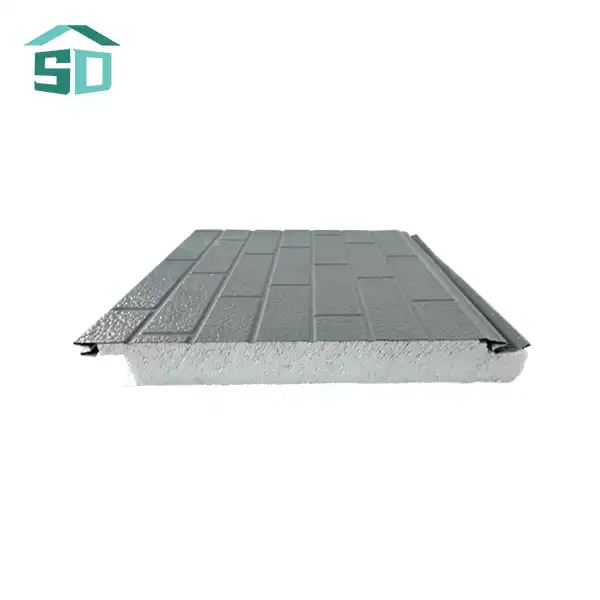

Proper Installation Techniques for Corrugated Sandwich Panels

Preparation and Planning

Before installing corrugated sandwich panels, thorough preparation and planning are crucial. This phase involves assessing the building structure, determining panel layout, and ensuring all necessary tools and materials are on hand. A corrugated sandwich panel manufacturer often provides detailed installation guides specific to their products, which should be carefully reviewed.

Key steps in the preparation phase include:

- Conducting a site survey to identify any potential challenges or obstructions

- Verifying that the supporting structure meets the required specifications

- Creating a detailed installation plan, including panel placement and fastening points

- Ensuring proper safety equipment and scaffolding are in place

Proper planning not only facilitates a smooth installation process but also helps prevent costly mistakes and ensures the longevity of the corrugated sandwich panel system.

Panel Handling and Storage

Correct handling and storage of corrugated sandwich panels are vital to maintain their integrity and appearance. Improper handling can lead to damage, compromising the panel's performance and aesthetic appeal. Here are some best practices for handling and storing corrugated sandwich panels:

- Store panels in a dry, well-ventilated area to prevent moisture accumulation

- Keep panels off the ground using pallets or blocks to avoid water damage

- Use appropriate lifting equipment, such as vacuum lifters or panel lifters, to move panels safely

- Avoid dragging panels across each other or rough surfaces to prevent scratches

- Stack panels vertically when possible to minimize weight on lower panels

By following these guidelines, installers can ensure that corrugated sandwich panels remain in pristine condition until they are ready for installation.

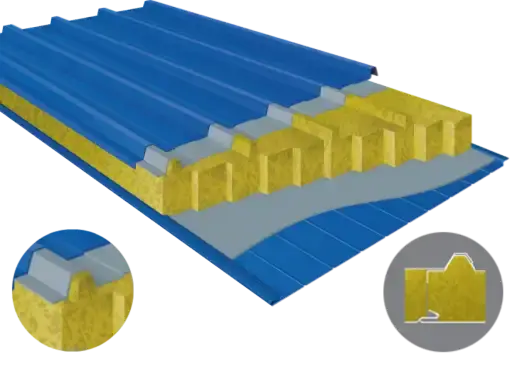

Installation Process

The installation process for corrugated sandwich panels requires precision and attention to detail. While specific steps may vary depending on the manufacturer's guidelines and project requirements, the general process typically includes the following:

1. Begin installation from the bottom of the wall, working upwards

2. Apply sealant or gaskets to joints and connections to ensure weathertightness

3. Secure panels using appropriate fasteners, following the manufacturer's recommendations for spacing and torque

4. Install flashing and trim elements to protect vulnerable areas and enhance aesthetics

5. Cut panels as needed using specialized tools to maintain clean edges and avoid damaging the core material

Throughout the installation process, it's crucial to maintain proper alignment and ensure that each corrugated sandwich panel is securely fastened. This attention to detail not only enhances the visual appeal of the finished project but also maximizes the panels' performance in terms of insulation and weather resistance.

