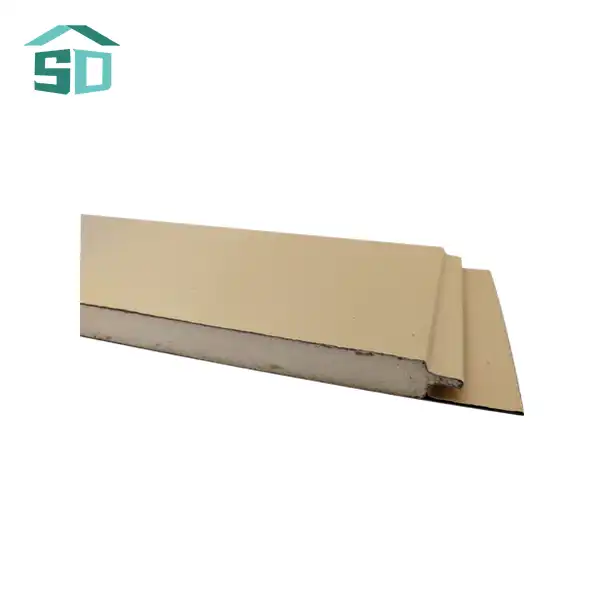

Introducing 10 cm Sandwich Panels: Materials and Construction

The Composition of 10 cm Sandwich Panels

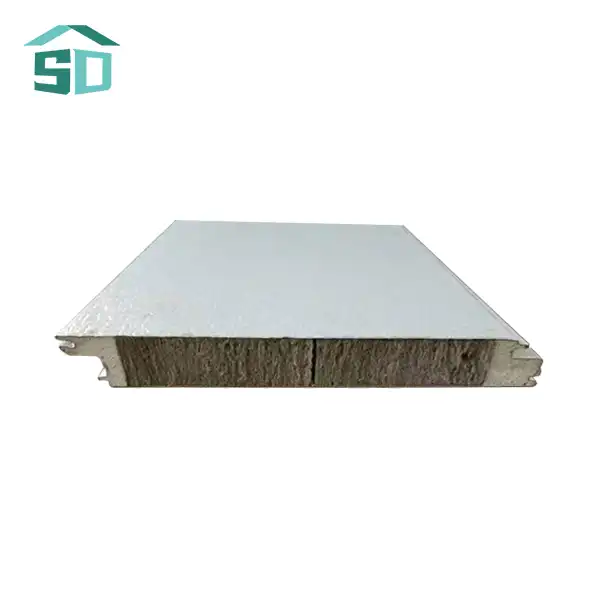

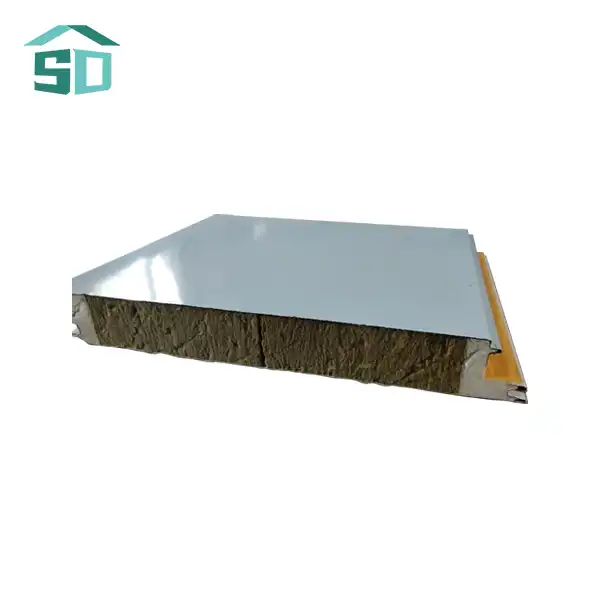

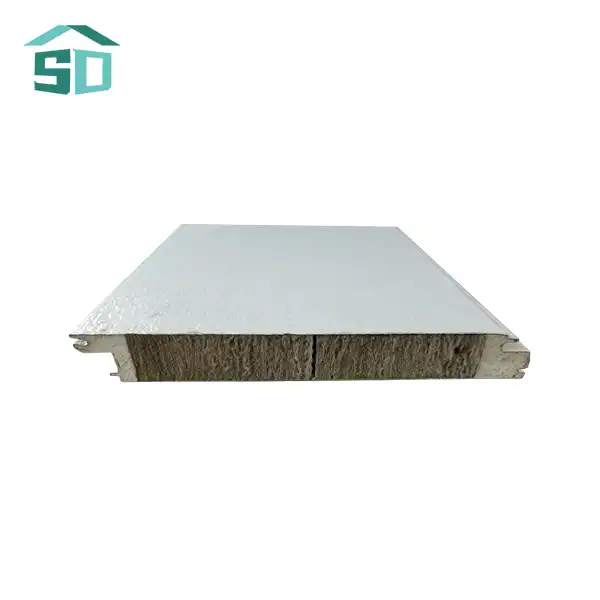

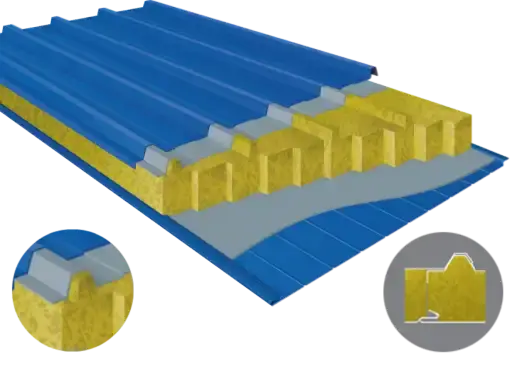

10 cm sandwich panels are versatile building components that have gained popularity in modern construction. These panels consist of three main layers: two outer facings and an insulating core. The outer facings can be made of various materials, with steel and aluminum being the most common choices. The core is typically composed of insulating materials such as polyurethane (PUR), polyisocyanurate (PIR), or mineral wool.

The thickness of 10 cm sandwich panels provides excellent insulation properties, making them ideal for a wide range of applications. 10 cm sandwich panel manufacturers design these panels to offer a balance between structural integrity and thermal performance. The outer facings provide strength and protection against external elements, while the insulating core contributes to the panel's overall thermal efficiency.

Steel vs. Aluminum: Material Properties

When comparing steel and aluminum 10 cm sandwich panels, it's essential to understand the unique properties of each material:

Steel 10 cm Sandwich Panels:

- Higher strength-to-weight ratio

- Excellent durability and impact resistance

- Lower cost compared to aluminum

- Higher thermal conductivity

- More susceptible to corrosion without proper treatment

Aluminum 10 cm Sandwich Panels:

- Lighter weight

- Natural corrosion resistance

- Higher initial cost

- Lower thermal conductivity

- Easier to fabricate and install

Manufacturing Process and Quality Control

The manufacturing process of 10 cm sandwich panels involves several crucial steps to ensure high-quality and consistent products. 10 cm sandwich panel manufacturers utilize advanced production lines and implement strict quality control measures throughout the manufacturing process.

Key steps in the manufacturing process include:

1. Raw material inspection: Rigorous testing of steel coils, aluminum foil, and insulating materials

2. Profiling: Shaping the outer facings to the desired profile

3. Core preparation: Mixing and applying the insulating core material

4. Panel assembly: Bonding the outer facings to the core material

5. Curing: Allowing the panels to set and achieve their final properties

6. Quality control: Comprehensive inspections of product thickness, paint film thickness, mechanical strength, flame retardancy, and overall appearance

Factors Influencing the Price of 10 cm Sandwich Panels

Raw Material Costs: Steel vs. Aluminum

One of the primary factors affecting the price of 10 cm sandwich panels is the cost of raw materials. Steel and aluminum, being the main components of the outer facings, play a significant role in determining the overall price of these panels.

