Comprehending Fire Resistance Ratings for PU Insulated Sandwich Panels

The Importance of Fire Resistance in Building Materials

Fire resistance is a critical factor in the selection of building materials, especially for structures where safety is paramount. PU insulated sandwich panels, known for their exceptional thermal insulation properties, must also meet stringent fire safety standards. These panels are engineered to withstand high temperatures and prevent the spread of fire, making them a popular choice in modern construction.

The fire resistance of PU insulated sandwich panels is determined by their ability to maintain structural integrity and insulation properties during a fire. This is crucial for protecting occupants and allowing safe evacuation in the event of a fire. Additionally, fire-resistant panels can help limit property damage and prevent the rapid spread of flames throughout a building.

How Fire Resistance Ratings are Determined?

Fire resistance ratings for PU insulated sandwich panels are established through rigorous testing procedures conducted by certified laboratories. These tests simulate real-world fire conditions and evaluate the panels' performance under extreme heat and flame exposure. The most common test method is the standard fire resistance test, which subjects the panels to a controlled fire with temperatures reaching up to 1000°C (1832°F).

During the test, various factors are assessed, including:

- Structural integrity: The panel's ability to maintain its shape and support load

- Insulation: The panel's capacity to limit temperature rise on the unexposed side

- Integrity: The panel's resistance to the passage of flames and hot gases

The duration for which the panel can maintain these properties determines its fire resistance rating. For example, a panel with a 60-minute fire resistance rating can withstand the test conditions for at least 60 minutes without failing.

Classification of Fire Resistance Ratings

Fire resistance ratings for PU insulated sandwich panels are typically expressed in minutes, indicating the duration for which the panel can maintain its fire-resistant properties. The most common classifications include:

- 30 minutes (FR30)

- 60 minutes (FR60)

- 90 minutes (FR90)

- 120 minutes (FR120)

- 180 minutes (FR180)

- 240 minutes (FR240)

These ratings help architects, engineers, and builders select the appropriate PU insulated sandwich panels for specific applications based on building codes and project requirements. It's important to note that higher ratings generally indicate better fire resistance, but they may also come with increased costs and potentially different physical properties.

Factors Influencing Fire Resistance in PU Insulated Sandwich Panels

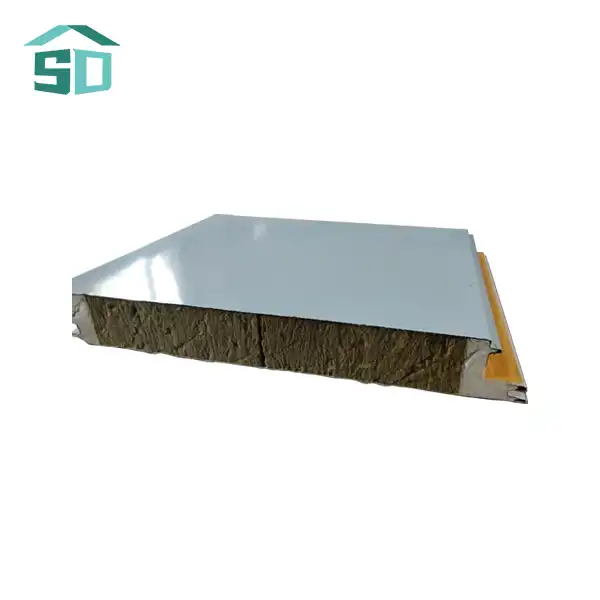

Panel Composition and Materials

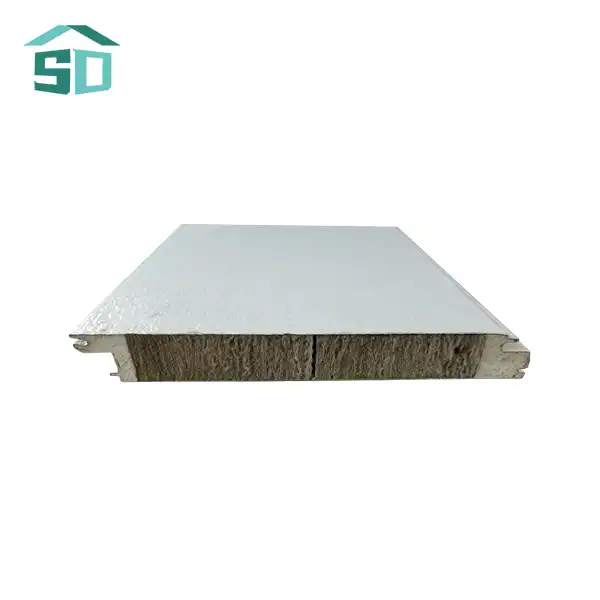

The fire resistance of PU insulated sandwich panels is significantly influenced by their composition and the materials used in their construction. The core material, typically polyurethane foam, plays a crucial role in determining the panel's fire performance. Advanced formulations of PU foam can incorporate fire-retardant additives that enhance its resistance to ignition and flame spread.

