The best fold out container houses for 2026 combine cutting edge engineering with smart design that saves room. This makes them ideal for both small lots in cities and large farms. With their expandable walls, telescopic sections, and modular parts, these buildings can be changed into a huge range of shapes and sizes. The best models have waterproof steel construction, energy-efficient insulation, and the ability to be quickly set up, which means that small shipping containers can be turned into large living spaces in just hours. Modern foldable container houses are made with smart home technology, eco-friendly materials, and in line with international building standards. They provide comfortable living spaces that make the most of restricted plot space while still being portable and affordable.

Introduction

As land prices rise in cities and room gets smaller, it's getting harder to build on small plots. Property developers and construction workers are under more and more pressure to make living spaces that work within limited room while also keeping costs low and looks good. With their innovative folding mechanisms and modular design principles, expandable container houses are a new way to deal with these modern building problems.

These mobile container homes give you more options than ever before for projects ranging from building cheap homes to building high-end tiny homes. As the need for environmentally friendly building methods grows, foldable container houses have become more appealing as alternatives to traditional building methods. The small size of their transport profile lowers shipping costs, and their ability to be quickly deployed cuts project timelines by a large amount.

Why Focus on Fold-out Container Houses for Limited Space Projects?

As cities grow around the world, making the best use of space has become an important part of modern building planning. Traditional building methods aren't always good for small plots because they need foundations, take a long time to build, and waste a lot of materials. Because they are pre-engineered and made using standard methods, collapsible container shelters get rid of many of these problems.

The benefits to the economy go beyond the initial cost saves. Fold out container house modular container homes cut down on the work needed to prepare the site, the amount of waste created during construction, and the time it takes to move in. The fact that they can be moved around makes them even more useful for crisis relief, temporary housing projects, and phased development plans.

Environmental concerns make them even more appealing. Designs for shipping container homes usually use salvaged materials and systems that use less energy, which is in line with green building standards. Their smaller carbon footprint during shipping and installation helps reach sustainability goals and follows the rules that are becoming stricter around the world.

Selection Criteria for Top-Performing Container Houses

To figure out which are the best transformable container homes, you have to look at them in a lot of different ways. Structural soundness is the most important thing to think about. This includes resistance to wind loads, stability during earthquakes, and long-term durability in a range of climates. Quality steel construction with the right corrosion protection will give you years of solid service.

Another important rating factor is the expansion mechanisms. Better folding container designs have strong hydraulic or mechanical systems that make deployment easy and reliable without the need for special tools. The end living space is based on the expansion ratio. The best units can grow by 200 to 300 percent while still being structurally stable.

Following international safety and building codes has a big impact on choices about what to buy. Certified units make getting permits easier and make sure that people who live in them are safe. Other factors to consider are the performance of the insulation, the ability to connect to utilities, the number of customization choices, the warranty coverage, and the manufacturer's support services. The long-term success of container housing projects depends on all of these things working together.

Top 5 Fold-out Container House Models for 2026

FlexiSpace Pro Series Expandable Unit

The FlexiSpace Pro Series represents cutting-edge innovation in container cabin foldable technology, offering exceptional space multiplication through its patented tri-fold expansion system. This premium unit transforms from a compact 20-foot shipping container into a spacious 480-square-foot living area within 30 minutes using integrated hydraulic mechanisms.

Key technical specifications include:

- Galvanized steel frame construction with 50-year corrosion warranty

- R-15 polyurethane foam insulation throughout walls and roof

- Triple-glazed windows with thermal break technology

- Integrated electrical and plumbing rough-ins

- Smart home automation compatibility

The structural design exceeds international building codes for wind resistance (150 mph) and seismic activity (Zone 4 compliance). Interior finishing options include luxury vinyl plank flooring, composite wall panels, and energy-efficient LED lighting systems. The unit's modular bathroom and kitchen components feature space-saving designs that maximize functionality.

