Comprehending Aluminum Foam Sandwich Panels: Composition and Properties

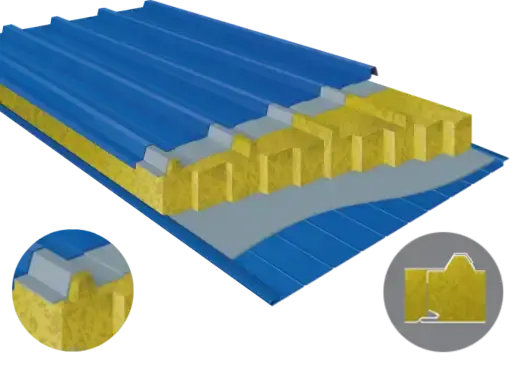

The Structure of Aluminum Foam Sandwich Panels

Aluminum foam sandwich panels are sophisticated composite materials that consist of three primary layers. The core is made of aluminum foam, a cellular structure of aluminum with a high porosity. This core is sandwiched between two thin, solid aluminum face sheets. The unique structure of aluminum foam sandwich panels provides them with exceptional properties that make them suitable for a wide range of applications.

The aluminum foam core is created through a specialized manufacturing process that involves introducing gas bubbles into molten aluminum. As the aluminum solidifies, these bubbles form a network of interconnected cells, resulting in a lightweight yet rigid structure. This cellular structure is key to the panel's ability to absorb energy, reduce weight, and provide thermal insulation.

Key Properties of Aluminum Foam Sandwich Panels

Aluminum foam sandwich panels boast an impressive array of properties that set them apart from traditional building materials:

- Lightweight: The cellular structure of the foam core significantly reduces the overall weight of the panel without compromising its strength.

- High Strength-to-Weight Ratio: Despite their low density, these panels offer excellent mechanical strength, making them ideal for load-bearing applications.

- Thermal Insulation: The air-filled cells in the foam core provide superior thermal insulation, helping to regulate temperature in buildings and vehicles.

- Sound Dampening: The porous structure of the foam effectively absorbs sound waves, reducing noise transmission.

- Energy Absorption: Aluminum foam can absorb significant amounts of kinetic energy, making it valuable in impact protection applications.

- Fire Resistance: The aluminum foam core has inherent fire-resistant properties, enhancing the safety of structures.

- Recyclability: As they are primarily composed of aluminum, these panels are highly recyclable, aligning with sustainable construction practices.

These properties make aluminum foam sandwich panels a versatile solution for various industries, from construction to transportation. The unique combination of lightweight design and robust performance characteristics has led to their increasing adoption in innovative applications across multiple sectors.

Best Applications of Aluminum Foam Sandwich Panels in Various Industries

Aerospace and Aviation

In the aerospace industry, where weight reduction is crucial for fuel efficiency and performance, aluminum foam sandwich panels have found significant applications. These panels are used in aircraft interiors, flooring, and structural components. Their ability to dampen vibrations and absorb sound makes them ideal for creating quieter cabins, enhancing passenger comfort. Additionally, their fire-resistant properties contribute to improved safety standards in aircraft design.

Satellite manufacturers also leverage the benefits of aluminum foam sandwich panels. The panels' high strength-to-weight ratio allows for the construction of lightweight yet durable satellite structures that can withstand the harsh conditions of space while minimizing launch costs associated with heavier materials.

Automotive Engineering

The automotive sector has embraced aluminum foam sandwich panels as a solution to reduce vehicle weight without compromising safety. These panels are increasingly used in body panels, hoods, and structural reinforcements. Their energy-absorbing properties make them excellent for creating crumple zones that protect passengers during collisions.

In electric vehicles, where battery weight is a significant concern, aluminum foam sandwich panels help offset the added weight of battery packs. This application allows for extended driving ranges and improved overall vehicle performance. Moreover, the thermal insulation properties of these panels contribute to better temperature management in electric vehicle battery compartments, enhancing battery life and efficiency.

