The Science Behind Aluminum Foam Sandwich Panels and Sound Insulation

To comprehend how aluminum foam sandwich panels enhance soundproofing, it's crucial to delve into the science of sound transmission and absorption. Sound waves, when encountering a barrier, can be reflected, absorbed, or transmitted through the material. The effectiveness of a material in soundproofing depends on its ability to minimize sound transmission while maximizing absorption and reflection.

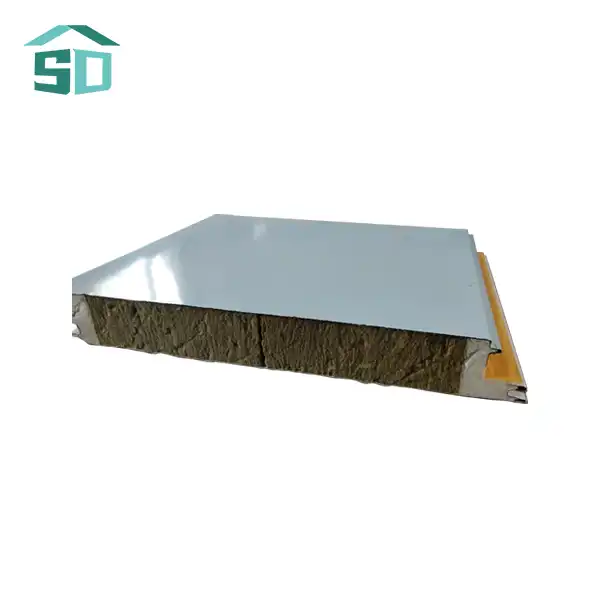

Structure and Composition

Aluminum foam sandwich panels consist of three main components:

- Outer Layers: Solid aluminum sheets (thickness ranging from 0.23mm to 0.27mm)

- Core: Lightweight aluminum foam

- Bonding Agent: Adhesive that joins the layers

This unique composition creates a material with exceptional sound-damping properties. The solid aluminum outer layers act as reflectors, bouncing back a significant portion of incoming sound waves. Meanwhile, the porous aluminum foam core plays a crucial role in absorbing and dissipating sound energy.

Sound Wave Interaction

When sound waves encounter an aluminum foam sandwich panel, several processes occur simultaneously:

1.Reflection: The solid aluminum outer layers reflect a portion of the sound waves.

2.Absorption: The aluminum foam core traps sound waves within its complex network of pores.

3.Dissipation: As sound waves travel through the foam, they lose energy through friction and thermal conversion.

4.Scattering: The irregular structure of the foam core scatters sound waves, further reducing their intensity.

This multi-faceted approach to sound management results in significant noise reduction across a wide range of frequencies. The thermal conductivity of 0.018W/m.k and thermal resistance of 2.09m2k/w further contribute to the panel's insulating properties, not just for sound but also for temperature control.

Comparative Analysis: Aluminum Foam Sandwich Panels vs. Traditional Soundproofing Materials

To truly appreciate the soundproofing capabilities of aluminum foam sandwich panels, it's valuable to compare them with traditional materials used for acoustic insulation. This comparison highlights the unique advantages that make these panels an increasingly popular choice in modern construction and renovation projects.

Performance Metrics

When evaluating soundproofing materials, several key metrics come into play:

- Sound Transmission Class (STC): Measures how well a material blocks airborne sound.

- Noise Reduction Coefficient (NRC): Indicates a material's ability to absorb sound.

- Impact Insulation Class (IIC): Assesses effectiveness against impact noise.

Aluminum foam sandwich panels generally excel in these areas due to their composite structure. While exact values can vary based on specific compositions and thicknesses, these panels often outperform traditional materials in overall sound insulation efficiency.

Comparison with Common Materials

Let's examine how aluminum foam sandwich panels stack up against some traditional soundproofing options:

1. Fiberglass Insulation:

- Aluminum Foam Panels: Superior sound absorption across a wider frequency range, better structural integrity.

