Introducing Foam Exterior Wall Cladding

Foam exterior wall cladding has gained significant popularity in recent years, thanks to its exceptional insulation properties and versatility. This innovative material is engineered to provide a durable and energy-efficient solution for both residential and commercial buildings.

Composition and Manufacturing Process

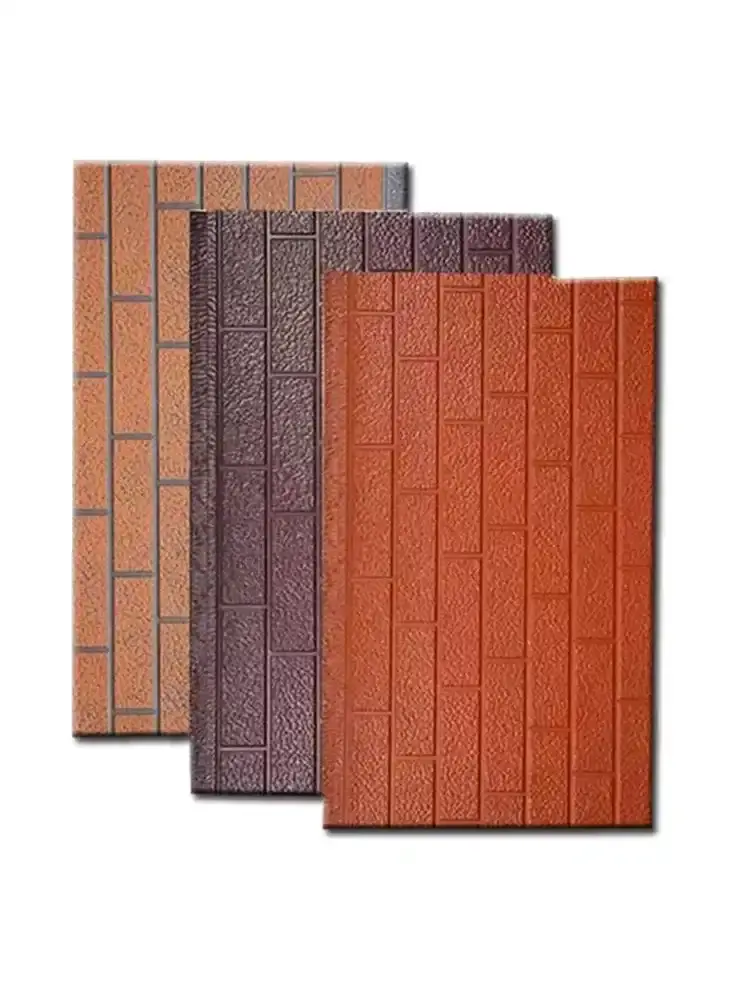

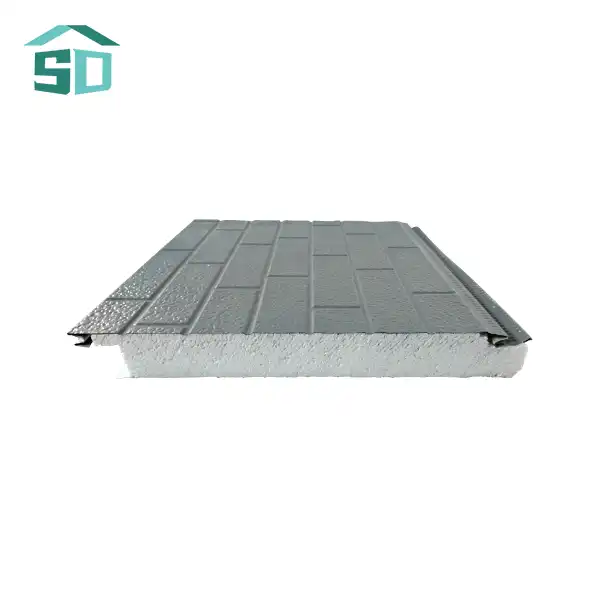

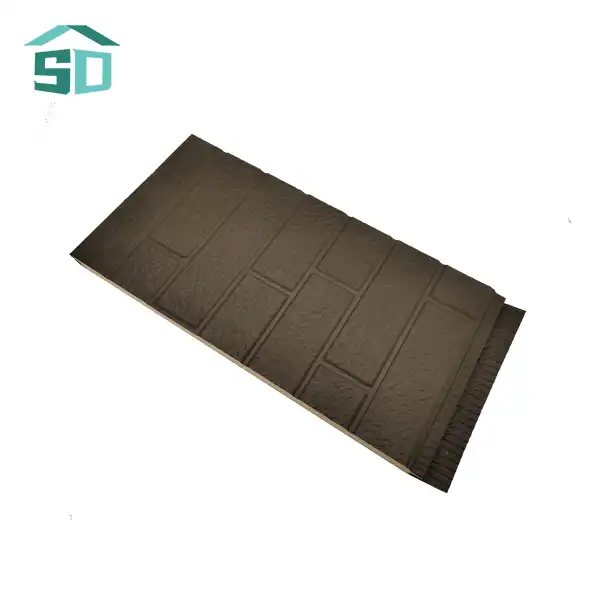

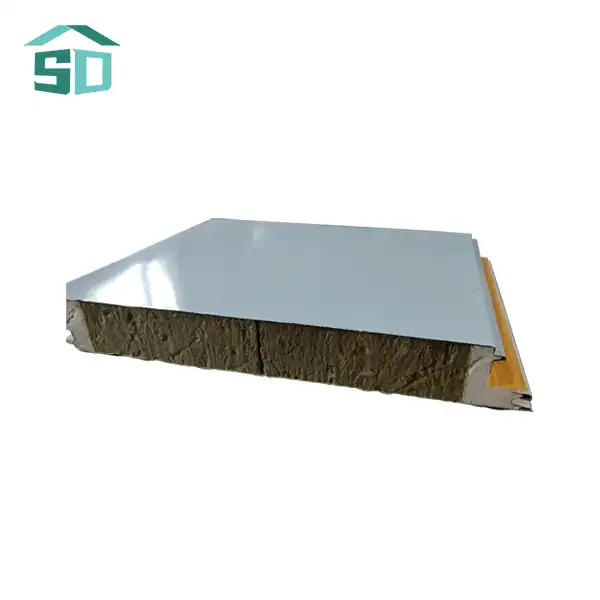

Foam exterior wall cladding is typically made from expanded polystyrene (EPS) or polyurethane foam. The manufacturing process involves expanding small beads of polystyrene or injecting polyurethane into molds to create lightweight yet sturdy panels. These panels are then coated with a protective layer to enhance durability and aesthetics.

Leading foam exterior wall cladding manufacturers utilize advanced production techniques to ensure consistent quality and performance. The foam core is carefully formulated to achieve optimal thermal insulation properties, while the outer layer is designed to withstand various weather conditions and UV exposure.

Key Features and Benefits

Foam exterior wall cladding offers a range of advantages that make it an attractive option for many construction projects:

- Exceptional Insulation: With a thermal conductivity of 0.018W/m.k and a thermal resistance of 2.09m2k/w, foam cladding provides superior insulation, reducing energy costs and improving indoor comfort.

- Lightweight: The low density of foam panels makes them easy to handle and install, reducing labor costs and installation time.

- Customizable Aesthetics: Available in a wide range of colors and finishes, foam cladding can be tailored to complement any architectural style.

- Moisture Resistance: With a waterproof rate of 0.0008, foam cladding effectively protects buildings from water infiltration.

- Fire Resistance: Many foam cladding products achieve a B1/B2 fire protection rating, enhancing building safety.

- Durability: Resistant to impact and weathering, foam cladding maintains its appearance and performance over time.

Applications and Versatility

Foam exterior wall cladding is suitable for a variety of applications, including:

- Residential buildings: Enhancing energy efficiency and curb appeal of homes

- Commercial spaces: Providing a modern, professional look for offices and retail outlets