Architecture and Construction

Architects and builders are incorporating aluminum foam sandwich panels into modern building designs for their aesthetic appeal and functional benefits. These panels are used in facade systems, offering a sleek, contemporary look while providing excellent thermal insulation. This insulation property helps in reducing heating and cooling costs, contributing to the energy efficiency of buildings.

In large-scale structures like stadiums and exhibition halls, aluminum foam sandwich panels are used for roofing and wall cladding. Their lightweight nature reduces the load on the building's structure, allowing for more flexible and innovative designs. The sound-dampening qualities of these panels also make them suitable for creating acoustically optimized spaces in auditoriums and concert halls.

Marine Applications

The marine industry benefits from the corrosion-resistant properties of aluminum foam sandwich panels. These panels are used in shipbuilding for decking, bulkheads, and superstructures. Their lightweight nature contributes to improved fuel efficiency and increased payload capacity in vessels. The panels' ability to absorb vibrations also enhances comfort for passengers and crew members.

In offshore platforms and structures, aluminum foam sandwich panels provide a durable and lightweight solution for flooring and wall systems. Their fire-resistant properties are particularly valuable in these high-risk environments, contributing to enhanced safety measures.

Retrofit Uses of Aluminum Foam Sandwich Panels in Existing Structures

Enhancing Energy Efficiency in Buildings

One of the most significant retrofit applications of aluminum foam sandwich panels is in improving the energy efficiency of existing buildings. These panels can be installed as an additional layer on exterior walls, effectively enhancing the thermal insulation of the structure. This upgrade can lead to substantial reductions in heating and cooling costs, making older buildings more energy-efficient and environmentally friendly.

The process of retrofitting with aluminum foam sandwich panels is relatively straightforward and non-invasive. The panels can be attached to existing wall structures without the need for extensive modifications. This ease of installation makes them an attractive option for building owners looking to upgrade their properties without significant disruption to occupants.

Acoustic Improvements in Industrial and Commercial Spaces

Industrial facilities and commercial spaces often struggle with noise pollution. Retrofitting these spaces with aluminum foam sandwich panels can significantly improve their acoustic properties. The sound-absorbing characteristics of the foam core help to reduce echo and reverberation, creating a more comfortable environment for workers and visitors.

In retrofitting applications, these panels can be used to create sound barriers or partitions within large open spaces. They can also be applied to ceilings and walls to absorb ambient noise, particularly useful in spaces like open-plan offices, factories, or warehouses where noise reduction is crucial for productivity and worker well-being.

Structural Reinforcement and Weight Reduction

For older buildings requiring structural reinforcement, aluminum foam sandwich panels offer a lightweight solution that doesn't add significant load to the existing structure. These panels can be used to strengthen floors, walls, or roofs without the need for extensive and costly foundation reinforcements that might be necessary with heavier materials.

In retrofit projects where weight reduction is a priority, such as in historic buildings with aging structural supports, replacing traditional materials with aluminum foam sandwich panels can significantly decrease the overall load. This weight reduction can extend the lifespan of the building and improve its resilience to environmental factors like seismic activity.

Fire Safety Upgrades

Improving fire safety in existing structures is another crucial retrofit application for aluminum foam sandwich panels. These panels can be installed as fire-resistant barriers in walls, ceilings, and doors, enhancing the overall fire safety of the building. The foam core's inherent fire-resistant properties help to slow the spread of flames and reduce heat transfer during a fire event.

In industrial settings, where fire hazards are a significant concern, retrofitting with aluminum foam sandwich panels can create safer work environments. These panels can be used to construct fire-resistant enclosures around high-risk areas or to upgrade existing fire barriers, providing valuable time for evacuation and fire suppression efforts in case of an emergency.

