Introducing Rust on Corrugated Steel Siding Panels

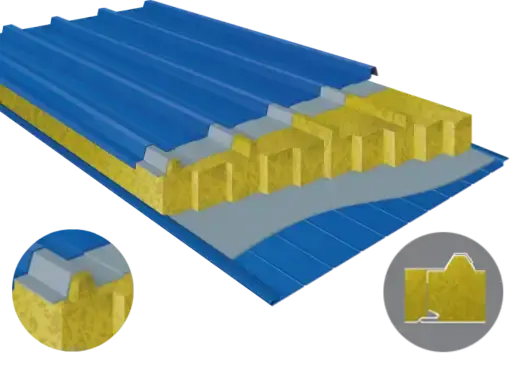

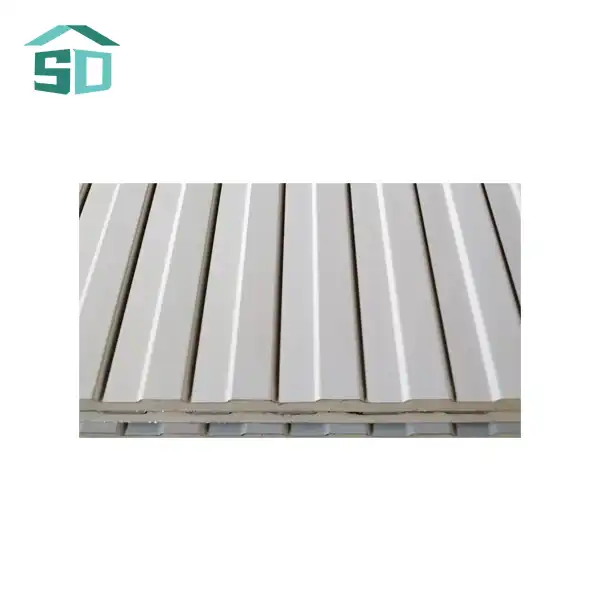

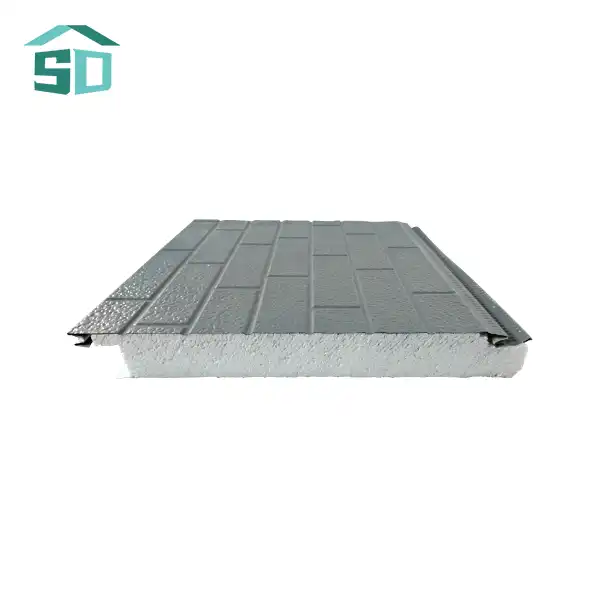

Corrugated steel siding panels are renowned for their strength, durability, and versatility in architectural applications. However, even these robust materials can succumb to rust over time, especially in harsh environmental conditions. Understanding the causes and implications of rust on corrugated steel siding panels is crucial for effective maintenance and repair.

Causes of Rust on Corrugated Steel Siding

Rust formation on corrugated steel siding panels is primarily due to prolonged exposure to moisture and oxygen. Several factors can accelerate this process:

- Environmental factors: Coastal areas with high salt content in the air, industrial zones with corrosive pollutants, and regions with high humidity levels are particularly prone to rust formation.

- Physical damage: Scratches, dents, or chips in the protective coating can expose the underlying steel to moisture, initiating the rusting process.

- Age and wear: Over time, the protective galvanized coating on corrugated steel siding panels can wear thin, making the metal more susceptible to rust.

- Poor maintenance: Neglecting regular cleaning and inspections can allow rust to develop unnoticed.

Impact of Rust on Siding Performance

Rust on corrugated steel siding panels is more than just an aesthetic issue. It can significantly impact the performance and longevity of your siding:

- Structural integrity: As rust progresses, it can weaken the steel, compromising the structural strength of the siding panels.

- Insulation properties: Rusted areas can create gaps or holes, reducing the siding's ability to insulate effectively.

- Water resistance: Rust can create entry points for moisture, potentially leading to interior damage and further corrosion.

- Aesthetic appeal: Visible rust spots can detract from the overall appearance of the building, potentially decreasing property value.

Corrugated steel siding panels factory production often includes corrosion-resistant treatments, but these can wear off over time. Regular inspection and prompt addressing of rust issues are essential for maintaining the siding's performance and appearance.

Step-by-Step Guide to Repairing Rusted Corrugated Steel Siding Panels

Repairing rusted corrugated steel siding panels requires a systematic approach to ensure effective restoration. Follow these steps to repair and blend rusted areas seamlessly:

Preparation and Cleaning

Before beginning the repair process, proper preparation is crucial:

- Safety first: Wear protective gear, including gloves, safety goggles, and a dust mask.

- Inspect the damage: Assess the extent of rust damage to determine if repair is feasible or if panel replacement is necessary.

- Clean the area: Use a wire brush or sandpaper to remove loose rust and debris. For larger areas, consider using a power washer.

- Degrease: Apply a degreasing agent to remove any oils or residues that could interfere with the repair proces

- Rinse and dry: Thoroughly rinse the cleaned area with water and allow it to dry completely.

