- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the common finishes and colors available for PU panels?

PU insulated sandwich panels offer a wide range of finishes and colors to suit various architectural and aesthetic needs. The most common finishes include smooth, embossed, and textured surfaces, which can be customized to mimic materials like wood, stone, or metal. Color options are virtually limitless, with popular choices ranging from neutral tones like white, beige, and gray to bold hues such as red, blue, and green. Many manufacturers also offer custom color matching to ensure seamless integration with existing building designs. The versatility in finishes and colors makes PU insulated sandwich panels an excellent choice for both functional and visually appealing building exteriors.

Grasping PU Insulated Sandwich Panels and Their Finish Options

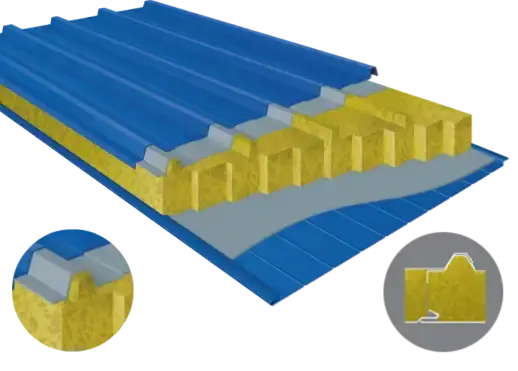

What are PU Insulated Sandwich Panels?

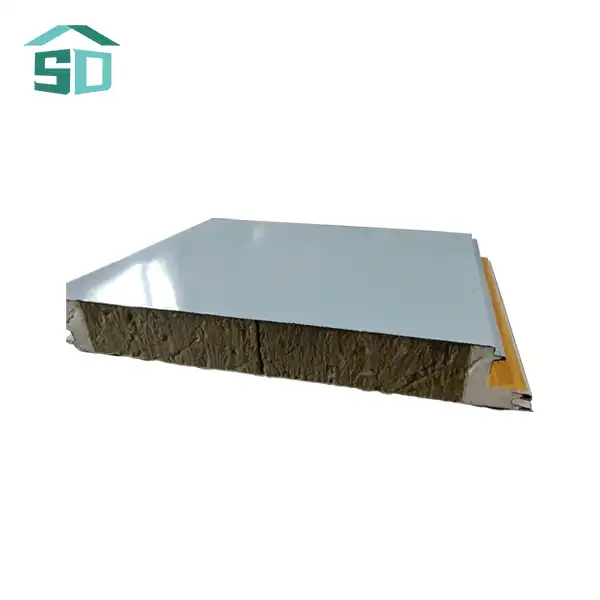

PU insulated sandwich panels are innovative building materials that have revolutionized the construction industry. These panels consist of three layers: two exterior metal facings and an inner core of polyurethane foam insulation. The combination of these materials creates a lightweight yet sturdy panel that offers excellent thermal insulation properties.

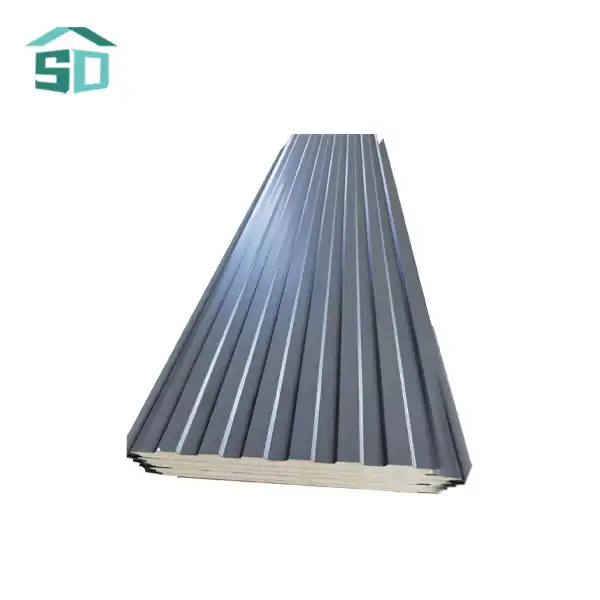

PU insulated sandwich panels are widely used in various construction applications, including walls, roofs, and ceilings of industrial, commercial, and residential buildings. Their popularity stems from their ability to provide superior insulation, energy efficiency, and ease of installation compared to traditional building materials.

