The Science Behind Green Thermal Insulation Panels

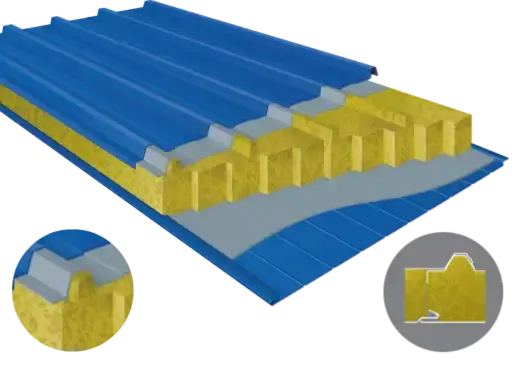

Green thermal insulation panels represent a significant leap forward in building technology. These panels leverage advanced materials science to create highly efficient barriers against heat transfer. At their core, green thermal insulation panels utilize materials with low thermal conductivity, effectively trapping air and preventing the movement of heat through walls, roofs, and floors.

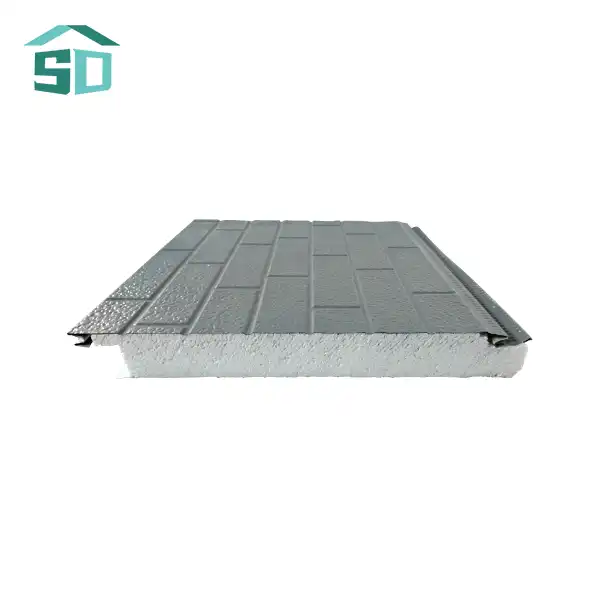

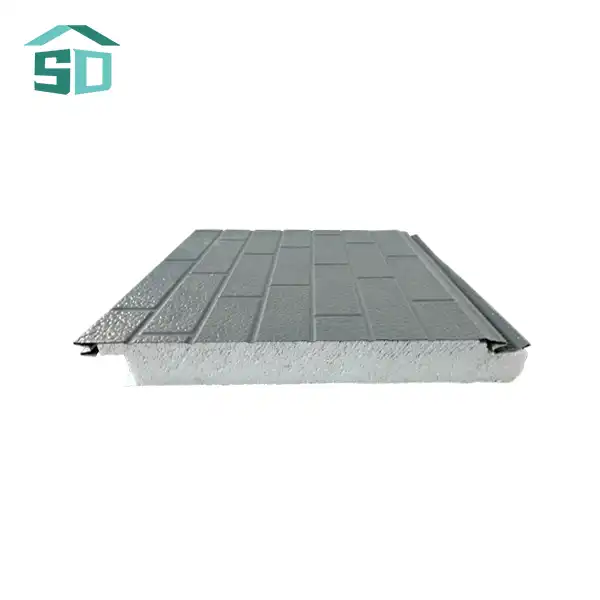

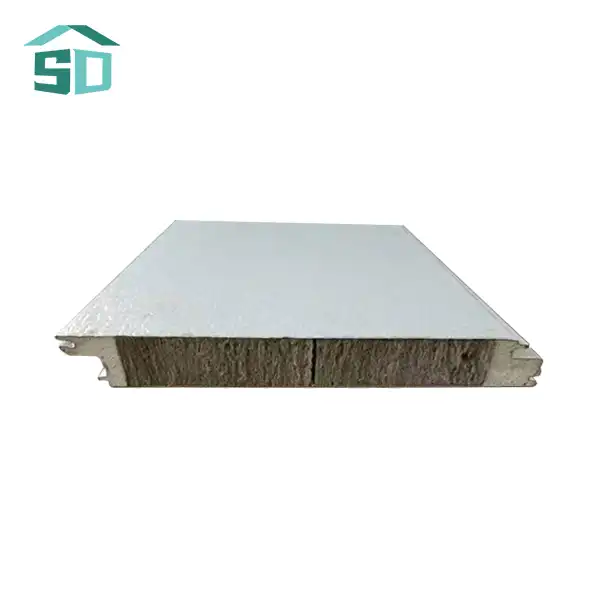

The insulation layer in these panels typically consists of materials such as polyurethane, polystyrene, rock wool, or glass wool. Each of these materials has unique properties that contribute to the overall performance of the panel. For instance, polyurethane offers excellent insulation properties with a relatively thin layer, making it ideal for applications where space is at a premium. Rock wool, on the other hand, provides superior fire resistance and sound insulation in addition to its thermal properties.

Advanced Manufacturing Techniques

The production of green thermal insulation panels involves sophisticated manufacturing processes that ensure consistency and quality. State-of-the-art production lines employ precise control over the mixing and curing of insulation materials, resulting in panels with uniform density and thermal properties. This precision manufacturing contributes to the panels' ability to maintain their insulation performance over extended periods, even under varying environmental conditions.

Thermal Performance Metrics

The effectiveness of green thermal insulation panels is often measured using R-value, which indicates the material's resistance to heat flow. Higher R-values signify better insulation properties. Green thermal insulation panels typically boast higher R-values per inch of thickness compared to traditional insulation materials, allowing for excellent thermal performance without excessive wall thickness.

Another crucial metric is the U-value, which measures heat transfer through a building element. Lower U-values indicate better insulation. Green thermal insulation panels are designed to achieve impressively low U-values, contributing to significant energy savings in both residential and commercial buildings.

Environmental Benefits of Green Thermal Insulation Panels