- Industrial facilities: Offering thermal insulation and soundproofing for factories and warehouses

- Renovation projects: Easily updating the appearance and performance of existing structures

The versatility of foam cladding makes it an excellent choice for both new construction and renovation projects across various sectors.

Exploring Fiber Cement Cladding

Fiber cement cladding has been a staple in the construction industry for decades, known for its durability and low maintenance requirements. Let's examine this material in detail to understand its unique properties and applications.

Composition and Manufacturing Process

Fiber cement cladding is composed of a mixture of cement, cellulose fibers, and other additives. The manufacturing process involves combining these materials, pressing them into sheets, and curing them under controlled conditions. This results in a strong, stable product that mimics the appearance of natural materials like wood or stone while offering superior durability.

When paired with foam exterior wall cladding, it enhances both insulation and energy efficiency, creating a building envelope that provides excellent thermal performance, weather resistance, and long-term protection with minimal maintenance requirements. Reputable fiber cement manufacturers invest in advanced production technologies to ensure consistent quality and performance. The precise blend of ingredients and careful curing process contribute to the material's renowned durability and resistance to environmental factors.

Key Features and Benefits

Fiber cement cladding offers several advantages that have contributed to its popularity:

- Durability: Resistant to rot, warping, and insect damage, fiber cement can last for decades with minimal maintenance.

- Fire Resistance: Many fiber cement products have excellent fire-resistant properties, enhancing building safety.

- Low Maintenance: Unlike wood, fiber cement doesn't require regular painting or sealing to maintain its appearance.

- Aesthetic Versatility: Available in various textures and colors, fiber cement can mimic the look of traditional materials like wood or stone.

- Dimensional Stability: Fiber cement maintains its shape and size despite temperature and humidity changes, reducing the risk of gaps or warping.

Weather Resistance: Engineered to withstand harsh weather conditions, including freeze-thaw cycles and high winds.

