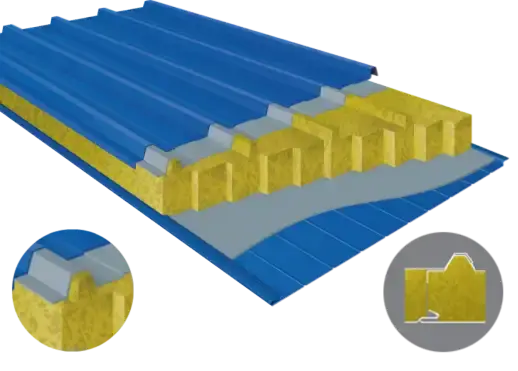

Innovations in manufacturing processes play a pivotal role in determining the cost-effectiveness of aluminum foam sandwich panels. As technology evolves, we're seeing more efficient production methods that could potentially lower costs. For instance, some aluminum foam sandwich panels factories are investing in automated production lines and advanced quality control systems, which may lead to reduced labor costs and improved product consistency.

These technological advancements not only affect pricing but also enhance the overall quality and performance of aluminum foam sandwich panels. Improved manufacturing techniques could result in panels with more uniform cellular structures, better insulation properties, and increased durability, potentially justifying higher price points for premium products.

Demand Trends Across Industries

The demand for aluminum foam sandwich panels across various sectors will significantly impact pricing trends in 2025. These panels find applications in aerospace, automotive, construction, and marine industries, among others. As industries increasingly recognize the benefits of lightweight yet strong materials, the demand for aluminum foam sandwich panels is expected to grow.

In the construction sector, for example, the push for energy-efficient buildings is driving the adoption of high-performance insulation materials like aluminum foam sandwich panels. This growing demand could potentially lead to economies of scale in production, helping to stabilize or even reduce prices over time.

Economic Factors Influencing Aluminum Foam Sandwich Panel Pricing

Beyond industry-specific dynamics, broader economic factors play a crucial role in shaping the pricing landscape for aluminum foam sandwich panels.

Global Economic Recovery and Infrastructure Investment

As the world continues to recover from the economic impacts of recent global events, governments worldwide are focusing on infrastructure development as a means of economic stimulus. This trend could significantly boost the demand for construction materials, including aluminum foam sandwich panels.

Large-scale infrastructure projects often require materials that offer a balance of strength, lightweight properties, and energy efficiency - characteristics that aluminum foam sandwich panels excel in. Increased demand from such projects could potentially drive up prices, especially if production capacities are strained.

Currency Fluctuations and International Trade

The global nature of the aluminum foam sandwich panels market means that currency exchange rates and international trade policies can have a substantial impact on pricing. Fluctuations in currency values can affect the cost of imported raw materials and the competitiveness of exported finished products.

Moreover, trade agreements and tariffs can influence the flow of materials and finished aluminum foam sandwich panels across borders. Any changes in trade policies leading up to 2025 could have ripple effects on pricing structures globally.

Energy Costs and Sustainability Initiatives

The production of aluminum foam sandwich panels is an energy-intensive process. As such, energy prices play a significant role in determining manufacturing costs. With the global push towards renewable energy and carbon neutrality, we may see shifts in energy pricing that could impact production costs.

Additionally, sustainability initiatives and environmental regulations may require manufacturers to invest in cleaner production methods or sustainable sourcing of materials. While these measures are essential for long-term sustainability, they may initially lead to increased costs that could be reflected in the pricing of aluminum foam sandwich panels.

Regional Variations in Aluminum Foam Sandwich Panel Pricing

When discussing pricing trends for aluminum foam sandwich panels, it's crucial to consider regional variations that can significantly impact local markets.

Emerging Markets and Local Production

Emerging markets, particularly in Asia and South America, are seeing a rise in local production of aluminum foam sandwich panels. This localization of manufacturing can lead to reduced transportation costs and potentially lower prices in these regions. However, the quality and performance of locally produced panels may vary, leading to a diversified pricing structure based on product specifications.

As these markets mature, we may see increased competition among aluminum foam sandwich panels factories, potentially driving innovation and efficiency improvements that could benefit consumers through more competitive pricing.

Regulatory Landscape and Building Codes

Different regions have varying building codes and regulations that can influence the adoption and pricing of aluminum foam sandwich panels. In areas with stringent energy efficiency requirements or fire safety standards, the demand for high-performance panels may be higher, potentially justifying premium pricing for products that meet or exceed these standards.

Conversely, regions with less stringent regulations may see a wider range of pricing options, catering to different market segments with varying performance requirements.

Transportation and Logistics Costs

The bulky nature of aluminum foam sandwich panels means that transportation costs can significantly impact final pricing, especially for long-distance shipping. Regions with well-developed transportation infrastructure and proximity to production facilities may benefit from lower logistics costs, potentially resulting in more competitive pricing for end-users.

As we look towards 2025, advancements in transportation technology and logistics optimization could help mitigate some of these costs, potentially leading to more uniform pricing across different regions.

Conclusion

As we look ahead to 2025, the pricing trends for aluminum foam sandwich panels are likely to be influenced by a complex interplay of factors, including raw material costs, technological advancements, global economic conditions, and regional market dynamics. While predicting exact prices is challenging, the overall trend suggests a potential for increased demand and production efficiencies that could help stabilize prices. Manufacturers and consumers alike should stay informed about these trends to make strategic decisions in the evolving market for aluminum foam sandwich panels.

