The Composition and Recyclability of Aluminum Sandwich Panels

Aluminum sandwich panels are marvels of modern construction, combining durability, insulation, and aesthetic appeal. Their structure typically consists of two aluminum sheets bonded to a core material, creating a lightweight yet robust building component. The recyclability of these panels hinges on their composition:

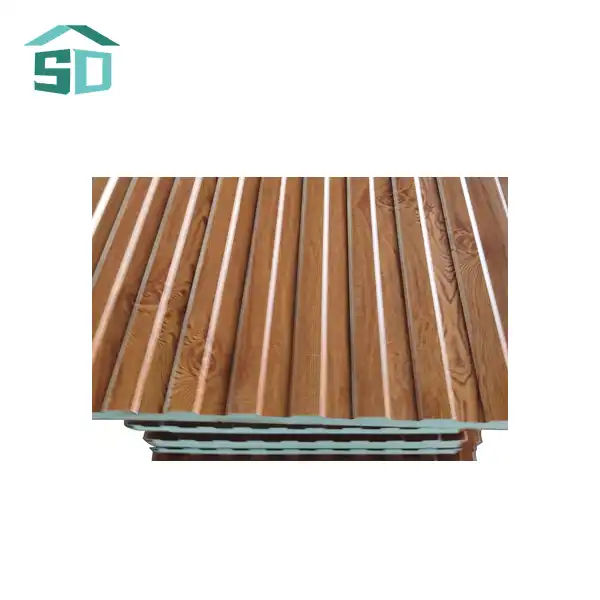

Aluminum Exterior Sheets

The outer layers of aluminum sandwich panels are the stars of the recycling show. Aluminum is renowned for its infinite recyclability without loss of quality. These sheets can be melted down and reprocessed into new aluminum products, conserving energy and raw materials. The recycling process for aluminum requires only 5% of the energy needed to produce new aluminum from bauxite ore, showcasing its environmental benefits.

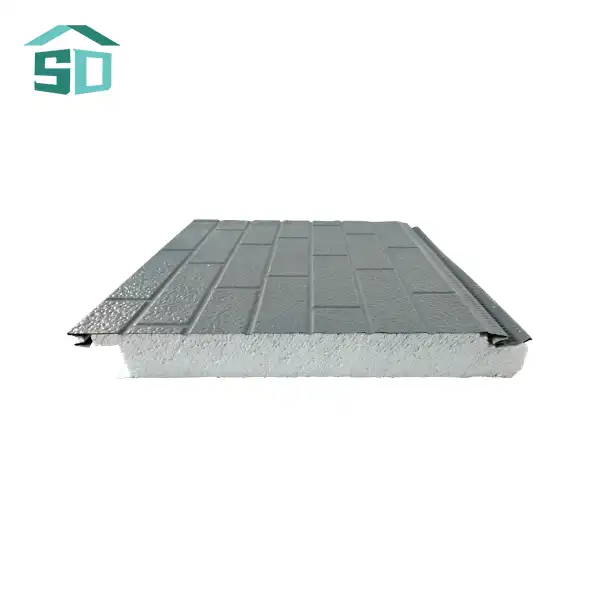

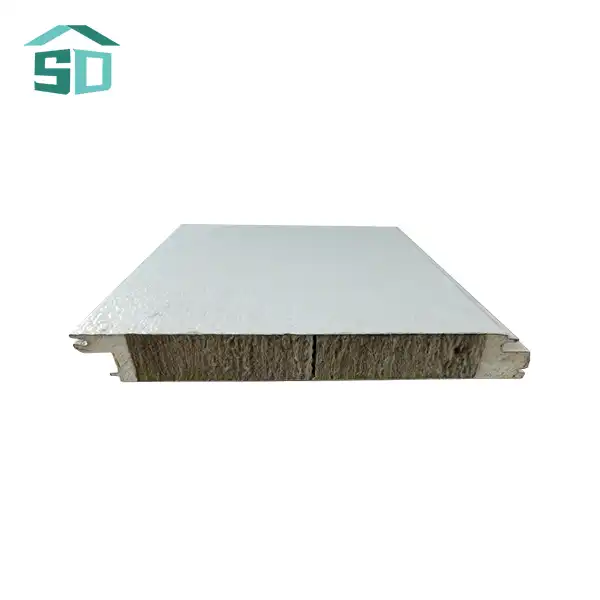

Insulation Core

The core material in aluminum sandwich panels varies but commonly includes:

- Polyurethane (PUR): While challenging to recycle, advancements in chemical recycling technologies are making it increasingly feasible to recover and repurpose PUR.

- Polystyrene: This material can be recycled, though the process is not as straightforward as aluminum recycling.

- Rock wool: Made from natural materials, rock wool is recyclable and can often be repurposed in other applications.