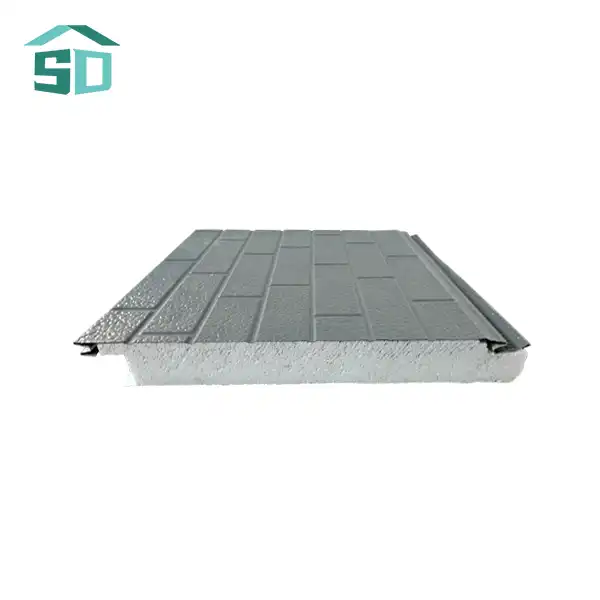

Aesthetic Renovations

Beyond their functional benefits, aluminum foam sandwich panels offer opportunities for aesthetic improvements in retrofit projects. These panels can be finished with a variety of coatings and textures, allowing for a modern update to the exterior appearance of older buildings. This aesthetic upgrade can be particularly valuable for commercial properties looking to attract new tenants or improve their market value.

In historic preservation projects, aluminum foam sandwich panels can be used to create lightweight, reversible additions that respect the original structure while providing modern amenities. Their versatility in design and finish allows architects to seamlessly integrate new elements with historical facades, balancing preservation with contemporary functionality.

Conclusion

Aluminum foam sandwich panels have emerged as a versatile and high-performance material with a wide range of applications across various industries. Their unique combination of lightweight properties, strength, thermal insulation, and sound dampening capabilities make them ideal for both new construction and retrofit projects. From aerospace and automotive engineering to architecture and marine applications, these innovative panels continue to push the boundaries of what's possible in material science and engineering. As we look towards a future focused on sustainability and efficiency, aluminum foam sandwich panels stand out as a solution that can significantly contribute to energy-efficient, safe, and aesthetically pleasing structures.

For those interested in exploring the potential of aluminum foam sandwich panels for their projects, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. As a leading aluminum foam sandwich panels supplier, we are committed to providing innovative solutions that meet the evolving needs of various industries. To learn more about how our aluminum foam sandwich panels can benefit your next project, please contact us at info@sdqsc.com.

FAQs

What are the main advantages of using aluminum foam sandwich panels?

Aluminum foam sandwich panels offer a unique combination of lightweight properties, high strength-to-weight ratio, excellent thermal insulation, sound dampening capabilities, energy absorption, and fire resistance. These advantages make them suitable for a wide range of applications across various industries.

Can aluminum foam sandwich panels be recycled?

Yes, aluminum foam sandwich panels are highly recyclable. As they are primarily composed of aluminum, they can be recycled at the end of their life cycle, aligning with sustainable construction practices.

Are aluminum foam sandwich panels suitable for retrofit projects?

Absolutely. These panels are excellent for retrofit projects, particularly for enhancing energy efficiency, improving acoustics, providing structural reinforcement, upgrading fire safety, and giving aesthetic renovations to existing buildings.

References

1. Ashby, M. F., et al. (2000). Metal foams: a design guide. Elsevier.

2. Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in materials science, 46(6), 559-632.

3. Baumeister, J., Banhart, J., & Weber, M. (1997). Aluminium foams for transport industry. Materials & Design, 18(4-6), 217-220.

4. García-Moreno, F. (2016). Commercial applications of metal foams: Their properties and production. Materials, 9(2), 85.

5. Wadley, H. N. (2002). Cellular metals manufacturing. Advanced Engineering Materials, 4(10), 726-733.