Understanding Metal Sandwich Panel Types and Applications

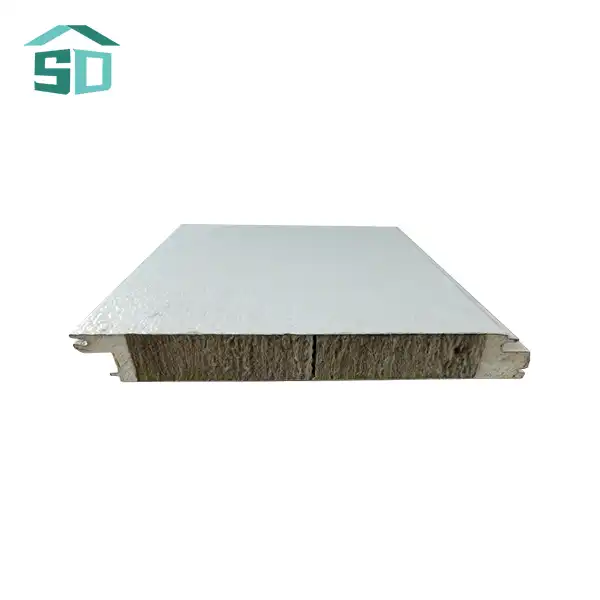

Metal sandwich panels are composite materials consisting of two metal facings bonded to an insulating core. These panels come in various types, each designed for specific applications and performance requirements.

Common Types of Metal Sandwich Panels

There are several types of metal sandwich panels available in the market:

- Polyurethane (PUR) Panels: Known for excellent thermal insulation and lightweight properties.

- Polystyrene (EPS) Panels: Offer good insulation at a more economical price point.

- Mineral Wool Panels: Provide superior fire resistance and sound insulation.

- Glass Wool Panels: Combine thermal insulation with acoustic performance.

Each type has its unique advantages, and the choice depends on the specific requirements of your project.

Versatile Applications Across Industries

Metal sandwich panels find applications in various sectors due to their adaptability and performance characteristics:

- Commercial Buildings: Offices, retail spaces, and warehouses

- Industrial Facilities: Factories, processing plants, and storage units

- Residential Complexes: Apartment buildings and modern homes

- Agricultural Structures: Barns, silos, and storage facilities

- Cold Storage: Food processing and pharmaceutical storage

The versatility of these panels makes them a popular choice for both new constructions and renovation projects.

Key Factors to Consider in Bulk Metal Sandwich Panel Purchases

When making a bulk purchase of metal sandwich panels, several crucial factors should be taken into account to ensure you're getting the best value for your investment.

Material Quality and Durability

The durability of metal sandwich panels is paramount, especially for bulk purchases in construction or industrial applications. It's essential to choose panels made with high-quality facing materials such as aluminum, galvanized steel, stainless steel, or copper. These materials provide varying degrees of resistance to corrosion, weathering, and mechanical damage. For projects in harsh climates or corrosive environments, stainless steel or coated steel options may offer superior performance. Long-lasting durability helps minimize maintenance costs and extends the building' service life.

Insulation Performance

The insulation core of metal sandwich panels is a critical factor in determining energy efficiency. The R-value, which quantifies thermal resistance, should align with the thermal performance requirements of your project. Polyurethane (PU) and expanded polystyrene (EPS) cores are widely used due to their excellent insulation capabilities and lightweight nature. For projects prioritizing fire safety, mineral wool is a preferred core option, offering both thermal insulation and non-combustibility. Proper insulation reduces heating and cooling demands, contributing to lower energy bills and environmental sustainability.

Fire Safety Ratings

Fire resistance is a non-negotiable prerequisite in safety-conscious development ventures. When assessing metal sandwich boards, check for compliance with globally recognized fire security certifications such as ISO 1182, CE EN 13501, or UL 723. Boards with mineral fleece centers are ordinarily classified as non-combustible and can contain fire spread successfully. Such items are particularly critical in offices like clinics, manufacturing plants, or high-occupancy buildings. Choosing boards with dependable fire evaluations upgrades generally building security and bolsters adherence to administrative guidelines and protections prerequisites.

Customization Options

The ability to customize panels to suit your specific project needs is invaluable. Consider suppliers who offer a range of:

- Size options: Customizable sizes to fit your exact specifications

- Thickness variations: Ranging from 30mm to 150mm to meet different insulation requirements

- Color choices: Multiple color options with various surface treatments like coating, painting, or anodizing

Installation Ease and Accessories

Efficient installation can significantly reduce construction time and labor costs. Look for panels designed for easy installation and consider the availability of complementary accessories such as:

- Sealants for enhanced insulation and moisture protection

- High-quality fasteners for secure installation

- Edge trims for a polished look and additional weather protection

Maximizing Value in Your Bulk Metal Sandwich Panel Purchase

To ensure you're getting the best value for your bulk purchase, consider these additional aspects:

Supplier Reputation and Quality Control

Select a provider with a solid, set up notoriety in the metal board industry. Dependable producers ordinarily work with progressed computerized generation lines and uphold strict quality control frameworks all through the fabricating handle. They conduct exhaustive assessments and execution tests on both crude materials and wrapped up boards. These assessments frequently incorporate checks on coating thickness, paint film consistency, mechanical quality, separator thickness, and fire retardancy. A provider that emphasizes comprehensive testing illustrates a commitment to conveying reliable, high-quality items for long-term execution.

Long-term Cost-Effectiveness

While initial costs are important, consider the long-term value of your investment. High-quality metal sandwich panels may have a higher upfront cost but can offer significant savings over time through:

- Reduced energy costs due to superior insulation

- Lower maintenance requirements

- Extended lifespan of the building envelope

Sustainability Considerations

With the developing accentuation on economical development, it's imperative to consider the natural affect of your metal sandwich board choice. Select for boards fabricated with eco-friendly or recyclable materials that back green building certifications such as LEED or BREEAM. A few providers utilize low-emission generation forms, renewable vitality, or reused metal in their fabricating. Choosing ecologically mindful boards not as it were diminishes your project's carbon impression but moreover adjusts with advanced building objectives centered on long-term maintainability and energy-efficient building execution.

Conclusion

Selecting the best metal sandwich panels for bulk purchase requires careful consideration of various factors, from material quality and insulation performance to customization options and long-term value. By thoroughly evaluating these aspects, B2B buyers can make informed decisions that align with their project goals and budget constraints. For more information on high-quality metal sandwich panels and expert guidance on bulk purchases, don't hesitate to reach out to us at info@sdqsc.com. Our team is ready to assist you in finding the perfect solution for your construction needs.