Recycling Practices for Corrugated Sandwich Panels

End-of-Life Considerations

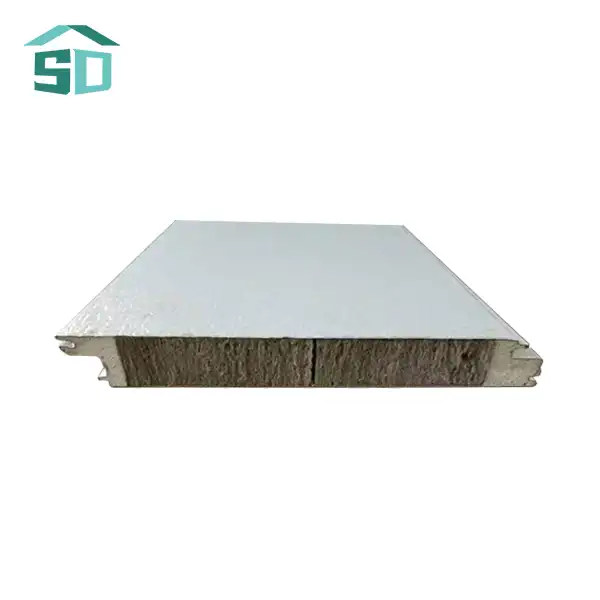

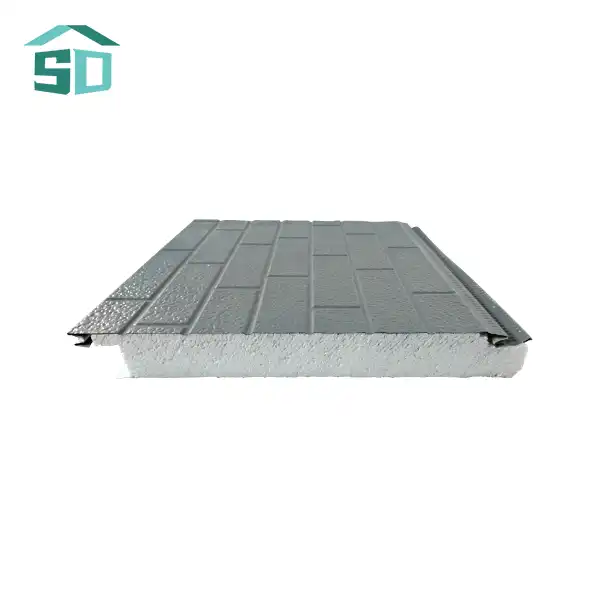

As buildings reach the end of their lifespan or undergo renovations, the question of what to do with used corrugated sandwich panels arises. Responsible end-of-life management is essential for minimizing environmental impact and conserving resources. When considering the disposal or recycling of corrugated sandwich panels, several factors come into play:

- The composition of the panel, including the type of metal facing and core material

- The condition of the panels and any potential contamination

- Local recycling facilities and their capabilities

- Regulations governing the disposal of construction materials

By carefully evaluating these factors, building owners and contractors can make informed decisions about the most appropriate end-of-life strategy for their corrugated sandwich panels.

Disassembly and Sorting

The first step in recycling corrugated sandwich panels is proper disassembly and sorting. This process involves separating the different components of the panel to facilitate recycling. Here's an overview of the disassembly and sorting process:

1. Remove any attachments or accessories from the panels

2. Separate the metal facings from the insulating core

3. Sort the metal facings by type (e.g., steel, aluminum)

4. Categorize the core material based on its composition (e.g., polyurethane, mineral wool)

Proper disassembly and sorting not only make the recycling process more efficient but also increase the likelihood that materials can be effectively recycled or repurposed.

Recycling Methods and Technologies

The recycling of corrugated sandwich panels involves various methods and technologies, depending on the materials involved. Here's an overview of some common recycling approaches:

- Metal Recycling: The metal facings of corrugated sandwich panels can typically be recycled through standard metal recycling processes. This may involve shredding, melting, and reforming the metal into new products.

