Advantages of Fibreglass Sandwich Panels in Marine Applications

The unique properties of fibreglass sandwich panels make them ideally suited for use in marine and coastal construction projects. Their lightweight nature reduces structural loads while maintaining impressive strength and rigidity. This allows for easier transportation, handling, and installation compared to heavier alternatives like concrete or steel.

Fibreglass composite materials are naturally resistant to the corrosive effects of salt water, humidity, and a wide range of chemicals, making them exceptionally well-suited for use in demanding coastal environments. Unlike metals that rust or wood that decays, fibreglass retains its structural integrity even after prolonged exposure to aggressive conditions. This durability translates into lower maintenance demands and a much longer service life, reducing the need for costly replacements. In addition, the panels feature a non-porous surface that prevents water absorption, helping preserve both structural strength and thermal insulation performance over many years of reliable service.

Enhanced Durability and Weather Resistance

Marine-grade fibreglass sandwich panels are engineered to withstand prolonged exposure to UV radiation, temperature fluctuations, and impacts from wind-borne debris. The outer fibreglass skins serve as a strong, impact-resistant barrier that shields the core material from external forces such as wind-driven debris, heavy rains, and physical wear. This tough exterior not only resists cracking and abrasion but also provides long-term durability in highly corrosive marine environments. As a result, the panels maintain both structural integrity and visual appeal, ensuring coastal buildings remain safe, reliable, and aesthetically pleasing even after many years of harsh weather exposure.

Superior Insulation Performance

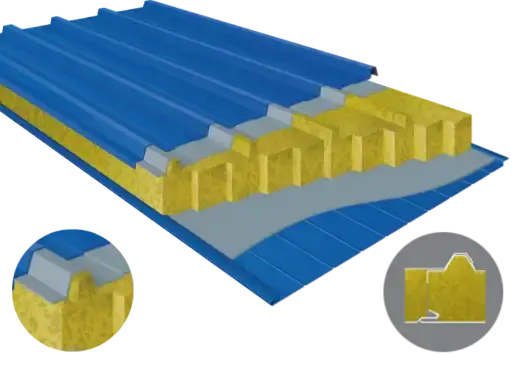

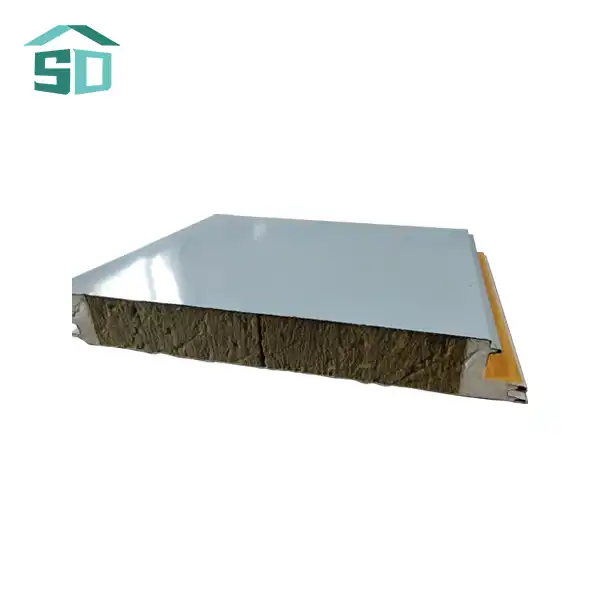

The core material of fibreglass sandwich panels, often made from foam or balsa wood, delivers exceptional thermal insulation, helping to stabilize indoor environments in marine structures. By reducing heat transfer, these panels lower the demand for heating and cooling systems, leading to energy savings and improved sustainability. Additionally, they provide valuable acoustic insulation, effectively reducing noise from crashing waves, strong winds, and nearby boat engines, thereby improving comfort and livability in coastal or offshore buildings.

Design Flexibility and Aesthetic Appeal

Fibreglass sandwich panels offer architects and designers tremendous versatility in creating visually striking marine and coastal buildings. These panels can be molded into complex shapes and curves, allowing for innovative architectural designs that complement seaside landscapes. The smooth surface of fibreglass panels readily accepts a wide range of finishes and colors, enabling customization to match specific aesthetic requirements.