The adoption of green thermal insulation panels offers a multitude of environmental benefits, positioning them as a cornerstone of sustainable construction practices. These panels play a crucial role in reducing the overall environmental impact of buildings, which account for a significant portion of global energy consumption and greenhouse gas emissions.

One of the primary environmental advantages of green thermal insulation panels is their ability to dramatically reduce energy consumption for heating and cooling. By creating a more effective thermal barrier, these panels minimize the need for artificial climate control, leading to lower energy usage and, consequently, reduced carbon emissions. This energy efficiency translates directly into a smaller carbon footprint for buildings equipped with these panels.

Sustainable Materials and Production

Many green thermal insulation panels are manufactured using recycled or renewable materials, further enhancing their environmental credentials. For instance, some panels incorporate recycled plastics or agricultural by-products in their insulation layers, diverting these materials from landfills and giving them a new, productive life. This approach not only reduces waste but also decreases the demand for virgin raw materials, conserving natural resources.

The production processes for these panels are often optimized for energy efficiency and minimal waste generation. Manufacturers of green thermal insulation panels frequently implement closed-loop systems that recycle production scraps and employ energy-efficient machinery, reducing the overall environmental impact of the manufacturing process.

Long-Term Environmental Impact

The durability and longevity of green thermal insulation panels contribute to their positive environmental impact over time. These panels are designed to maintain their insulation properties for decades, reducing the need for frequent replacements and the associated resource consumption. Additionally, at the end of their life cycle, many green thermal insulation panels can be recycled or repurposed, further minimizing their environmental footprint.

Practical Applications and Installation Considerations

Green thermal insulation panels offer versatile solutions for a wide range of building types and applications. Their adaptability makes them suitable for both new construction projects and retrofitting existing structures, providing opportunities to improve energy efficiency across diverse architectural styles and building ages.