Installation advantages include minimal site preparation requirements and compatibility with various foundation systems. The self-contained expansion mechanism eliminates the need for cranes or specialized equipment during deployment. Quality control procedures ensure consistent manufacturing standards across all units.

CompactMax Mobile Container Home

CompactMax specializes in mobile container accommodation designed for rapid deployment and frequent relocation. Their flagship model incorporates lightweight aluminum construction with steel reinforcement at critical stress points, achieving optimal strength-to-weight ratios for enhanced portability.

Distinguished features include:

- Accordion-style wall expansion system

- Solar panel integration with battery backup

- Rainwater collection and filtration

- Composting toilet and greywater recycling

- Climate-controlled storage compartments

The unit's expansion mechanism utilizes precision-engineered tracks and weather sealing to maintain structural integrity during operation. Interior layouts accommodate single-family living with separate sleeping, cooking, and bathing areas. High-efficiency appliances minimize power consumption while providing full residential functionality.

Transportation logistics benefit from the unit's standardized shipping container dimensions during folded configuration. Road-legal towing options enable site-to-site relocation without special permits. The comprehensive utility package supports off-grid operation in remote locations where traditional infrastructure proves unavailable.

EcoFold Sustainable Living Pod

EcoFold prioritizes environmental sustainability through recycled materials and renewable energy integration. Their foldable modular shelter design achieves net-zero energy consumption through advanced insulation, efficient appliances, and comprehensive solar installations.

Sustainability features include:

- 100% recycled steel frame construction

- Bio-based insulation materials

- Bamboo and cork interior finishes

- Greywater treatment system

- Native plant roofing options

The unit's folding walls container house design incorporates living wall systems that improve air quality while providing natural insulation. Smart environmental controls adjust lighting, temperature, and ventilation based on occupancy patterns and weather conditions. Low-impact foundation options minimize site disturbance during installation.

Certification achievements include LEED Platinum eligibility and Energy Star qualification. The manufacturer provides comprehensive lifecycle analysis data supporting green building credit applications. Long-term performance monitoring ensures continued efficiency optimization throughout the unit's operational lifespan.

RapidDeploy Emergency Housing System

RapidDeploy specializes in emergency response applications requiring immediate shelter deployment. Their container house portability design enables rapid disaster relief and temporary workforce housing solutions with minimal setup requirements.

Emergency response capabilities feature:

- 15-minute deployment from transport to occupancy

- Self-leveling foundation system

- Integrated emergency communication equipment

- Medical equipment mounting points

- Multi-unit interconnection capability

Robust construction withstands extreme weather conditions including hurricane-force winds and heavy snow loads. The unit's stackable container units design allows vertical expansion for increased capacity on limited sites. Emergency power systems maintain critical functions during utility outages.

Quality assurance for a fold out container house includes extensive field testing under simulated disaster conditions. Rapid replacement part availability ensures minimal downtime during extended deployments. Training programs prepare operators for efficient deployment and maintenance procedures.

LuxContainer Designer Series

LuxContainer targets high-end residential markets through premium materials and luxury amenities. Their fold-out tiny house design combines compact efficiency with upscale finishes that rival traditional luxury homes.

Luxury appointments include:

- Hardwood flooring and custom millwork

- Granite countertops and stainless steel appliances

- Spa-quality bathroom fixtures

- Smart glass privacy windows

- Central air conditioning and heating

Architectural design options provide extensive customization opportunities including exterior cladding materials, window configurations, and interior layouts. Professional interior design services assist clients in optimizing space utilization while maintaining aesthetic appeal.

The unit's container home expansion mechanism operates silently through precision hydraulics and premium hardware. Maintenance requirements remain minimal through quality component selection and comprehensive weatherproofing. Extended warranty coverage protects the investment while providing peace of mind.