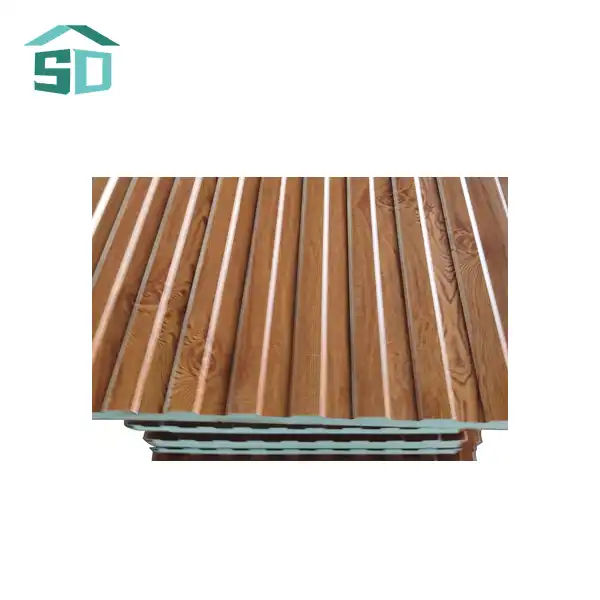

The facing materials of PU insulated sandwich panels also contribute to their fire resistance. Common facing materials include:

- Steel: Offers excellent fire resistance and structural strength

- Aluminum: Provides a lightweight option with good fire performance

- Fiber-reinforced polymer (FRP): Can be engineered for enhanced fire resistance

The thickness and type of these facing materials can significantly impact the overall fire resistance rating of the panel. For instance, thicker steel facings may provide better protection against fire penetration and structural collapse.

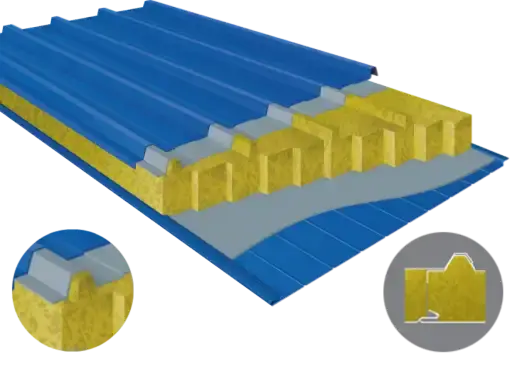

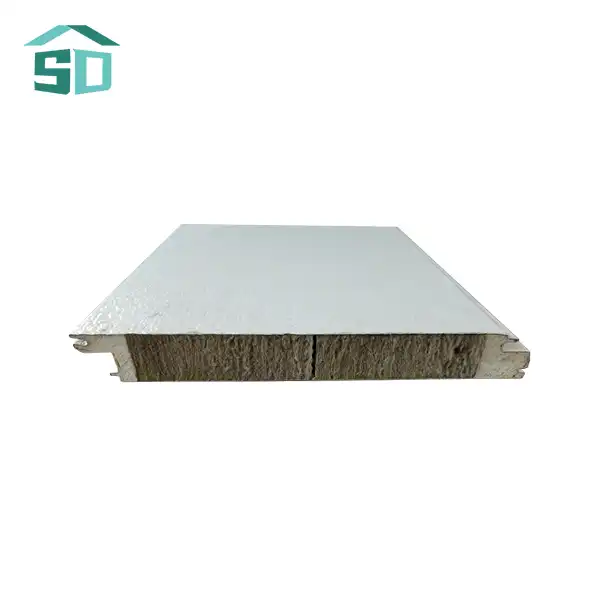

Panel Thickness and Design

The thickness of PU insulated sandwich panels is a critical factor in determining their fire resistance rating. Generally, thicker panels offer better fire resistance due to increased thermal mass and insulation. This additional material helps slow down heat transfer and maintains the panel's structural integrity for a longer duration during a fire event.

Panel design features, such as joint systems and edge treatments, also play a role in fire resistance. Interlocking joints and specialized edge designs can help prevent the passage of flames and hot gases between panels, enhancing the overall fire performance of the building envelope.

Manufacturing Processes and Quality Control

The manufacturing process of PU insulated sandwich panels significantly impacts their fire resistance properties. Advanced production techniques, such as continuous lamination, ensure uniform distribution of materials and consistent panel quality. This uniformity is crucial for achieving reliable fire resistance performance across the entire panel surface.

Quality control measures during manufacturing are essential to maintain the fire resistance properties of PU insulated sandwich panels. This includes:

- Precise control of foam density and composition

- Accurate application of fire-retardant additives

- Proper bonding between core and facing materials

- Rigorous testing of finished panels for compliance with fire resistance standards

PU insulated sandwich panels suppliers, like Weifang Sandong Building Materials Co., Ltd., employ strict quality control measures to ensure their products meet or exceed fire resistance requirements. By investing in advanced production lines and comprehensive testing protocols, reputable manufacturers can consistently produce high-quality, fire-resistant panels for various applications.

