The Composition of Decorative Wall Insulation Panels

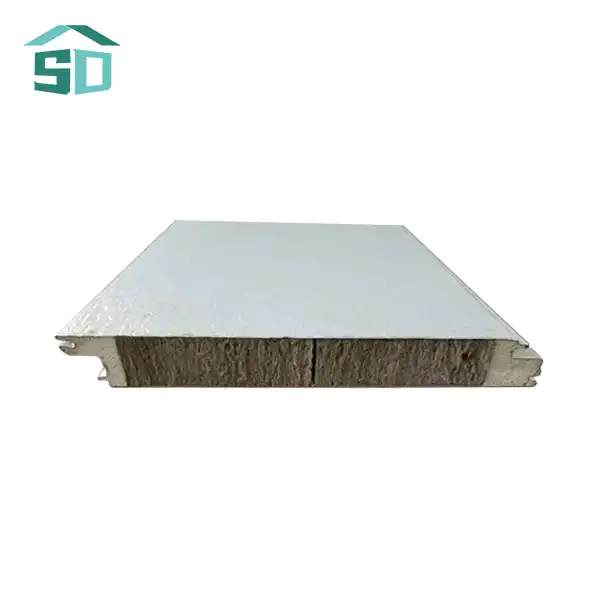

Core Insulation Materials

The heart of decorative wall insulation panels lies in their core materials. These materials are chosen for their superior insulating properties and ability to maintain thermal efficiency over time. Polyurethane foam is a popular choice due to its exceptional thermal conductivity of 0.018W/m.k, as seen in Weifang Sandong Building Materials Co., Ltd.'s panels. This low thermal conductivity translates to excellent heat retention and energy savings.

Expanded polystyrene (EPS) is another common core material, prized for its lightweight nature and moisture resistance. Mineral wool, derived from recycled materials, offers not only thermal insulation but also acoustic dampening properties, making it ideal for both residential and commercial applications.

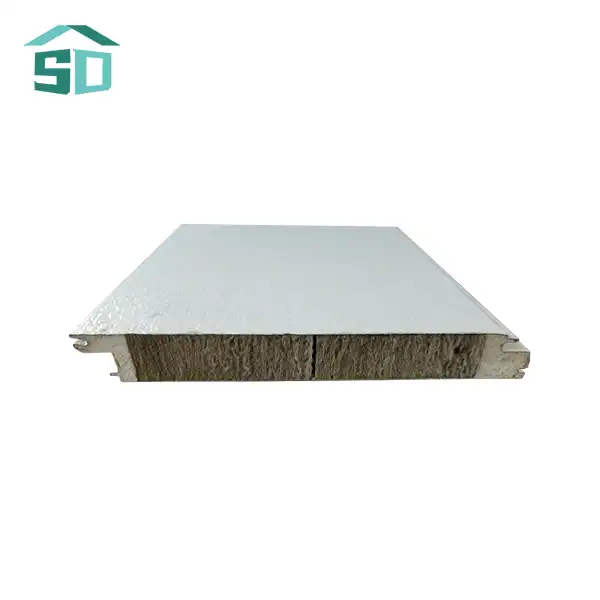

Outer Layer Materials

The exterior surfaces of decorative wall insulation panels are where aesthetics meet functionality. Metal facings, typically steel or aluminum with thicknesses ranging from 0.23mm to 0.27mm, provide durability and weather resistance. These metal surfaces can be coated or painted in a vast array of colors and patterns, allowing for unlimited design options to enhance any architectural style.

For a more natural look, wood veneers can be applied to the panel surfaces. These thin layers of real wood bring warmth and texture to interiors while maintaining the panel's insulating properties. Composite materials, often made from a blend of wood fibers and recycled plastics, offer another eco-friendly option that combines the look of wood with enhanced durability.

