Preparing for Vertical Metal Siding Panel Installation

Site Assessment and Substrate Preparation

Before embarking on the installation of vertical metal siding panels, a thorough site assessment is paramount. This involves evaluating the existing structure, identifying any potential issues, and ensuring the substrate is in optimal condition. The substrate, whether it's wood, concrete, or metal framing, must be clean, dry, and free from any debris or imperfections that could compromise the installation.

Structural integrity is a key consideration. Any existing damage or weakness in the substrate should be addressed and repaired before proceeding. This may involve replacing rotted wood, filling cracks in concrete, or reinforcing metal framing. A solid foundation is crucial for the longevity and performance of the vertical metal siding panels.

Tools and Materials Checklist

Assembling the right tools and materials is essential for a smooth installation process. Here's a comprehensive list of what you'll need:

- Vertical metal siding panels

- Measuring tape and level

- Chalk line

- Power drill with appropriate bits

- Metal snips or circular saw with metal-cutting blade

- Fasteners (screws or nails designed for metal siding)

- Sealant and caulking gun

- Safety equipment (gloves, safety glasses, hearing protection)

- Ladder or scaffolding

Having these tools and materials ready will streamline the installation process and help ensure a professional result.

Understanding Panel Specifications

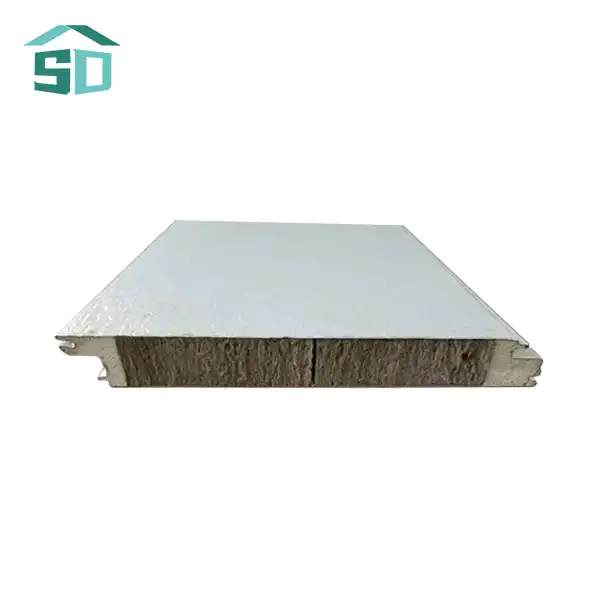

Familiarizing yourself with the specific characteristics of the vertical metal siding panels is crucial. This includes understanding the panel dimensions, thickness, and interlocking mechanisms. Our panels are available in customized sizes to meet project requirements, with common dimensions including 12" x 96" and 24" x 120". Thickness options typically range from 24 to 28 gauge, offering varying levels of durability and weight.

It's also important to note the insulation materials used, such as polyurethane, polystyrene, rock wool, or glass wool, as these affect the panel's thermal and acoustic properties. Understanding these specifications will guide you in making informed decisions during the installation process.

Step-by-Step Installation Process

Measuring and Layout

Accurate measurements are the foundation of a successful installation. Begin by measuring the entire area where the vertical metal siding panels will be installed. Use a chalk line to mark reference points and ensure straight lines. Pay special attention to corners, windows, and doors, as these areas may require custom cuts. Create a detailed layout plan, considering the panel sizes and any patterns or designs you wish to incorporate. This planning stage is crucial for minimizing waste and ensuring a cohesive, aesthetically pleasing result.

Panel Cutting and Fitting

With your layout plan in hand, proceed to cut the vertical metal siding panels as needed. Use metal snips for small cuts or a circular saw with a metal-cutting blade for longer cuts. Always wear appropriate safety gear, including gloves and eye protection, when cutting metal panels. When fitting panels around obstacles like windows or vents, take precise measurements and make careful cuts. It's often helpful to create templates for complex shapes to ensure accuracy.

Securing Panels and Interlocking

Begin the installation process at the bottom of the wall, working your way up. This approach allows for proper water drainage and ensures each panel interlocks securely with the one below it. Use the appropriate fasteners, such as screws or nails designed specifically for metal siding, to secure the panels. Pay close attention to the interlocking mechanisms of the panels. Proper interlocking is crucial for weather resistance and overall performance. Each panel should fit snugly with its neighbors, creating a seamless appearance and a watertight seal.

Finishing Touches and Quality Assurance

Sealing and Weatherproofing

Once all panels are in place, focus on sealing and weatherproofing. Apply high-quality sealants to joints, corners, and any areas where water infiltration might occur. This step is critical for preventing moisture damage and ensuring the longevity of both the siding and the underlying structure. Pay special attention to areas around windows, doors, and any penetrations in the siding. These are common weak points and require extra care to ensure proper sealing.

Aesthetic Considerations

The final appearance of your vertical metal siding panels is a testament to the quality of the installation. Take time to step back and assess the overall look. Check for any misalignments or gaps that might detract from the aesthetic appeal. If you've chosen custom colors or finishes for your panels, ensure that any touch-ups or corrections are made using matching materials. Our panels are available in a range of standard colors including White, Black, Gray, and Blue, with custom color options available to suit your specific design needs.

Post-Installation Inspection

A careful post-installation review is pivotal to guarantee the quality and astuteness of the work. Check each board for appropriate arrangement, secure securing, and rectify interlocking. Confirm that all seals and weatherproofing measures are in put and successful. This assessment ought to moreover incorporate a audit of the building's in general appearance, guaranteeing that the vertical metal siding boards upgrade the structure's tasteful as planning. Address any issues expeditiously to avoid potential issues down the line.

Conclusion

The installation of vertical metal siding panels requires careful planning, precise execution, and attention to detail. By following these guidelines and leveraging the high-quality products offered by Weifang Sandong Building Materials Co., Ltd., you can achieve a durable, energy-efficient, and visually striking exterior for your building project. For more information on our vertical metal siding panels and other exterior cladding solutions, please don't hesitate to contact us at info@sdqsc.com.