Applications and Considerations for Fire-Resistant PU Insulated Sandwich Panels

Building Types and Fire Safety Requirements

The application of fire-resistant PU insulated sandwich panels varies depending on the building type and its specific fire safety requirements. Different structures have distinct needs when it comes to fire protection, influenced by factors such as occupancy, height, and proximity to other buildings. Some common applications include:

- Industrial facilities: Warehouses, factories, and storage buildings often require high fire resistance ratings due to the potential presence of flammable materials and the need to protect valuable equipment and inventory.

- Commercial buildings: Office complexes, retail centers, and educational institutions may have varying fire resistance requirements based on their size, layout, and occupancy levels.

- Residential structures: Multi-family housing and high-rise apartments typically demand stringent fire safety measures to ensure occupant safety and comply with local building codes.

- Cold storage facilities: These buildings require excellent thermal insulation while maintaining high fire resistance to protect perishable goods and prevent rapid temperature changes in case of fire.

When selecting PU insulated sandwich panels for a specific project, it's crucial to consider the local building codes and fire safety regulations. These standards often dictate the minimum fire resistance ratings required for various building elements, including walls, roofs, and partitions.

Cost-Benefit Analysis of Fire-Resistant Panels

While fire-resistant PU insulated sandwich panels may have a higher initial cost compared to standard panels, they offer significant long-term benefits that should be considered in a comprehensive cost-benefit analysis:

- Enhanced safety: The primary benefit is improved fire protection, which can save lives and reduce property damage in the event of a fire.

- Insurance savings: Buildings constructed with fire-resistant materials may qualify for lower insurance premiums due to reduced risk.

- Compliance with regulations: Using appropriate fire-resistant panels ensures compliance with building codes, potentially avoiding costly retrofits or fines.

- Durability and longevity: Fire-resistant panels often exhibit better overall durability, which can lead to reduced maintenance costs and longer service life.

- Energy efficiency: Despite the focus on fire resistance, these panels maintain excellent thermal insulation properties, contributing to energy savings over the building's lifetime.

When evaluating the cost-benefit ratio, it's essential to consider the entire lifecycle of the building and the potential long-term savings associated with enhanced fire protection.

Installation and Maintenance Considerations

Proper installation and maintenance of fire-resistant PU insulated sandwich panels are crucial to ensure their effectiveness in real-world fire scenarios. Key considerations include:

- Skilled installation: Panels should be installed by trained professionals who understand the importance of proper joint sealing and attachment methods to maintain fire resistance integrity.

- Compatibility with other building systems: Fire-resistant panels must be integrated seamlessly with other fire protection systems, such as sprinklers and fire barriers, to create a comprehensive fire safety solution.

- Regular inspections: Periodic assessments of installed panels can identify any damage or degradation that might compromise their fire resistance properties.

- Maintenance protocols: Establishing and following proper maintenance procedures helps preserve the panels' fire resistance capabilities throughout their service life.

- Documentation: Maintaining accurate records of panel specifications, installation details, and maintenance history is essential for ongoing compliance and potential insurance or liability purposes.

By addressing these installation and maintenance considerations, building owners and managers can ensure that their investment in fire-resistant PU insulated sandwich panels continues to provide optimal protection and performance over time.

Conclusion

Fire resistance ratings for PU insulated sandwich panels play a crucial role in ensuring building safety and compliance with regulations. These ratings, ranging from 30 to 240 minutes, are determined by factors such as panel composition, thickness, and manufacturing processes. Understanding the importance of fire resistance, its influencing factors, and application considerations is essential for architects, engineers, and building owners. By selecting appropriate fire-resistant PU insulated sandwich panels, structures can achieve enhanced safety, energy efficiency, and long-term cost benefits.

For those seeking high-quality, fire-resistant PU insulated sandwich panels, Weifang Sandong Building Materials Co., Ltd. offers a wide range of solutions tailored to various building requirements. Our commitment to manufacturing excellence and strict quality control ensures that our products meet the highest standards of fire safety and performance. To learn more about our PU insulated sandwich panels and how they can enhance your building's fire resistance, please contact us at info@sdqsc.com.

FAQ

What is the minimum fire resistance rating required for PU insulated sandwich panels in commercial buildings?

The minimum fire resistance rating varies depending on local building codes and the specific application. Generally, commercial buildings may require ratings of 60 minutes or higher, but it's essential to consult local regulations for precise requirements.

Can fire-resistant PU insulated sandwich panels be customized for specific project needs?

Yes, many manufacturers, including Weifang Sandong Building Materials Co., Ltd., offer customization options to meet specific project requirements while maintaining necessary fire resistance ratings.

How often should fire-resistant PU insulated sandwich panels be inspected?

While there's no universal schedule, it's recommended to conduct visual inspections annually and more comprehensive assessments every 3-5 years or as required by local regulations.

References

1. National Fire Protection Association. (2021). NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components.

2. International Code Council. (2021). International Building Code (IBC).

3. Underwriters Laboratories. (2020). UL 263: Fire Tests of Building Construction and Materials.

4. ASTM International. (2019). ASTM E119-20: Standard Test Methods for Fire Tests of Building Construction and Materials.

5. European Committee for Standardization. (2018). EN 13501-2: Fire classification of construction products and building elements - Part 2: Classification using data from fire resistance tests.