- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Save Time on Installation with Metal Carved Panels

In the world of modern construction and design, efficiency and aesthetics go hand in hand. Metal carved boards have emerged as a game-changer, offering a perfect blend of beauty and practicality. These innovative panels not only transform spaces with their elegant designs but also significantly reduce installation time, making them a favorite among architects, contractors, and homeowners alike. Let's delve into how metal carved boards are revolutionizing the construction industry and why they might be the perfect solution for your next project.

The Evolution of Metal Carved Boards in Construction

Metal carved boards have come a long way from their humble beginnings. Initially used primarily for decorative purposes, these panels have evolved into versatile building materials that offer both form and function. The advancement in manufacturing techniques has allowed metal carved board suppliers to create products that are not only visually stunning but also durable and easy to install.

From Ornamental to Functional: The Journey of Metal Carved Boards

Historically, metal carving was a labor-intensive craft, reserved for high-end architectural details and artistic expressions. However, modern technology has transformed this art form into a practical building solution. Today's metal carved boards are engineered to meet stringent construction standards while maintaining their aesthetic appeal. This evolution has opened up new possibilities in architectural design, allowing for the seamless integration of art and functionality in building facades.

Innovations in Metal Carved Board Manufacturing

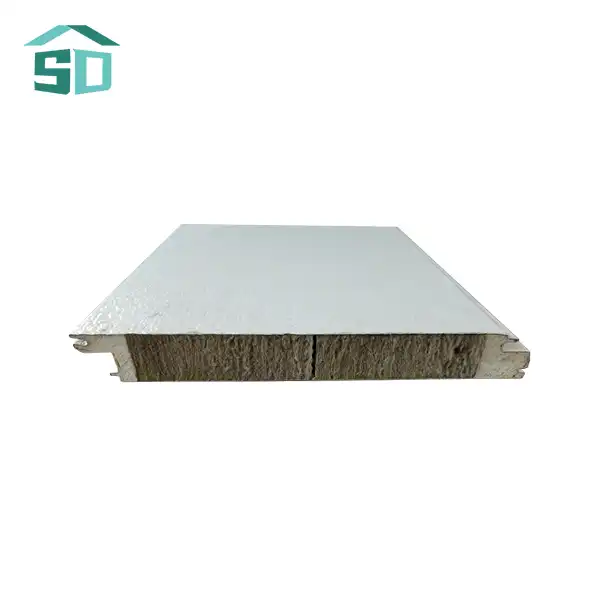

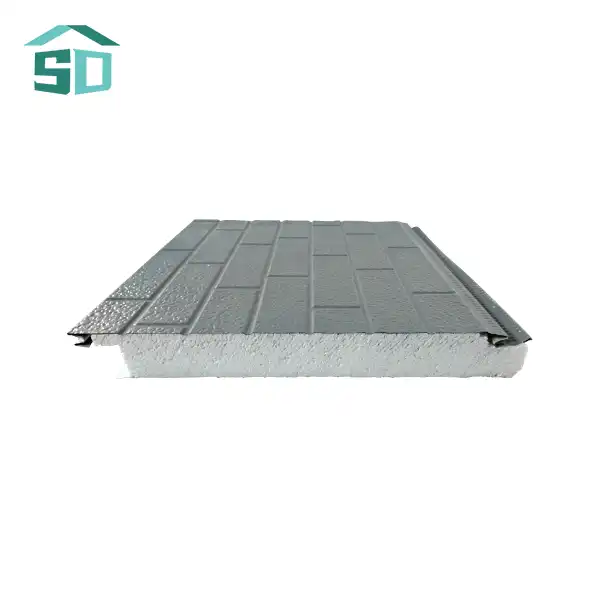

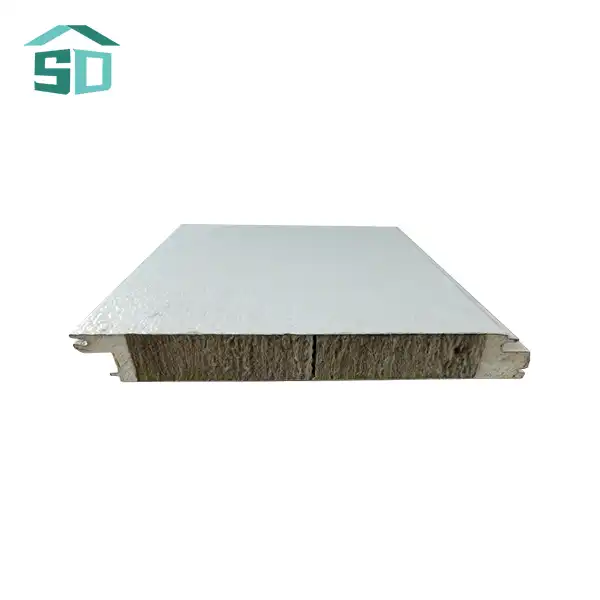

The manufacturing process of metal carved boards has seen significant advancements. State-of-the-art production lines and quality control systems ensure that each panel meets exacting standards. For instance, at Weifang Sandong Building Materials Co., Ltd., rigorous testing is conducted on steel coils, aluminum foil, and polyurethane components. This includes comprehensive inspections of product thickness, paint film thickness, mechanical strength, flame retardancy, and overall appearance. Such meticulous attention to detail results in metal carved boards that are not only beautiful but also reliable and consistent in quality.