Rust Treatment and Repair

Once the area is clean and dry, proceed with the rust treatment:

- Apply rust converter: Use a high-quality rust converter to chemically change the rust into a more stable compound. This also helps prevent future rusting.

- Allow to cure: Let the rust converter dry completely according to the manufacturer's instructions.

- Sand smooth: Lightly sand the treated area to create a smooth surface for priming and painting.

- Apply metal primer: Use a primer specifically designed for metal surfaces to provide an additional layer of protection and improve paint adhesion.

- Fill holes or gaps: For small holes or gaps, use an epoxy filler designed for metal surfaces. Shape and sand the filler to match the corrugated pattern.

Blending and Finishing

The final steps involve blending the repaired area with the surrounding siding:

- Color match: Obtain paint that matches the color of your existing corrugated steel siding panels. Consider using a paint specifically formulated for metal surfaces.

- Apply paint: Use a spray paint or brush to apply the paint evenly over the repaired area. Multiple thin coats often yield better results than a single thick coat.

- Blend edges: Feather the paint at the edges of the repaired area to create a seamless transition with the surrounding siding.

- Allow to cure: Let the paint dry completely before exposing the repaired area to moisture or touch.

- Apply clear coat (optional): For added protection, consider applying a clear coat over the painted area.

By following these steps, you can effectively repair and blend rusted areas on your corrugated steel siding panels, restoring both their appearance and protective qualities. Remember, corrugated steel siding panels from a reputable factory are designed for durability, but proper maintenance is key to maximizing their lifespan.

Preventive Measures and Long-Term Maintenance

While corrugated steel siding panels are known for their durability, implementing preventive measures and maintaining a regular maintenance schedule can significantly extend their lifespan and preserve their appearance.

Regular Inspections and Cleaning

Proactive maintenance is crucial for preventing rust and catching issues early:

- Conduct bi-annual inspections: Thoroughly examine your corrugated steel siding panels for signs of rust, damage, or wear at least twice a year.

- Clean regularly: Remove dirt, debris, and potential corrosive substances by washing your siding with mild soap and water at least once a year.

- Address issues promptly: Repair any scratches, dents, or areas of paint damage as soon as they're noticed to prevent rust formation.

- Check fasteners: Ensure all screws and fasteners are tight and replace any that show signs of corrosion.

Protective Coatings and Treatments

Enhance the rust resistance of your corrugated steel siding panels with protective measures:

- Apply clear coat: Consider applying a clear, protective sealant over your siding to provide an extra barrier against moisture and corrosive elements.

- Repainting: If the original paint is showing signs of wear, repainting your siding can restore its protective qualities and refresh its appearance.

- Zinc-rich primers: When repairing or repainting, use zinc-rich primers for added corrosion resistance.

- Rust inhibitors: Apply rust-inhibiting products to areas prone to moisture accumulation or in highly corrosive environments.

Environmental Considerations

Tailor your maintenance approach to your specific environment:

- Coastal areas: In salt-rich environments, more frequent cleaning and inspections may be necessary to combat accelerated corrosion.

- Industrial zones: If your building is located near industrial areas, consider more robust protective coatings to guard against corrosive pollutants.

- High humidity regions: In areas with high humidity, ensure proper ventilation and consider using dehumidifiers to reduce moisture exposure.

- Seasonal preparations: In regions with harsh winters, take extra precautions to protect your siding from snow, ice, and de-icing chemicals.

By implementing these preventive measures and maintaining a consistent maintenance routine, you can significantly reduce the likelihood of rust formation on your corrugated steel siding panels. This proactive approach not only preserves the aesthetic appeal of your building but also ensures that your siding continues to provide optimal protection and insulation for years to come. Remember, high-quality corrugated steel siding panels from a reputable factory are designed for longevity, but their performance is maximized through diligent care and maintenance.

Conclusion

Repairing and blending rusted corrugated steel siding panels is a manageable task that can significantly extend the life and appearance of your building's exterior. By understanding the causes of rust, following a systematic repair process, and implementing preventive measures, you can maintain the integrity and aesthetic appeal of your siding. Regular inspections, prompt repairs, and proactive maintenance are key to preserving the durability, weather resistance, and insulation properties that make corrugated steel siding panels a popular choice in construction.

Are you looking to upgrade your building's exterior with high-quality, durable corrugated steel siding panels? At Weifang Sandong Building Materials Co., Ltd., we specialize in manufacturing top-tier exterior cladding solutions. Our corrugated steel siding panels offer unmatched strength, versatility, and aesthetic appeal, suitable for a wide range of architectural styles. With customizable colors, lengths up to 30 feet, and optional insulation, our panels provide the perfect blend of form and function. Experience the difference that premium corrugated steel siding can make for your project. Contact us today at info@sdqsc.com to learn more about our products and how we can enhance your building's exterior.

FAQ

How long do corrugated steel siding panels typically last?

High-quality corrugated steel siding panels can last 40-70 years with proper maintenance.

Can I paint over rusted areas without removing the rust first?

It's not recommended. Removing rust and applying a rust converter ensures better adhesion and longevity of the repair.

Are corrugated steel siding panels energy efficient?

Yes, especially when combined with insulation. They provide excellent thermal regulation, reducing heating and cooling costs.

How often should I inspect my corrugated steel siding for rust?

Bi-annual inspections are recommended, with more frequent checks in harsh environments.

References

1. American Iron and Steel Institute. (2021). "Steel Siding: Durability and Maintenance."

2. National Association of Home Builders. (2022). "Exterior Cladding Materials: Longevity and Performance."

3. Journal of Building Engineering. (2020). "Corrosion Protection Strategies for Metal Building Components."

4. Environmental Protection Agency. (2023). "Best Practices for Sustainable Building Materials."

5. International Journal of Corrosion. (2021). "Advances in Rust Prevention for Steel Construction Materials."