The Importance of Finishes in PU Insulated Sandwich Panels

The finish of PU insulated sandwich panels plays a crucial role in both the aesthetic appeal and functional performance of a building. A well-chosen finish can enhance the overall appearance of a structure, protect the panels from environmental factors, and contribute to the longevity of the building envelope.

Finishes for PU insulated sandwich panels are not just about looks; they also serve practical purposes. They can improve the panel's resistance to corrosion, UV radiation, and chemical exposure. Additionally, certain finishes can enhance the panel's fire resistance properties, making them an essential consideration for building safety.

Common Finish Options for PU Insulated Sandwich Panels

PU insulated sandwich panels suppliers offer a variety of finish options to cater to different architectural requirements and personal preferences. Some of the most common finishes include:

- Smooth Finish: This is the most basic and widely used finish for PU insulated sandwich panels. It provides a clean, modern look and is easy to maintain.

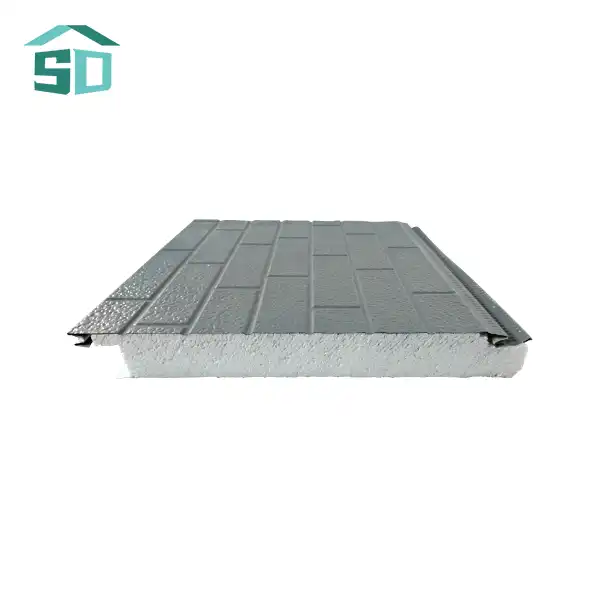

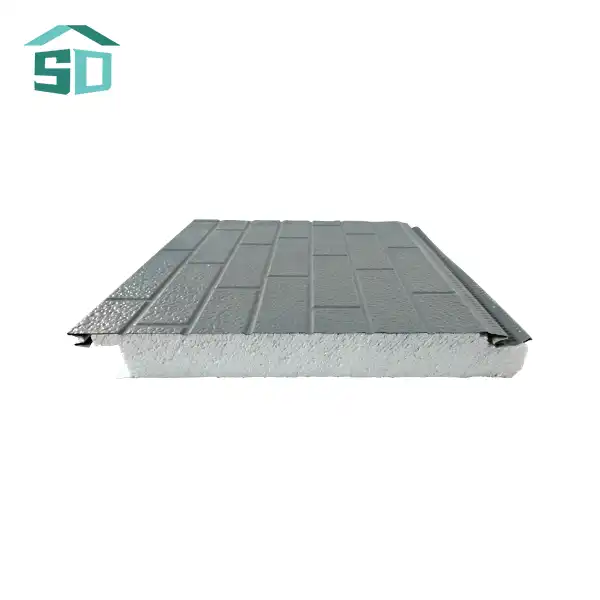

- Embossed Finish: This finish features a textured pattern pressed into the metal surface, adding depth and visual interest to the panels.

- Wood Grain Finish: This finish mimics the appearance of natural wood, offering the warmth of timber without the maintenance issues associated with real wood.