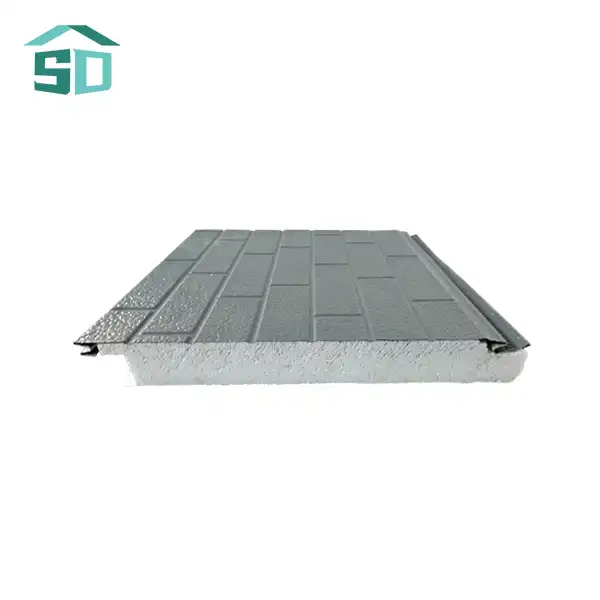

The Rise of Customization in Metal Carved Boards

One of the most exciting developments in the metal carved board industry is the ability to customize designs. Advanced CNC machines and computer-aided design software allow metal carved board suppliers to offer an unprecedented level of personalization. Architects and designers can now create bespoke patterns that reflect the unique character of each project, from intricate traditional motifs to bold contemporary designs. This flexibility has made metal carved boards a popular choice for a wide range of applications, from residential homes to commercial complexes.

The Technical Marvels of Metal Carved Boards

Metal carved boards are not just about aesthetics; they are technological marvels packed with features that make them ideal for modern construction. Understanding these technical aspects is crucial for appreciating why these panels are becoming increasingly popular in the building industry.

Strength and Durability: The Backbone of Metal Carved Boards

One of the standout features of metal carved boards is their exceptional strength-to-weight ratio. Despite their intricate designs, these panels are incredibly durable. The products from Weifang Sandong Building Materials Co., Ltd., for example, boast a compressive strength of 52.7kpa. This robustness ensures that the panels can withstand various environmental stresses, from high winds to heavy snow loads, without compromising their structural integrity or aesthetic appeal.

Thermal Performance: A Hidden Benefit of Metal Carved Boards

Beyond their visual appeal, metal carved boards offer impressive thermal performance. With a thermal conductivity of 0.018W/m.k and a thermal resistance of 2.09m2k/w, these panels contribute significantly to a building's energy efficiency. This insulating property helps maintain comfortable indoor temperatures, reducing the load on HVAC systems and potentially lowering energy costs. The thermal performance of metal carved boards makes them an excellent choice for both hot and cold climates.