Steel, generally less expensive than aluminum, contributes to the lower price point of steel 10 cm sandwich panels. The global steel market is more extensive and established, leading to more stable prices and greater availability. However, steel prices can fluctuate based on factors such as global demand, trade policies, and production costs.

Aluminum, on the other hand, tends to be more expensive due to its higher production costs and limited global supply. The energy-intensive process of extracting aluminum from bauxite ore contributes to its higher price point. As a result, aluminum 10 cm sandwich panels are typically more expensive than their steel counterparts.

Production Processes and Efficiency

The manufacturing processes for steel and aluminum 10 cm sandwich panels differ in several aspects, which can affect their production efficiency and, consequently, their price. 10 cm sandwich panel manufacturers must optimize their production lines to achieve the best balance between quality and cost-effectiveness.

Steel 10 cm sandwich panels often benefit from more efficient production processes due to the material's properties and the well-established manufacturing techniques in the steel industry. The ability to produce steel panels at higher volumes with lower energy consumption can contribute to their lower overall cost.

Aluminum 10 cm sandwich panels, while more expensive to produce, offer advantages in terms of fabrication and customization. The material's malleability allows for more intricate designs and profiles, which can be beneficial for certain architectural applications. However, this flexibility in design can sometimes lead to longer production times and higher costs.

Advancements in manufacturing technology continue to improve the production efficiency of both steel and aluminum 10 cm sandwich panels. 10 cm sandwich panel manufacturers invest in state-of-the-art equipment and processes to optimize production, reduce waste, and maintain high-quality standards, all of which influence the final price of the panels.

Market Demand and Supply Dynamics

The interplay between market demand and supply significantly impacts the pricing of 10 cm sandwich panels. As the construction industry evolves and embraces more sustainable and efficient building practices, the demand for high-quality insulated panels continues to grow.

Steel 10 cm sandwich panels often experience more stable pricing due to the larger scale of steel production and its widespread use in various industries. The established supply chains and production capabilities for steel panels allow manufacturers to respond more quickly to changes in demand, potentially leading to more competitive pricing.

Aluminum 10 cm sandwich panels, while generally more expensive, may see fluctuations in price based on market trends and specific project requirements. The increasing focus on lightweight, corrosion-resistant materials in certain sectors of the construction industry can drive up demand for aluminum panels, potentially affecting their price.

10 cm sandwich panel manufacturers must carefully navigate these market dynamics to remain competitive while maintaining product quality. Factors such as regional construction trends, regulatory requirements, and emerging technologies all play a role in shaping the demand for different types of sandwich panels, ultimately influencing their pricing.

Long-term Considerations: Cost-effectiveness and Performance

Energy Efficiency and Insulation Properties

When evaluating the cost-effectiveness of 10 cm sandwich panels, it's crucial to consider their long-term energy efficiency and insulation properties. Both steel and aluminum 10 cm sandwich panels offer excellent thermal performance, but there are subtle differences that can impact their overall efficiency.

Steel 10 cm sandwich panels, despite having a higher thermal conductivity than aluminum, can still provide exceptional insulation when combined with high-quality core materials. The thermal break created by the insulating core helps mitigate heat transfer through the steel facings. 10 cm sandwich panel manufacturers often optimize the design of steel panels to maximize their insulation properties, resulting in energy-efficient building envelopes.

Aluminum 10 cm sandwich panels have a natural advantage in terms of thermal performance due to aluminum's lower thermal conductivity. This property makes aluminum panels particularly effective in reducing heat transfer and maintaining stable indoor temperatures. The combination of aluminum facings with advanced insulating cores can result in superior energy efficiency, potentially leading to long-term cost savings through reduced heating and cooling expenses.

Both types of 10 cm sandwich panels contribute significantly to a building's overall energy performance. The choice between steel and aluminum should consider factors such as local climate, building orientation, and specific insulation requirements to determine the most cost-effective solution in terms of long-term energy savings.