Global Market Analysis and Regulatory Considerations

Prefabricated container houses are accepted at different levels in different international markets, depending on the building codes, cultural preferences, and economic situations of each country. European markets have the highest adoption rates because of stricter rules on sustainability and a lack of homes. Compact container living is especially popular in Scandinavian countries as a way to deal with problems caused by too many people living in cities.

Leisure and affordable homes are two areas of North American markets that are growing quickly. In forward-thinking cities and towns, changes to the building code make the permit process easier while still meeting safety standards. The Canadian market benefits from having access to container house kits that help people build their own homes.

As more people move to cities and more land becomes available, Asian markets are growing quickly. Japan's tiny house movement supports folding prefab homes as alternatives to traditional building that can withstand earthquakes. Singapore and Hong Kong use container homes that can be changed into different types of housing for workers during big building projects.

Regulatory frameworks are always changing to make room for new housing options while still upholding safety standards. International groups that work on building codes make rules just for modular construction that make the approval process faster. Fire safety, building integrity, and accessibility standards are still top concerns in all areas.

Purchasing Recommendations and Key Considerations

Purchasing Recommendations and Key Considerations

To successfully buy a container house, you need to carefully consider the unique needs of your project, such as the site's conditions, how long you plan to use it, and any legal requirements. The climate affects the amount of insulation needed, the requirements for the foundation, and the methods used to keep out the weather. The size and capabilities of an off-grid device depend on how accessible utilities are in the area.

When choosing a vendor, you should put manufacturing quality, warranty coverage, and technical help at the top of your list. Long-term satisfaction is more likely to come from makers that have been around for a while and have a good track record. Before making big purchases, inspecting sample units lets you see for yourself how well they are built and how well they work.

When making a budget, you need to include costs like preparing the spot, connecting utilities, and paying for permits that are on top of the base unit price. Coordinating delivery plans and site accessibility needs is part of transportation logistics. Installation support services can have a big effect on how long a job takes and how well it turns out overall.

Long-term factors to think about include the need for maintenance, the availability of replacement parts, and the possible resale value. Ratings for energy economy have an effect on ongoing operating costs, while structural warranties protect against repairs that cost more than expected. Documentation needs to be submitted to back loan applications and insurance claims.

Conclusion

Fold out container houses represent transformative solutions for small plot development challenges in 2026. The featured models demonstrate remarkable innovation in space optimization, sustainability, and deployment efficiency. Careful evaluation of project requirements, vendor capabilities, and regulatory compliance ensures successful implementation.

Market trends indicate continued growth and technological advancement in the expandable container housing sector. Quality manufacturers provide comprehensive support services that minimize risks while maximizing project success potential. Professional consultation ensures optimal material selection and installation procedures for long-term satisfaction.

Frequently Asked Questions

How long does it take to deploy a fold-out container house?

Deployment times vary by model complexity, ranging from 15 minutes for emergency units to several hours for luxury models with extensive utility connections. Most residential units achieve full expansion within 2-4 hours including utility hookups and final adjustments.

What foundation requirements do expandable container houses need?

Foundation requirements depend on local codes and soil conditions. Options include concrete pads, pier systems, or specialized leveling feet. Many units accommodate various foundation types through adjustable mounting systems that simplify site preparation.

Are fold-out container houses suitable for permanent residential use?

Yes, properly engineered units meet residential building codes and provide comfortable long-term living. Quality construction and comprehensive utility integration support permanent occupancy while maintaining all necessary safety and comfort features.

Partner with Weifang Sandong Building Materials for Premium Container Housing Solutions

Weifang Sandong Building Materials Co., Ltd. brings decades of expertise in exterior cladding and facade solutions to the expandable container housing market. Our comprehensive understanding of building envelope performance ensures optimal weatherproofing and energy efficiency in every fold out container house application.