Protective Coatings and Finishes

To ensure longevity and performance, decorative wall insulation panels are often treated with specialized coatings. These can include UV-resistant finishes to prevent fading and deterioration from sun exposure, anti-corrosion treatments for metal surfaces, and fire-retardant coatings to achieve fire-protection ratings of B1 or B2. The addition of these protective layers contributes to the panels' impressive waterproof rate of 0.0008 and wind resistance of 8.0 Kpa, making them suitable for various climate conditions.

Performance Characteristics of Decorative Wall Insulation Panels

Thermal Efficiency

The primary function of decorative wall insulation panels is to provide superior thermal insulation. With a thermal resistance of 2.09m2k/w, these panels create an effective barrier against heat transfer, helping to maintain comfortable indoor temperatures year-round. This high level of insulation leads to reduced energy consumption for heating and cooling, resulting in lower utility bills and a smaller carbon footprint.

Structural Integrity

Despite their focus on insulation, these panels are not lacking in structural strength. With a compressive strength of 52.7kpa, they can withstand significant loads without deformation. This strength allows them to be used in various construction applications, from residential complexes to commercial buildings, without compromising on safety or durability.

Fire Safety and Weather Resistance

Safety is paramount in building materials, and decorative wall insulation panels are designed with this in mind. The fire-protection rating of B1/B2 ensures that these panels meet stringent safety standards, providing peace of mind to building occupants. Additionally, their high wind resistance and low waterproof rate make them ideal for use in areas prone to severe weather conditions, protecting buildings from the elements while maintaining their aesthetic appeal.

Installation and Customization of Decorative Wall Insulation Panels

Installation Methods

The installation of decorative wall insulation panels is designed to be straightforward, allowing for efficient construction processes. These panels can be installed using various methods, including mechanical fastening, adhesive application, or the use of furring strips for enhanced stability. The choice of installation method often depends on the specific building requirements and the panel type.

For exterior applications, panels with a thickness of 16mm or 20mm and a width of 383mm are commonly used. Interior panels are typically thinner at 10mm and wider at 450mm, allowing for easier coverage of internal walls. The versatility in installation methods and panel sizes enables architects and builders to adapt these panels to diverse construction projects, from new builds to renovations of historic structures.

Customization Options

One of the most compelling features of decorative wall insulation panels is their vast potential for customization. Manufacturers offer an extensive range of colors, textures, and patterns, allowing designers to create unique aesthetic solutions that complement any architectural vision. From sleek, modern metallic finishes to rustic wood-look panels, the possibilities are virtually limitless.

Custom designs can be achieved through various methods, including digital printing on metal surfaces, embossing patterns, or applying specialized coatings. This level of customization ensures that insulation panels can enhance the visual appeal of buildings while providing crucial energy-saving benefits.

Sustainability Considerations

As the development industry moves towards more maintainable hones, embellishing divider cover boards are advancing to meet these requests. Numerous producers are presently joining reused materials into their board generation, lessening squander and natural affect. The utilize of eco-friendly cover centers, such as mineral fleece made from reused glass, encourage contributes to the supportability of these items.

Additionally, the energy-saving properties of these boards play a critical part in lessening a building's generally natural impression. By progressing warm productivity, enriching divider cover boards offer assistance diminish vitality utilization over the life of the building, adjusting with green building benchmarks and contributing to a more maintainable future in development.

Conclusion

Decorative wall insulation panels represent a harmonious blend of form and function in modern construction materials. By combining high-performance insulation cores with customizable, aesthetically pleasing outer layers, these panels offer a comprehensive solution for energy-efficient, stylish building envelopes. Their versatility in design, ease of installation, and superior performance characteristics make them an invaluable asset for architects, builders, and property owners alike.

As the demand for energy-efficient and visually appealing buildings continues to grow, decorative wall insulation panels are poised to play an increasingly important role in the construction industry. Their ability to meet both aesthetic and functional requirements positions them as a key component in creating sustainable, comfortable, and beautiful spaces for generations to come.

For more information on decorative wall insulation panels and other exterior cladding solutions, please contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your next project.