Durability and Maintenance Requirements

The durability and maintenance needs of 10 cm sandwich panels play a significant role in their long-term cost-effectiveness. Both steel and aluminum panels offer distinct advantages in this regard, and 10 cm sandwich panel manufacturers continually work to improve the longevity and performance of their products.

Steel 10 cm sandwich panels are known for their exceptional strength and impact resistance. When properly treated and coated, steel panels can withstand harsh environmental conditions and maintain their structural integrity for many years. However, steel panels may require more frequent maintenance and inspection to prevent corrosion, especially in coastal or industrial areas with high salt or chemical exposure.

Aluminum 10 cm sandwich panels offer natural corrosion resistance, making them an excellent choice for buildings in coastal or humid environments. The inherent durability of aluminum reduces the need for frequent maintenance and can contribute to lower long-term costs. Additionally, aluminum panels are less prone to degradation from UV exposure, helping to maintain their appearance and performance over time.

When considering the long-term cost-effectiveness of 10 cm sandwich panels, it's essential to factor in potential maintenance and replacement costs. While aluminum panels may have a higher initial price, their reduced maintenance requirements and longer lifespan can result in lower total ownership costs over the life of the building.

Environmental Impact and Sustainability

In today's construction industry, the environmental impact and sustainability of building materials are becoming increasingly important factors in decision-making processes. 10 cm sandwich panels, whether made of steel or aluminum, offer several environmental benefits, but there are some differences to consider.

Steel 10 cm sandwich panels have the advantage of being highly recyclable. The steel industry has well-established recycling processes, and many steel panels contain a significant percentage of recycled content. This circularity helps reduce the environmental impact of steel panel production and contributes to a more sustainable construction industry.

Aluminum 10 cm sandwich panels also boast excellent recyclability, with aluminum being one of the most recycled materials globally. The production of primary aluminum is energy-intensive, but recycled aluminum requires significantly less energy to process. As a result, aluminum panels with high recycled content can have a lower carbon footprint over their lifecycle.

Both steel and aluminum 10 cm sandwich panels contribute to energy-efficient buildings, reducing the overall environmental impact of structures throughout their operational life. 10 cm sandwich panel manufacturers are increasingly focusing on sustainable production practices and the use of eco-friendly materials in their products to meet the growing demand for green building solutions.

When evaluating the long-term cost-effectiveness of 10 cm sandwich panels, it's important to consider potential environmental regulations, green building certifications, and the growing emphasis on sustainable construction practices. Choosing panels that align with these priorities can lead to long-term benefits in terms of building performance, marketability, and compliance with evolving environmental standards.

Conclusion

In conclusion, the price comparison between steel and aluminum 10 cm sandwich panels involves a complex interplay of factors. While steel panels generally offer a more cost-effective initial solution, aluminum panels present advantages in terms of weight, corrosion resistance, and long-term maintenance. The choice between the two materials should be based on a comprehensive assessment of project requirements, environmental conditions, and long-term performance expectations. By carefully considering factors such as energy efficiency, durability, and sustainability, builders and architects can make informed decisions that balance upfront costs with long-term value. Ultimately, the most cost-effective choice will depend on the specific needs of each project and the priorities of the stakeholders involved.

For expert guidance on selecting the right 10 cm sandwich panel for your project, don't hesitate to reach out to Weifang Sandong Building Materials Co., Ltd. Our team of specialists is ready to assist you in finding the perfect exterior cladding solution that meets your performance requirements and budget constraints. Contact us today at info@sdqsc.com to explore our range of high-quality 10 cm sandwich panels and take the next step towards enhancing your building's performance and aesthetics.

References

1. American Iron and Steel Institute. (2021). Steel Industry Statistics.

2. The Aluminum Association. (2022). Aluminum Sustainability.

3. U.S. Department of Energy. (2021). Building Energy Codes Program.

4. World Steel Association. (2022). Steel's Contribution to a Low Carbon Future.

5. International Energy Agency. (2021). Energy Efficiency in Buildings.