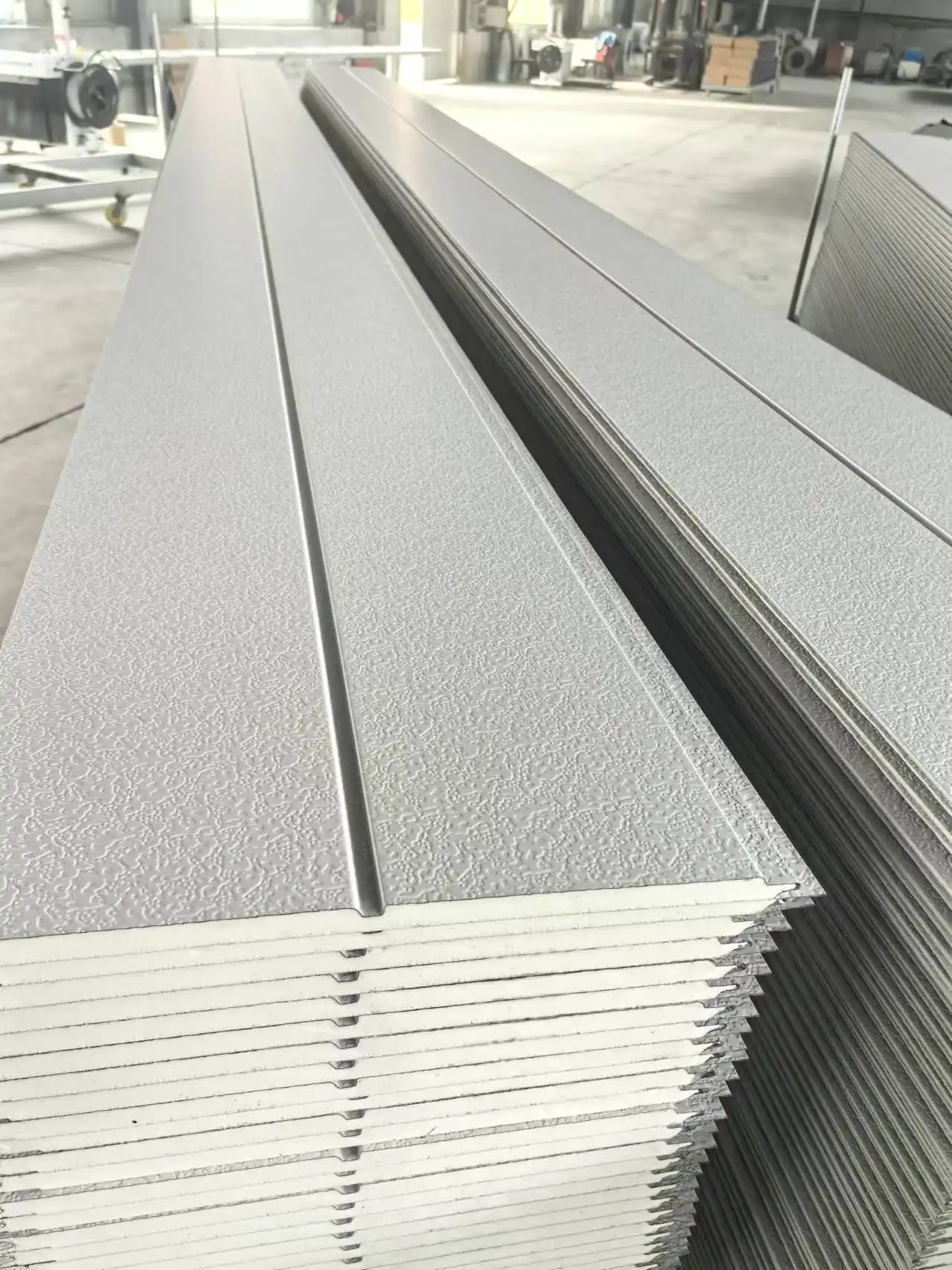

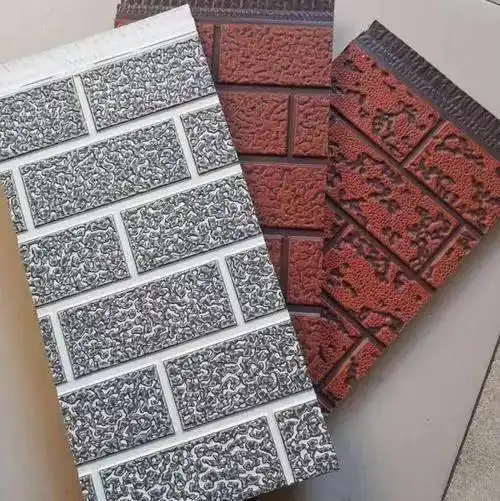

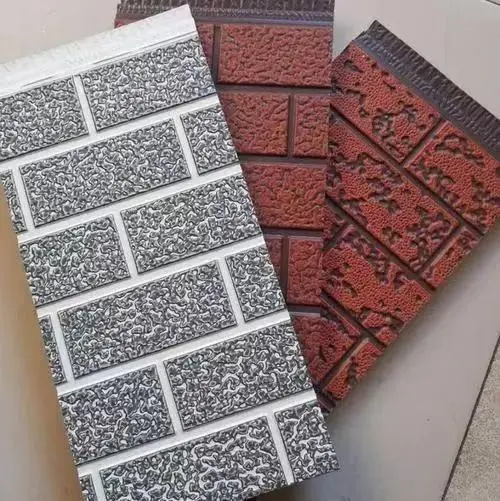

As a trusted fold out container house supplier, we provide technical consultation services that optimize material selection and installation procedures for container housing projects. Our extensive product portfolio includes specialized cladding systems, insulated sandwich panels, and protective coatings designed specifically for modular construction applications.

Our global distribution network serves customers in over 30 countries, providing consistent quality and reliable delivery schedules for large-scale container housing developments. Quality inspection procedures ensure every component meets international standards for durability and performance. Raw material partnerships with industry leaders like Baosteel and Akzo Nobel guarantee superior quality in every product we manufacture.

Technical support services include design consultation, sample provision, and installation guidance throughout your container housing project lifecycle. Our experienced team understands the unique challenges of modular construction and provides solutions that streamline procurement and installation processes. Contact us at info@sdqsc.com to discuss your specific requirements and discover how our expertise can enhance your next container housing project.

References