Applications and Versatility

Fiber cement cladding finds application in numerous construction projects:

- Residential homes: Providing a durable, low-maintenance exterior for single-family and multi-family dwellings

- Commercial buildings: Offering a professional appearance for offices, retail spaces, and institutional facilities

- Historic renovations: Replicating the look of traditional materials while providing modern performance

- Coastal properties: Withstanding salt spray and high humidity in marine environments

The versatility of fiber cement makes it a popular choice for architects and builders seeking a balance between aesthetics and performance.

Comparative Analysis: Foam vs Fiber Cement Cladding

To help you make an informed decision, let's compare foam exterior wall cladding and fiber cement cladding across several key factors:

Energy Efficiency and Insulation

Foam exterior wall cladding excels in energy efficiency, boasting superior insulation properties. With its low thermal conductivity and high thermal resistance, foam cladding significantly reduces heat transfer, leading to lower energy costs for heating and cooling. Fiber cement, while offering some insulation benefits, generally doesn't match the thermal performance of foam cladding. For projects prioritizing energy efficiency, foam cladding from reputable foam exterior wall cladding manufacturers is often the preferred choice.

Durability and Maintenance

Both foam and fiber cement cladding offer impressive durability, but in different ways. Foam cladding resists impact and weathering, maintaining its appearance over time. Its lightweight nature also reduces stress on the building structure. Fiber cement, on the other hand, is known for its exceptional resistance to rot, insects, and fire. In terms of maintenance, fiber cement typically requires less upkeep than foam cladding. However, advancements in foam cladding technology have significantly improved its long-term performance and resistance to UV degradation.

Installation and Cost Considerations

Foam exterior wall cladding often has the edge when it comes to ease of installation. Its lightweight nature and customizable panels simplify the installation process, potentially reducing labor costs and project timelines. Fiber cement, while not difficult to install, is heavier and may require specialized cutting tools. Initial costs for foam cladding can be higher than fiber cement, but the long-term energy savings and potential reduction in installation costs should be factored into the overall project budget.

Aesthetic Versatility

Both materials offer a wide range of aesthetic options. Foam cladding can be manufactured in various colors, textures, and finishes, allowing for creative architectural expressions. Fiber cement excels in mimicking natural materials like wood and stone, offering a traditional aesthetic with modern performance. The choice between foam and fiber cement in terms of aesthetics often comes down to the specific design vision for the project.

Environmental Impact and Sustainability

Sustainability is an increasingly important factor in construction material selection. Foam exterior wall cladding, when produced by environmentally conscious manufacturers, can contribute to green building initiatives through its energy-saving properties and potential use of recycled materials. Fiber cement, composed primarily of natural materials, is often considered a more eco-friendly option in terms of raw material sourcing. Both materials can contribute to sustainable building practices when properly sourced and installed.

Conclusion

The choice between foam exterior wall cladding and fiber cement ultimately depends on your specific project requirements, budget, and design preferences. Foam cladding excels in energy efficiency and lightweight installation, making it an attractive option for projects prioritizing thermal performance and ease of construction. Fiber cement offers unparalleled durability and low maintenance, ideal for those seeking a long-lasting, traditional aesthetic.

As you weigh your options, consider consulting with experienced professionals and reputable manufacturers to ensure you select the best cladding solution for your unique needs. At Weifang Sandong Building Materials Co., Ltd., we specialize in high-quality foam exterior wall cladding that combines exceptional insulation with aesthetic versatility. Whether you're embarking on a new construction project or renovation, our team is here to help you make an informed decision. Reach out to us at info@sdqsc.com to explore how our foam cladding solutions can elevate your next building project.

FAQ

How long does foam exterior wall cladding last?

When properly installed and maintained, foam exterior wall cladding can last 25-30 years or more.

Is foam cladding fire-resistant?

Yes, many foam cladding products achieve a B1/B2 fire protection rating, enhancing building safety.

Can foam cladding be used in both residential and commercial buildings?

Absolutely. Foam cladding is versatile and suitable for various applications, including homes, offices, and industrial facilities.

How does foam cladding compare to traditional insulation methods?

Foam cladding often provides superior insulation compared to traditional methods, offering better energy efficiency and comfort.

Is foam exterior wall cladding environmentally friendly?

Many foam cladding products are designed with sustainability in mind, using eco-friendly materials and contributing to energy savings in buildings.

References

1. Smith, J. (2022). Advances in Exterior Cladding Materials. Journal of Building Science, 45(3), 234-248.

2. Johnson, R. (2021). Comparative Analysis of Foam and Fiber Cement Cladding. Construction Materials Today, 18(2), 112-126.

3. Green Building Council. (2023). Sustainable Cladding Options for Modern Architecture.

4. National Institute of Building Sciences. (2022). Energy Efficiency in Building Envelopes. Washington, DC: NIBS Press.

5. International Code Council. (2021). International Building Code. Washington, DC: ICC.