The recyclability of the core material depends on local recycling facilities and technologies available. Some manufacturers are developing innovative methods to separate and recycle both the aluminum and core components efficiently.

The Recycling Process for Aluminum Sandwich Panels

Recycling aluminum sandwich panels involves several steps, each crucial for maximizing material recovery and minimizing environmental impact:

Collection and Sorting

The first step in recycling aluminum sandwich panels is proper collection and sorting. Construction and demolition sites need to implement effective waste management practices to separate these panels from other materials. This segregation is vital for ensuring the quality of recycled materials and streamlining the recycling process.

Disassembly and Material Separation

Once collected, the panels undergo a disassembly process. Specialized machinery is used to separate the aluminum sheets from the insulation core. This step is critical as it allows for the individual recycling of components:

- Aluminum sheets are sent to aluminum recycling facilities.

- The insulation core is directed to appropriate recycling or waste management facilities based on its composition.

Aluminum Recycling

The aluminum sheets enter the standard aluminum recycling stream. This process involves:

- Shredding the aluminum into small pieces

- Removing any coatings or impurities

- Melting the aluminum in furnaces

- Casting the molten aluminum into ingots or sheets for new applications

This recycled aluminum can be used in new construction projects, including the production of new aluminum sandwich panels, creating a closed-loop recycling system.

Core Material Processing

The fate of the core material depends on its composition:

- Polyurethane may be chemically recycled or used as fuel in energy recovery processes.

- Polystyrene can be melted and reformed into new products or used in the production of synthetic fuel.

- Rock wool can be recycled into new insulation products or used as a soil amendment in agriculture.

Benefits and Challenges of Recycling Aluminum Sandwich Panels

Recycling aluminum sandwich panels offers numerous advantages but also presents certain challenges that the industry is actively addressing:

Environmental Benefits

The recycling of aluminum sandwich panels contributes significantly to environmental conservation:

- Reduced energy consumption compared to producing new aluminum

- Conservation of natural resources, particularly bauxite ore

- Decreased landfill waste and associated environmental impacts

- Lower carbon footprint in construction and renovation projects

Economic Advantages

There are compelling economic reasons to recycle aluminum sandwich panels:

- Creation of a secondary raw materials market, supporting circular economy principles

- Potential cost savings for construction projects using recycled materials

- Job creation in the recycling and material recovery sectors

Technological Challenges

Despite the benefits, recycling aluminum sandwich panels does face some hurdles:

- Developing efficient methods for separating aluminum from insulation materials

- Improving recycling technologies for various types of insulation cores

- Ensuring the quality of recycled materials meets construction industry standards

Logistical Considerations

Effective recycling of aluminum sandwich panels requires addressing logistical challenges:

- Establishing comprehensive collection systems for construction and demolition waste

- Creating a network of specialized recycling facilities capable of processing these panels

- Educating stakeholders about proper disposal and recycling practices

Conclusion

Aluminum sandwich panels embody the principles of sustainable construction, offering not just exceptional performance but also significant recyclability. Their ability to be recycled and repurposed aligns perfectly with global sustainability goals, reducing waste and conserving resources. As recycling technologies advance, the process of reclaiming materials from these panels becomes increasingly efficient, further enhancing their eco-friendly profile. This recyclability, combined with their durability, energy efficiency, and aesthetic versatility, makes aluminum sandwich panels a smart choice for environmentally conscious builders and architects.

At Weifang Sandong Building Materials, we're committed to sustainability and innovation in construction materials. Our aluminum sandwich panels are designed with recyclability in mind, ensuring that your projects not only look great and perform well but also contribute to a more sustainable future. Interested in learning more about our eco-friendly aluminum sandwich panels and how they can benefit your next project? Contact us at info@sdqsc.com for expert advice and solutions tailored to your specific needs.

FAQ

How long do aluminum sandwich panels typically last before needing replacement?

With proper installation and maintenance, aluminum sandwich panels can last 30-50 years, depending on environmental conditions and usage.

Are there any special considerations for recycling painted or coated aluminum sandwich panels?

While painted or coated panels can still be recycled, they may require additional processing to remove surface treatments before recycling.

Can I mix different types of aluminum sandwich panels for recycling?

It's best to sort panels by type if possible, as different core materials may require separate recycling processes.

How does the recycling of aluminum sandwich panels compare to traditional building materials?

Aluminum sandwich panels often have a higher recycling rate and efficiency compared to many traditional materials, contributing to their overall sustainability.

References

1.International Aluminum Institute. (2021). "Aluminium Recycling."

2.European Aluminium. (2022). "Recycling Aluminium: A Pathway to a Sustainable Economy."

3.Waste Management World. (2020). "Innovations in Construction Waste Recycling."

4.Journal of Cleaner Production. (2019). "Life Cycle Assessment of Aluminum Composite Panels."

5.Building and Environment. (2021). "Sustainable Building Materials: Advancements and Challenges."