- Insulation Core Recycling: Depending on the type of insulation used, different recycling methods may be employed:

- Polyurethane foam can be recycled through chemical processes or used as a fuel source in cement kilns

- Mineral wool can be reprocessed into new insulation products or used as a raw material in other industries

- Mechanical Recycling: Some facilities use mechanical processes to separate and recycle the different components of corrugated sandwich panels

- Energy Recovery: In cases where direct recycling is not feasible, panels may be used for energy recovery in waste-to-energy facilities

As recycling technologies continue to advance, more efficient and environmentally friendly methods for recycling corrugated sandwich panels are being developed. This ongoing innovation contributes to the overall sustainability of these building materials.

Best Practices for Sustainable Use of Corrugated Sandwich Panels

Design for Disassembly

Incorporating design for disassembly principles when using corrugated sandwich panels can significantly facilitate future recycling efforts. This approach involves designing buildings and panel systems with eventual deconstruction in mind. Key considerations include:

- Using standardized panel sizes to improve reusability

- Opting for mechanical fastening methods over adhesives when possible

- Incorporating easily removable trim and flashing components

- Documenting the building's construction details for future reference

By adopting these practices, architects and builders can ensure that corrugated sandwich panels can be more easily recycled or repurposed at the end of their initial use.

Maintenance and Longevity

Proper maintenance of corrugated sandwich panels is crucial for maximizing their lifespan and delaying the need for replacement. Regular maintenance not only preserves the panels' appearance but also ensures their continued performance. Best practices for maintaining corrugated sandwich panels include:

- Regular inspections to identify and address any damage or wear

- Cleaning panels according to manufacturer recommendations to prevent buildup of dirt or contaminants

- Promptly repairing any minor damage to prevent more extensive issues

- Reapplying protective coatings as needed to maintain weather resistance

By implementing a comprehensive maintenance program, building owners can extend the useful life of their corrugated sandwich panels, reducing the frequency of replacement and associated environmental impacts.

Choosing Sustainable Materials

When selecting corrugated sandwich panels for a project, considering the sustainability of the materials used can have a significant impact on the overall environmental footprint. Factors to consider include:

- Recycled content: Opting for panels with high recycled content in their metal facings

- Recyclability: Choosing panels with easily recyclable components

- Environmental certifications: Looking for panels that have received third-party sustainability certifications

- Local sourcing: Selecting panels manufactured locally to reduce transportation emissions

By prioritizing sustainable materials, builders and architects can contribute to a more circular economy in the construction industry while still benefiting from the performance advantages of corrugated sandwich panels.

Conclusion

Proper installation and responsible recycling practices are essential for maximizing the benefits of corrugated sandwich panels while minimizing their environmental impact. By following best practices for installation, including thorough preparation, careful handling, and precise execution, builders can ensure optimal performance and longevity of these versatile building materials. Equally important are the end-of-life considerations, where proper disassembly, sorting, and recycling techniques play a crucial role in conserving resources and reducing waste. As the construction industry continues to evolve, embracing sustainable design principles and innovative recycling technologies will further enhance the eco-friendliness of corrugated sandwich panels.

For those seeking high-quality corrugated sandwich panels and expert guidance on their installation and sustainable use, Weifang Sandong Building Materials Co., Ltd. stands ready to assist. As a leading corrugated sandwich panel manufacturer, we are committed to providing superior products and unparalleled service to enhance your construction projects. To learn more about our exterior cladding and facade solutions, please contact us at info@sdqsc.com.

FAQ

What are the main advantages of using corrugated sandwich panels in construction?

Corrugated sandwich panels offer excellent thermal insulation, structural strength, and quick installation. They are lightweight, durable, and provide a sleek, modern aesthetic to buildings.

How long do corrugated sandwich panels typically last?

With proper installation and maintenance, corrugated sandwich panels can last 30-50 years, depending on the environment and usage conditions.

Are corrugated sandwich panels environmentally friendly?

Yes, when properly recycled and chosen with sustainability in mind, corrugated sandwich panels can be an environmentally friendly building option due to their energy efficiency and potential for recycling.

References

1. European Panel Federation. (2021). "Recycling of Sandwich Panels."

2. International Association of Certified Home Inspectors. (2022). "Insulated Metal Panels."

3. Metal Construction Association. (2020). "Insulated Metal Panels."

4. U.S. Green Building Council. (2021). "LEED v4 for Building Design and Construction."

5. World Steel Association. (2022). "Steel in the Circular Economy."