- Fiberglass: Good absorption but less effective at blocking low-frequency sounds, can degrade over time.

2. Mass Loaded Vinyl (MLV):

- Aluminum Foam Panels: Comparable sound blocking with added benefits of thermal insulation and fire resistance.

- MLV: Effective at blocking sound but lacks thermal insulation properties, can be heavy.

3. Acoustic Foam:

- Aluminum Foam Panels: Better overall insulation, durability, and multi-functional benefits.

- Acoustic Foam: Good at absorbing high-frequency sounds but less effective for low frequencies, limited structural use.

The aluminum foam sandwich panels, with their fire-protection rating of B1/B2, waterproof rate of 0.0008, and wind resistance of 8.0 Kpa, offer a comprehensive solution that goes beyond mere soundproofing. Their compressive strength of 52.7kpa further underscores their structural advantages over many traditional materials.

Practical Applications and Installation Considerations

The versatility of aluminum foam sandwich panels extends their use across various sectors, from residential to commercial and industrial applications. Understanding where and how to implement these panels can maximize their soundproofing benefits while taking advantage of their other properties.

Ideal Applications

Aluminum foam sandwich panels are particularly well-suited for:

- Recording Studios: Where sound isolation is paramount.

- Office Spaces: To create quiet work environments in open-plan offices.

- Educational Facilities: To improve acoustics in classrooms and lecture halls.

- Residential Buildings: For noise reduction between apartments or from external sources.

- Industrial Settings: To contain machinery noise and improve worker comfort.

- Transportation: In vehicles and aircraft for noise reduction and thermal insulation.

The customizable nature of these panels, available in various thicknesses (interior 10mm, exterior 16mm/20mm) and widths (exterior 383mm, interior 450mm), allows for tailored solutions to specific acoustic challenges.

Installation Best Practices

To maximize the soundproofing effectiveness of aluminum foam sandwich panels:

1.Ensure Proper Sealing: Address potential air gaps which can significantly reduce soundproofing efficiency.

2.Consider Layering: In high-noise areas, using multiple layers can enhance sound insulation.

3.Combine with Other Materials: Integrating panels with other soundproofing elements can create a more comprehensive solution.

4.Professional Installation: Given the technical nature of soundproofing, professional installation is often recommended to ensure optimal performance.

The lightweight nature of these panels, coupled with their structural strength, makes installation more manageable compared to some heavier soundproofing alternatives. However, proper handling is crucial to maintain the integrity of the foam core.

Maintenance and Longevity

One of the standout highlights of aluminum froth sandwich boards is their moo support necessities and solidness. The corrosion-resistant nature of aluminum, combined with the panel's waterproof properties, guarantees long-lasting execution indeed in challenging situations. Customary visual assessments and essential cleaning are ordinarily adequate to keep up their viability over time.

Conclusion

Aluminum foam sandwich panels represent a significant advancement in soundproofing technology. Their unique structure, combining a lightweight aluminum foam core with solid aluminum outer layers, provides exceptional sound insulation properties. These boards not only successfully decrease commotion transmission but also offer extra benefits such as warm separator, fire resistance, and auxiliary quality. Their flexibility makes them reasonable for a wide extend of applications, from private to commercial and mechanical settings.

As we continue to seek innovative solutions for creating quieter, more comfortable spaces, aluminum foam sandwich panels stand out as a multifunctional option that addresses multiple construction needs simultaneously. Their ability to enhance soundproofing while contributing to energy efficiency and building safety makes them an attractive choice for modern construction and renovation projects.

For those interested in exploring the potential of aluminum foam sandwich panels for their soundproofing needs or other construction applications, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. To learn more about our exterior cladding and facade solutions, including aluminum foam sandwich panels, please contact us at info@sdqsc.com. Our team is ready to assist you in finding the perfect solution for your specific requirements, ensuring that you can create spaces that are not just quiet but also safe, energy-efficient, and aesthetically pleasing.