Seamless Integration with Other Materials

Fibreglass sandwich panels can be easily integrated with other construction materials like glass, wood, or metal to create unique facade designs. Their lightweight nature allows for larger panel sizes, reducing the number of joints and creating a sleek, modern appearance. The panels can also be fabricated with embedded mounting points or reinforcements to simplify the installation of exterior cladding or decorative elements.

Customization Options

Manufacturers offer fibreglass sandwich panels in a variety of thicknesses, densities, and core materials to suit specific project requirements. Custom color matching and surface textures allow architects to achieve their desired aesthetic while maintaining the panel's functional benefits. Some panels can even incorporate decorative patterns or images directly into the fibreglass skin during manufacturing.

Installation and Maintenance Considerations

The lightweight nature of fibreglass sandwich panels simplifies the installation process, reducing construction time and labor costs. These panels can often be installed using standard tools and techniques, requiring minimal specialized equipment or training. The large panel sizes also mean fewer joints and fasteners, further streamlining the installation process.

Simplified Maintenance Procedures

Fibreglass sandwich panels require far less upkeep compared to conventional building materials typically exposed to the harsh coastal environment. Their smooth, non-porous surface naturally resists stains, mold, and salt deposits, ensuring a cleaner appearance over time. Routine cleaning is straightforward, often needing nothing more than mild detergent and fresh water. The inherent corrosion resistance of fibreglass also means there is no need for repainting, sealing, or protective coatings, dramatically lowering maintenance demands and costs throughout the building’s service life.

Repair and Replacement

In cases where damage does occur, fibreglass sandwich panels offer straightforward solutions that minimize disruption. Minor scratches, chips, or surface wear can often be addressed on-site with the use of specialized repair kits, restoring the panel’s integrity and appearance. For more serious damage, individual panels can be removed and replaced without disturbing adjacent sections, thanks to their modular design. This targeted repair capability not only shortens downtime but also reduces lifetime maintenance costs, making fibreglass panels a long-lasting and economical option.

Conclusion

Fibreglass sandwich panels offer a compelling solution for marine and coastal buildings, combining durability, performance, and design flexibility. Their unique properties address the challenges posed by harsh maritime environments while providing architects and builders with new possibilities for creating stunning seaside structures. As coastal development continues to grow, the adoption of innovative materials like fibreglass sandwich panels will play a crucial role in creating resilient, sustainable, and visually appealing marine architecture.

At Weifang Sandong Building Materials Co., Ltd., we are committed to providing high-quality fibreglass sandwich panels and other innovative building solutions for marine and coastal applications. Our advanced production facilities and rigorous quality control ensure that our products meet the highest standards of performance and durability. To learn more about how our fibreglass sandwich panels can benefit your next coastal construction project, please contact us at info@sdqsc.com.

FAQ

How do fibreglass sandwich panels compare to traditional materials for marine buildings?

Fibreglass sandwich panels offer superior corrosion resistance, lighter weight, and better insulation compared to materials like steel or concrete, making them ideal for marine environments.

Are fibreglass sandwich panels environmentally friendly?

Yes, these panels are often made with recycled materials and their durability reduces the need for frequent replacements, contributing to sustainability in construction.

Can fibreglass sandwich panels withstand extreme weather conditions?

Absolutely. These panels are engineered to resist UV radiation, temperature fluctuations, and impacts from wind-borne debris, making them highly suitable for coastal areas prone to severe weather.

References

1. Mouritz, A. P., & Gellert, E. (2000). Composite structures for marine applications. In Comprehensive Composite Materials (pp. 459-485). Elsevier.

2. Summerscales, J. (2014). Marine applications of advanced fibre-reinforced composites. Woodhead Publishing.

3. Greene, E. (2018). Structural design for the stage. Focal Press.

4. Hollaway, L. C. (2010). A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Construction and Building Materials, 24(12), 2419-2445.