- Stucco Finish: This finish replicates the texture of traditional stucco, providing a classic, Mediterranean-inspired look.

- Metallic Finish: This finish gives panels a sleek, modern appearance, often used in contemporary architectural designs.

- Stone Finish: This finish imitates the look of natural stone, offering a robust and elegant appearance.

Each of these finishes can be further customized with various colors and sheen levels to achieve the desired aesthetic effect. The choice of finish can significantly impact the overall look and feel of a building, making it an essential consideration in the design process.

Exploring Color Options for PU Insulated Sandwich Panels

The Role of Color in Architectural Design

Color plays a pivotal role in architectural design, influencing not only the visual appeal of a building but also its perceived character and even its energy efficiency. When it comes to PU insulated sandwich panels, the color selection can dramatically affect the overall aesthetic of a structure, its integration with the surrounding environment, and its ability to reflect or absorb heat.

Architects and designers often use color strategically to achieve specific goals. For instance, lighter colors can make a building appear larger and more open, while darker hues can create a sense of intimacy and coziness. Moreover, color choices can reflect the purpose of a building, with vibrant colors often used for educational or recreational facilities, and more subdued tones for professional or industrial settings.

Standard Color Options for PU Insulated Sandwich Panels

PU insulated sandwich panels suppliers typically offer a wide range of standard colors to suit various architectural styles and preferences. These standard options often include:

- Neutral Tones: Colors like white, off-white, beige, and gray are popular choices for their versatility and timeless appeal.

- Earth Tones: Browns, tans, and terra cotta shades can help buildings blend with natural surroundings or create a warm, inviting atmosphere.

- Cool Colors: Blues and greens in various shades can evoke a sense of calm and are often used in healthcare or educational facilities.

- Warm Colors: Reds, oranges, and yellows can add energy and vibrancy to a building's exterior.

- Metallic Shades: Silver, bronze, and copper tones can lend a modern, industrial look to structures.

These standard color options are typically formulated to offer excellent UV resistance and color stability, ensuring that the building's appearance remains consistent over time. Many PU insulated sandwich panels suppliers also provide color charts or digital color selectors to help clients visualize different color options for their projects.

Custom Color Matching for PU Insulated Sandwich Panels

While standard color options cover a broad spectrum, sometimes a project requires a specific color that's not available in the standard range. In such cases, many PU insulated sandwich panels suppliers offer custom color matching services. This allows architects and building owners to achieve exactly the look they envision for their projects.

Custom color matching typically involves the following process:

1. The client provides a color sample or reference (e.g., a paint chip, fabric swatch, or color code).

2. The supplier's color specialists use advanced color matching technology to create a formula that closely matches the desired color.

3. A sample panel is produced with the custom color for the client's approval.

4. Once approved, the custom color is used in the production of the PU insulated sandwich panels for the project.

This level of customization ensures that PU insulated sandwich panels can meet even the most specific design requirements, allowing for seamless integration with existing structures or branding elements. However, it's worth noting that custom colors may have longer lead times and potentially higher costs compared to standard color options.

Factors Influencing Finish and Color Selection for PU Insulated Sandwich Panels

Environmental Considerations

When selecting finishes and colors for PU insulated sandwich panels, environmental factors play a crucial role. The local climate, exposure to sunlight, and proximity to corrosive elements (such as salt water in coastal areas) can all impact the performance and longevity of the panels.

For instance, in areas with high UV exposure, lighter colors and UV-resistant finishes are often preferred as they reflect more sunlight, reducing heat absorption and potentially improving the building's energy efficiency. In coastal regions, finishes with enhanced corrosion resistance are essential to protect the panels from salt spray and moisture.

Additionally, some finishes and colors can contribute to a building's environmental performance. Cool roof colors, which reflect more sunlight and absorb less heat, can help reduce the urban heat island effect and lower cooling costs in warm climates.