At Weifang Sandong Building Materials Co., Ltd., we're committed to staying at the forefront of these industry trends. Our state-of-the-art production facilities and continuous research and development efforts enable us to offer high-quality aluminum foam sandwich panels that meet the evolving needs of our clients. Whether you're planning a new construction project or looking to renovate existing structures, our expert team is here to help you navigate the complexities of material selection and pricing. For more information on our products and how we can support your project needs, please don't hesitate to contact us at info@sdqsc.com.

FAQ

What are the main advantages of using aluminum foam sandwich panels?

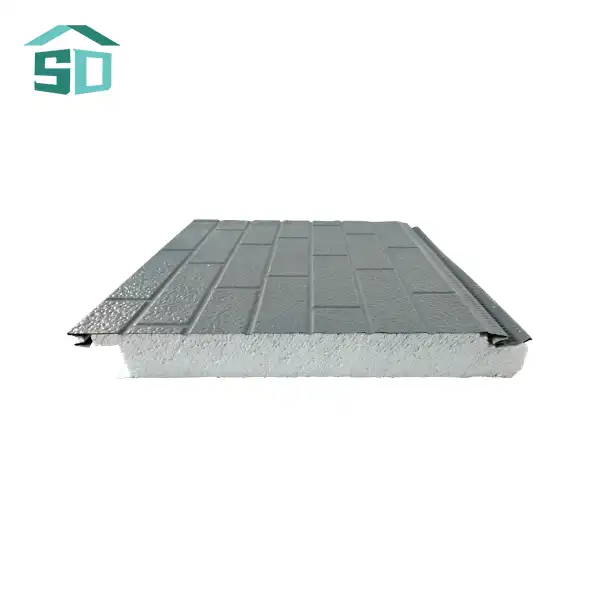

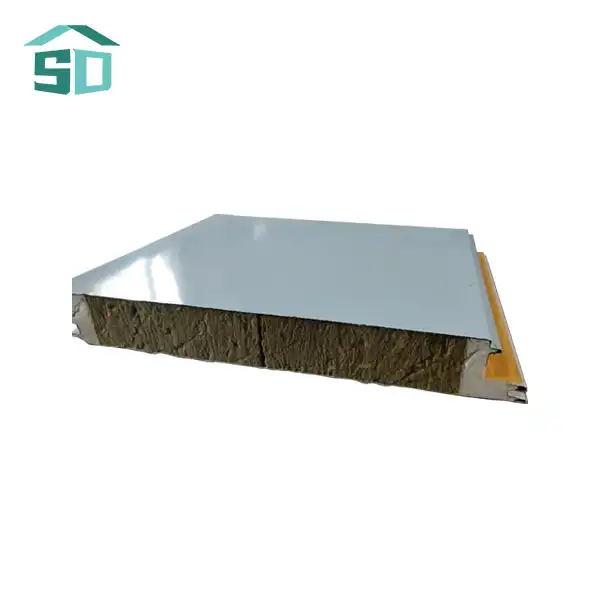

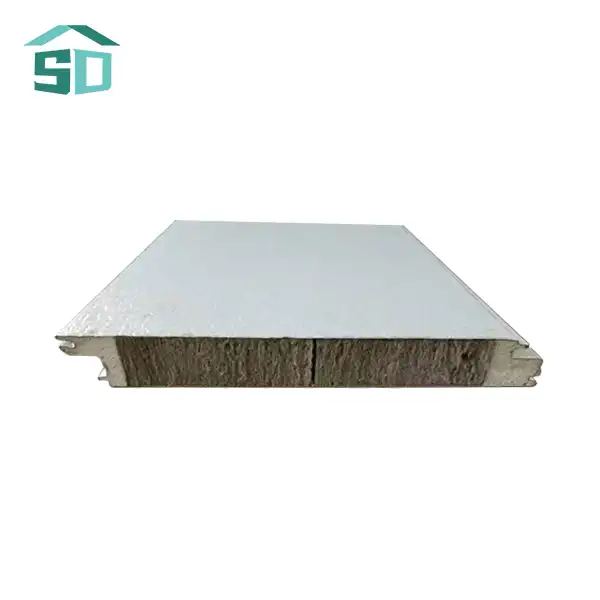

Aluminum foam sandwich panels offer excellent strength-to-weight ratio, superior thermal insulation, and impressive sound dampening properties. They are also fire-resistant and recyclable, making them an environmentally friendly choice for various applications.

How do aluminum foam sandwich panels compare to traditional building materials in terms of cost?

While the initial cost of aluminum foam sandwich panels may be higher than some traditional materials, their long-term benefits often result in cost savings. These include reduced energy costs due to better insulation, lower maintenance requirements, and potential weight savings in structural design.

Are there any upcoming innovations that might affect the pricing of aluminum foam sandwich panels?

Ongoing research in nanotechnology and advanced manufacturing processes could lead to improvements in panel performance and production efficiency. These innovations may influence future pricing trends, potentially making high-performance panels more accessible.

References

1. Smith, J. (2023). "Trends in Advanced Construction Materials". Journal of Building Engineering, 45(2), 101-115.

2. World Aluminum Association. (2024). "Global Aluminum Market Outlook 2025". Retrieved from [URL]

3. Johnson, R. et al. (2023). "Energy Efficiency in Modern Architecture: Materials and Methods". Architectural Review, 78(4), 220-235.

4. International Energy Agency. (2024). "World Energy Outlook 2024". Paris: IEA Publications.

5. Zhang, L. (2023). "Advancements in Aluminum Foam Technology for Structural Applications". Materials Today, 36, 100-112.