Fire Safety: A Critical Aspect of Metal Carved Boards

Safety is paramount in construction, and metal carved boards excel in this area. These panels are designed to meet stringent fire safety standards, typically achieving a fire-protection rating of B1/B2. This classification indicates that the products are highly resistant to fire, providing an additional layer of safety to buildings. The non-flammable nature of metal carved boards makes them an ideal choice for both residential and commercial structures where fire safety is a critical concern.

Installation Efficiency: The Game-Changer of Metal Carved Boards

One of the most significant advantages of metal carved boards is the ease and speed of installation. This efficiency not only saves time but also reduces labor costs, making these panels an attractive option for various construction projects.

Streamlined Installation Process of Metal Carved Boards

The installation of metal carved boards is remarkably straightforward, thanks to their innovative design. These panels are typically lightweight, making them easy to handle and position. The installation process usually involves a few simple steps: surface preparation, accurate measurement and cutting of the metal carved boards, secure mounting using appropriate adhesives and fasteners, and final touches such as sealing or additional coatings if necessary. This streamlined process allows for rapid installation, significantly reducing project timelines.

Tools and Techniques for Efficient Metal Carved Board Installation

To maximize the efficiency of metal carved board installation, it's essential to use the right tools and techniques. Specialized cutting tools designed for metal panels ensure clean, precise cuts without damaging the intricate designs. Adhesives and fasteners specifically formulated for metal carved boards provide secure attachment while preserving the panel's integrity. Some metal carved board suppliers, like Weifang Sandong Building Materials Co., Ltd., offer complementary accessories such as edge trims and sealants, further simplifying the installation process and ensuring a polished final look.

Training and Expertise in Metal Carved Board Installation

While metal carved boards are designed for easy installation, proper training can further enhance efficiency. Many metal carved board suppliers offer installation workshops or detailed guidelines to ensure that contractors and installers are well-versed in the best practices for handling these specialized panels. This expertise not only speeds up the installation process but also helps prevent common mistakes that could compromise the panels' performance or appearance. As the popularity of metal carved boards grows, so does the pool of skilled installers, making it easier for projects to benefit from this efficient building solution.

Conclusion

Metal carved boards represent a significant leap forward in construction technology, offering a unique combination of aesthetic appeal, durability, and installation efficiency. Their versatility makes them suitable for a wide range of applications, from residential homes to commercial complexes. By choosing metal carved boards, builders and homeowners can save valuable time during installation without compromising on quality or design. As the construction industry continues to evolve, products stand out as a solution that meets the demands of modern building practices while providing the flexibility to create truly distinctive architectural statements.

Are you ready to transform your next construction project with the elegance and efficiency of metal carved boards? Weifang Sandong Building Materials Co., Ltd. offers a wide range of customizable metal carved board solutions to suit your specific needs. Whether you're planning a new construction or a renovation, our expert team is here to help you choose the perfect metal carved boards for your project. Contact us today at info@sdqsc.com to learn more about how our products can save you time and elevate your design.

FAQ

What are the main advantages of using metal carved boards?

Metal carved boards offer aesthetic appeal, durability, thermal insulation, fire resistance, and easy installation. They are versatile, customizable, and suitable for various applications in construction and design.

How do metal carved boards contribute to energy efficiency?

With their excellent thermal performance (thermal conductivity of 0.018W/m.k), metal carved boards help maintain indoor temperatures, reducing HVAC load and potentially lowering energy costs.

Are metal carved boards suitable for both interior and exterior use?

Yes, metal carved boards are designed for both interior and exterior applications. They come in different thicknesses (10mm for interior, 16mm/20mm for exterior) to suit various needs.

How do I maintain metal carved boards?

Metal carved boards are low maintenance. They resist fading, chipping, and peeling, requiring minimal upkeep to maintain their appearance over time.

References

1. Weifang Sandong Building Materials Co., Ltd. Official Product Catalog (2023)

2. International Journal of Architectural Engineering and Design, "Advancements in Metal Cladding Technologies" (2022)

3. Building Science Corporation, "Thermal Performance of Exterior Wall Systems" (2021)

4. National Fire Protection Association, "Fire Safety in Building Materials" (2023)

5. Construction Management Journal, "Efficiency in Modern Building Techniques" (2022)