Building Function and Aesthetics

The intended use of a building and its desired aesthetic appeal significantly influence the choice of finishes and colors for PU insulated sandwich panels. Different types of buildings often have distinct visual requirements:

- Industrial Buildings: Often favor practical, low-maintenance finishes in neutral or metallic colors.

- Commercial Spaces: May opt for sleek, modern finishes and colors that align with brand identity.

- Educational Institutions: Might choose vibrant colors or finishes that create an engaging learning environment.

- Healthcare Facilities: Often prefer calming colors and easy-to-clean finishes.

- Residential Buildings: May select finishes and colors that complement the surrounding architecture and natural environment.

The architectural style of the building also plays a role. For example, a contemporary design might favor smooth, metallic finishes, while a more traditional structure could benefit from wood grain or stucco-like finishes.

Maintenance and Longevity

The ease of maintenance and long-term durability of PU insulated sandwich panels are important considerations when selecting finishes and colors. Some finishes are more resistant to dirt, staining, and fading, which can reduce maintenance requirements and preserve the building's appearance over time.

Smooth finishes, for instance, are generally easier to clean than heavily textured ones. However, textured finishes might be better at hiding minor scratches or dents. Similarly, lighter colors may show dirt more readily than darker shades, but they typically fade less noticeably over time.

When it comes to longevity, high-quality finishes with advanced coating technologies can significantly extend the life of PU insulated sandwich panels. These may include:

- Anti-graffiti coatings for easy cleaning in urban environments

- Self-cleaning finishes that use nanotechnology to repel dirt and water

- Anti-microbial finishes for healthcare or food processing facilities

- Highly durable finishes that resist chalking and fading

By considering these factors - environmental conditions, building function and aesthetics, and maintenance requirements - architects and building owners can make informed decisions about the finishes and colors for their PU insulated sandwich panels, ensuring both visual appeal and long-term performance.

Conclusion

The world of PU insulated sandwich panels offers a vast array of finishes and colors, providing architects and building owners with unprecedented flexibility in design. From smooth and embossed finishes to wood grain and metallic options, these panels can adapt to any architectural style or functional requirement. The color palette ranges from classic neutrals to vibrant hues, with custom color matching available for specific needs. When selecting finishes and colors, it's crucial to consider environmental factors, building function, aesthetic goals, and maintenance requirements to ensure optimal performance and longevity.

As a leading PU insulated sandwich panels supplier, Weifang Sandong Building Materials Co., Ltd. is committed to providing high-quality panels with a wide range of finish and color options. Our advanced production lines and strict quality control ensure that each panel meets the highest standards of durability and aesthetic appeal. Whether you're working on a residential complex, office building, or industrial facility, we have the expertise to help you select the perfect finish and color for your project. For more information about our PU insulated sandwich panels and other exterior cladding solutions, please contact us at info@sdqsc.com.

FAQ

Can PU insulated sandwich panels be painted after installation?

While it's possible to paint PU insulated sandwich panels after installation, it's generally not recommended. The factory-applied finishes are designed for optimal adhesion and durability. Painting on-site may void warranties and potentially compromise the panel's performance.

How do I clean PU insulated sandwich panels?

Most PU insulated sandwich panels can be cleaned with mild soap and water. Avoid abrasive cleaners or tools that could damage the finish. For specific cleaning instructions, consult the manufacturer's guidelines or contact us at info@sdqsc.com for advice.

Are there fire-resistant finish options for PU insulated sandwich panels?

Yes, many manufacturers offer fire-resistant coatings as an additional layer of protection. These specialized finishes can enhance the panel's fire performance, meeting stringent building code requirements.

References

1. Architectural Design Handbook: Color Theory in Building Design (2022)

2. Journal of Building Engineering: "Advances in Insulated Panel Technology" (2021)

3. Construction Materials Today: "Innovations in Building Envelope Solutions" (2023)

4. International Building Code (IBC): Fire Safety Requirements for Exterior Cladding (2021)

5. Energy Efficiency in Buildings: "Impact of Exterior Colors on Energy Consumption" (2022)