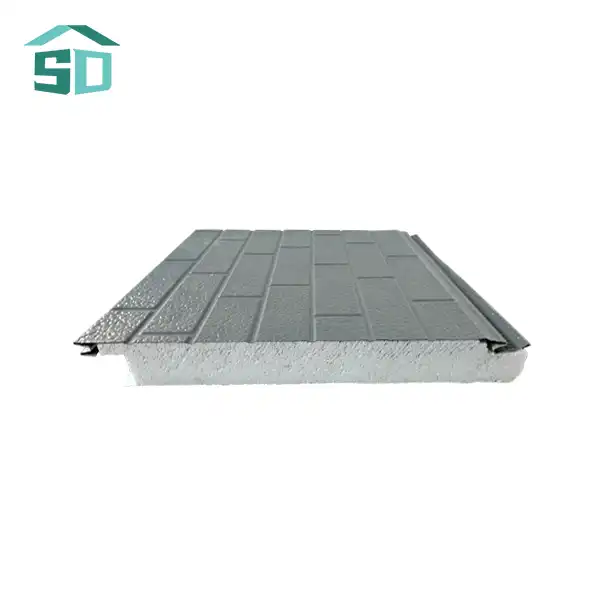

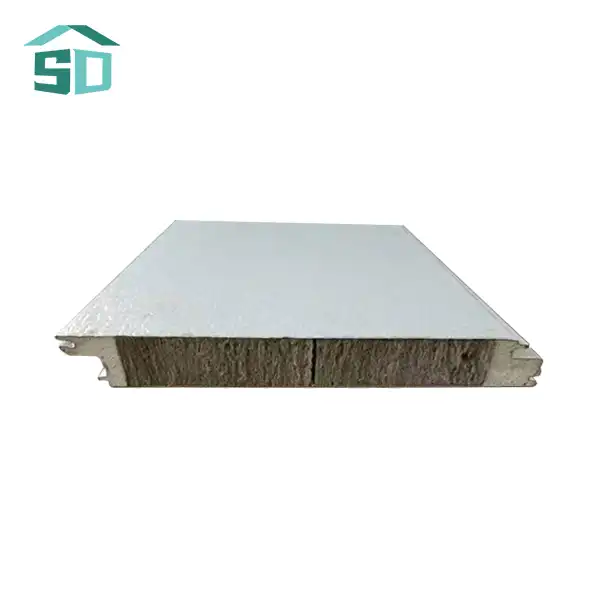

The Composition and Manufacturing Process of PU Insulation Boards

PU insulation boards are crafted through a sophisticated chemical reaction between polyol and isocyanate compounds. This reaction results in the formation of a rigid foam with closed-cell structures, which is the key to its impressive insulating properties. The manufacturing process involves carefully controlled conditions to ensure consistent quality and performance.

Raw Materials and Chemical Reactions

The primary components in PU insulation board production are polyols and isocyanates. When these chemicals are combined under specific conditions, they undergo an exothermic reaction, expanding and forming a rigid foam structure. This expansion process is critical in creating the closed-cell structure that gives PU its exceptional insulating properties.

Production Techniques and Quality Control

Modern PU insulation board manufacturing employs advanced production lines and rigorous quality control systems. The process involves precise mixing of raw materials, controlled expansion, and curing. Throughout production, manufacturers conduct comprehensive inspections, checking factors such as thickness uniformity, mechanical strength, and overall product appearance. This meticulous approach ensures that each PU insulation board meets stringent quality standards.

Customization Options

One of the advantages of PU insulation boards is the ability to customize various aspects of the product. Manufacturers can adjust the density, thickness, and even incorporate additives to enhance specific properties such as fire resistance or moisture resistance. This flexibility allows PU insulation boards to be tailored for a wide range of applications, from residential construction to industrial facilities.