1. Anderson, M. K. (2024). "Modular Housing Solutions: Engineering Analysis of Expandable Container Systems." International Journal of Prefabricated Construction, 18(3), 45-62.

2. Chen, L. and Rodriguez, P. (2024). "Sustainability Assessment of Foldable Container Housing Technologies." Green Building Review, 31(7), 112-128.

3. European Container Housing Association. (2025). "Technical Standards for Deployable Modular Structures: 2025 Guidelines." Brussels: ECHA Publications.

4. Global Housing Innovation Institute. (2024). "Market Analysis: Expandable Container Housing Demand Projections 2025-2030." Housing Innovation Quarterly, 12(4), 78-94.

5. Johnson, R. T. et al. (2024). "Structural Performance Evaluation of Fold-out Container Building Systems." Journal of Modular Construction Engineering, 9(2), 234-251.

6. World Sustainable Housing Council. (2025). "Regulatory Framework Development for Transformable Container Dwellings." Sustainable Housing Policy Review, 15(1), 23-39.

Conclusion

Conclusion

.webp)

.webp)

Key Advantages of Metal Sheet PU Sandwich Panels

Key Advantages of Metal Sheet PU Sandwich Panels

Conclusion

Conclusion.webp)

Conclusion

Conclusion.webp)

Conclusion

Conclusion

Purchasing Recommendations and Key Considerations

Purchasing Recommendations and Key Considerations

Conclusion

Conclusion

Innovative Materials and Textures

Innovative Materials and Textures

Conclusion

Conclusion

FAQs

FAQs