In residential applications, green thermal insulation panels can be used to insulate exterior walls, roofs, and even floors. They are particularly effective in creating a continuous insulation layer that minimizes thermal bridging - areas where heat can easily transfer through the building envelope. This comprehensive insulation approach results in more consistent indoor temperatures and reduced energy bills for homeowners.

Commercial and Industrial Applications

The benefits of green thermal insulation panels extend well beyond residential use. In commercial and industrial settings, these panels play a crucial role in maintaining optimal temperatures in office buildings, warehouses, and manufacturing facilities. The superior insulation properties of these panels can lead to significant energy savings in large-scale structures, where heating and cooling costs can be substantial.

Green thermal insulation panels are also invaluable in specialized applications such as cold storage facilities, where maintaining consistent low temperatures is critical. The panels' ability to provide excellent insulation with minimal thickness allows for maximized storage space while ensuring energy-efficient operation.

Installation Considerations

Proper installation is key to maximizing the performance of green thermal insulation panels. The installation process typically involves several critical steps to ensure optimal thermal performance and longevity:

- Surface Preparation: The substrate must be clean, dry, and free from any debris or irregularities that could compromise the panel's adhesion or create gaps in the insulation layer.

- Precise Measurement and Cutting: Accurate measurements and precise cutting of panels are essential to ensure a snug fit and minimize thermal bridges at joints and edges.

- Secure Fastening: Panels must be securely fastened to the structure using appropriate methods, which may include mechanical fasteners, adhesives, or a combination of both, depending on the specific panel type and application.

- Sealing Joints and Penetrations: Special attention must be given to sealing all joints between panels and around any penetrations (such as windows, doors, or utilities) to maintain the integrity of the thermal barrier.

- Weather Barrier Integration: In exterior applications, proper integration with the building's weather barrier system is crucial to prevent moisture intrusion while maintaining thermal performance.

Professional installation by trained technicians is often recommended to ensure that green thermal insulation panels are installed correctly, maximizing their energy-saving potential and longevity.

Conclusion

Green thermal insulation panels represent a significant advancement in building technology, offering a powerful tool in the fight against climate change. By providing superior insulation properties, these panels dramatically reduce energy consumption and carbon emissions associated with heating and cooling buildings. Their versatility, durability, and eco-friendly composition make them an ideal choice for a wide range of applications, from residential homes to large commercial structures. As we continue to seek ways to minimize our environmental impact, green thermal insulation panels stand out as a practical and effective solution for creating more sustainable, energy-efficient buildings.

Ready to transform your building into an energy-efficient masterpiece? Explore our range of customizable green thermal insulation panels at Weifang Sandong Building Materials Co., Ltd. Our panels combine superior insulation with aesthetic appeal, offering a perfect blend of functionality and style. Whether you're renovating or starting a new construction project, our expert team is here to help you choose the ideal solution for your needs. Contact us today at info@sdqsc.com to learn how our green thermal insulation panels can help you cut your carbon footprint while enhancing your building's comfort and value.

FAQs

What makes green thermal insulation panels environmentally friendly?

Green thermal insulation panels are eco-friendly due to their energy-saving properties, use of recycled or renewable materials, and contribution to reducing a building's carbon footprint.

How do green thermal insulation panels compare to traditional insulation methods?

These panels typically offer superior insulation with less thickness, better durability, and often include additional benefits like fire resistance and sound insulation.

Can green thermal insulation panels be used in both new construction and renovations?

Yes, they are versatile and can be effectively used in both new builds and retrofitting existing structures.

What is the typical lifespan of green thermal insulation panels?

When properly installed and maintained, these panels can last for several decades, providing long-term energy savings and environmental benefits.

References

1. U.S. Department of Energy. (2022). Insulation Materials.

2. International Energy Agency. (2021). Buildings: A source of enormous untapped efficiency potential. IEA.

3. Environmental Protection Agency. (2023). Green Building. EPA.

4. World Green Building Council. (2022). The Net Zero Carbon Buildings Commitment. WorldGBC.