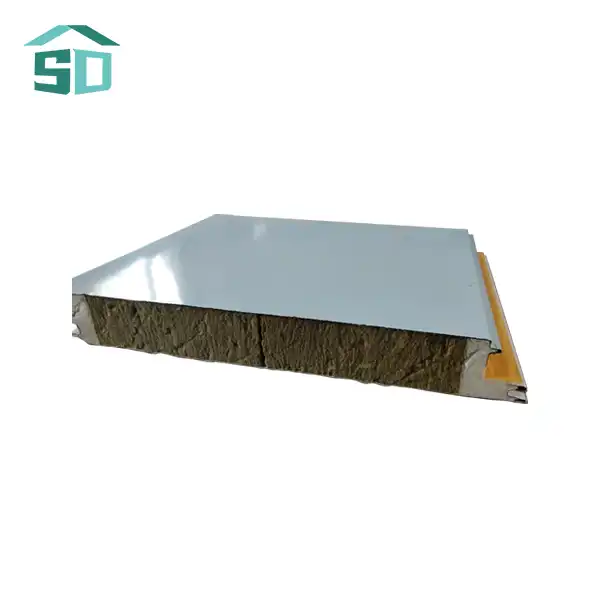

Thermal Performance and Energy Efficiency of PU Insulation Boards

The thermal performance of PU insulation boards is one of their most notable attributes, making them a popular choice in the construction industry. Their unique structure and composition contribute to their superior insulating capabilities, translating into significant energy savings for buildings.

Thermal Conductivity and R-Value

PU insulation boards boast an impressive thermal conductivity rating of approximately 0.022 W/m·K. This low thermal conductivity translates to a high R-value, which measures the material's resistance to heat flow. The exceptional R-value of PU insulation boards means that they can provide effective insulation even with relatively thin layers, allowing for space-efficient designs in construction projects.

Long-Term Thermal Performance

A key advantage of PU insulation boards is their ability to maintain thermal performance over time. The closed-cell structure of the foam resists the infiltration of air and moisture, which can degrade insulating properties in other materials. This stability ensures that buildings insulated with PU boards continue to benefit from energy savings throughout their lifespan.

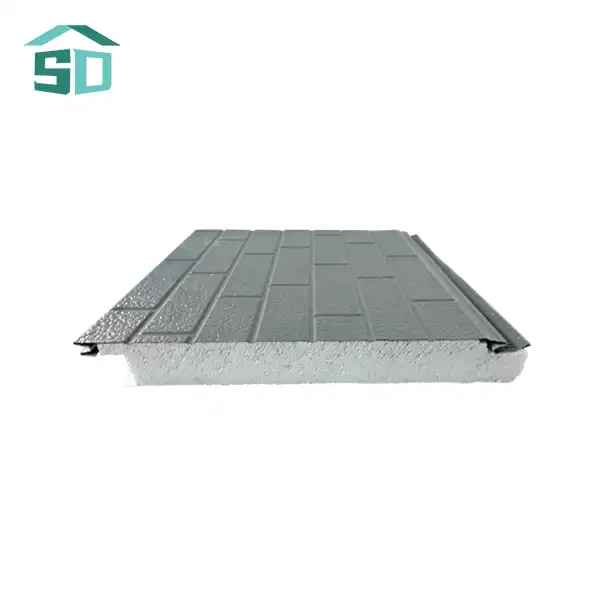

Energy Savings and Environmental Impact

The high insulating efficiency of PU boards contributes significantly to energy conservation in buildings. By reducing heat loss in winter and heat gain in summer, these boards help decrease the energy demand for heating and cooling systems. This not only leads to lower energy bills for building occupants but also contributes to reduced carbon emissions, aligning with global efforts for sustainable construction practices.

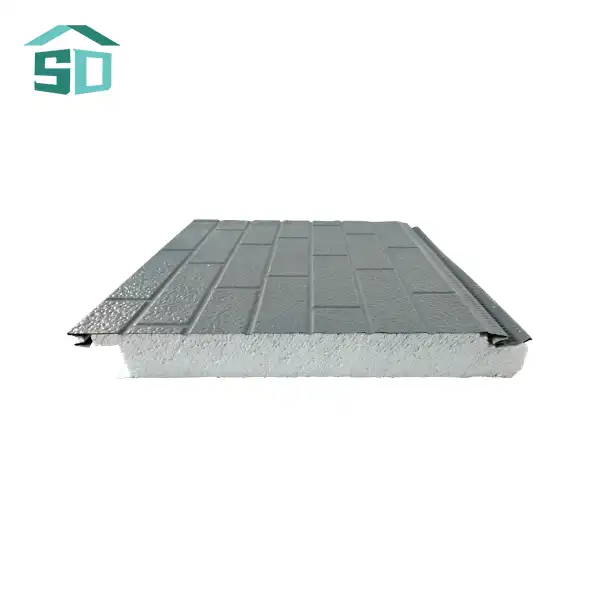

Applications and Installation of PU Insulation Boards

The versatility of PU insulation boards makes them suitable for a wide range of applications in both residential and commercial construction. Their ease of installation and adaptability to various surfaces further enhance their appeal in the building industry.

Residential Applications

In homes, PU insulation boards find use in walls, roofs, and floors. They are particularly effective in creating comfortable living spaces by maintaining consistent indoor temperatures. The boards can be easily integrated into both new construction and renovation projects, offering homeowners an efficient solution for improving their property's energy performance.

Commercial and Industrial Uses

PU insulation boards excel in commercial and industrial settings where thermal management is crucial. They are commonly used in office buildings, warehouses, and manufacturing facilities. The boards' ability to withstand heavy loads without compromising performance makes them ideal for flat roof applications in commercial structures.

Installation Techniques and Best Practices

Installing PU insulation boards is a straightforward process that can be accomplished with basic tools and techniques. The process typically involves cutting the boards to size, applying adhesive, and securing them in place. Proper sealing of joints and gaps is crucial to maximize insulation efficiency. Many manufacturers offer complementary accessories such as specialized adhesives, sealants, and fasteners to ensure optimal installation and performance.

Conclusion

PU insulation boards stand out as a versatile and highly effective solution for thermal insulation in various construction applications. Their superior thermal performance, durability, and ease of installation make them an attractive choice for both residential and commercial projects. The ability to customize PU boards to meet specific project requirements further enhances their utility in the construction industry. As energy efficiency continues to be a priority in building design and renovation, PU insulation boards are likely to play an increasingly important role in creating sustainable, comfortable, and energy-efficient structures.

At Weifang Sandong Building Materials Co., Ltd., we are committed to providing top-quality PU insulation boards that meet the highest standards of performance and sustainability. Our products are designed to offer superior thermal insulation, fire safety, and durability, making them an ideal choice for your construction needs. Whether you're working on a residential project or a large-scale commercial development, our PU insulation boards can help you achieve your energy efficiency goals. For more information about our products and how they can benefit your next project, please don't hesitate to contact us at info@sdqsc.com.

FAQs

What is the typical lifespan of PU insulation boards?

PU insulation boards can last for several decades when properly installed and maintained, often outlasting the building's lifespan.

Are PU insulation boards environmentally friendly?

While the production process has environmental impacts, the energy savings over the product's lifetime often offset these, making them a net positive choice for the environment.

Can PU insulation boards be recycled?

Yes, many PU insulation boards can be recycled at the end of their life, contributing to circular economy practices in construction.

How do PU insulation boards compare to traditional insulation materials?

PU insulation boards generally offer superior thermal performance and space efficiency compared to traditional materials like fiberglass or mineral wool.

References

1. European Isocyanate Producers Association. (2021). "Polyurethanes: Sustainable Materials for Energy Efficient Buildings."

2. Building Science Corporation. (2020). "Thermal Performance of Building Envelope Materials."

3. International Journal of Low-Carbon Technologies. (2019). "Life Cycle Assessment of Insulation Materials in Buildings."

4. American Chemistry Council. (2022). "Polyurethanes in Construction: Performance and Sustainability."

5. Journal of Building Engineering. (2021). "Comparative Analysis of Insulation Materials for Energy-Efficient Buildings."