Unveiling the Core Components of Rockwool Sandwich Panels

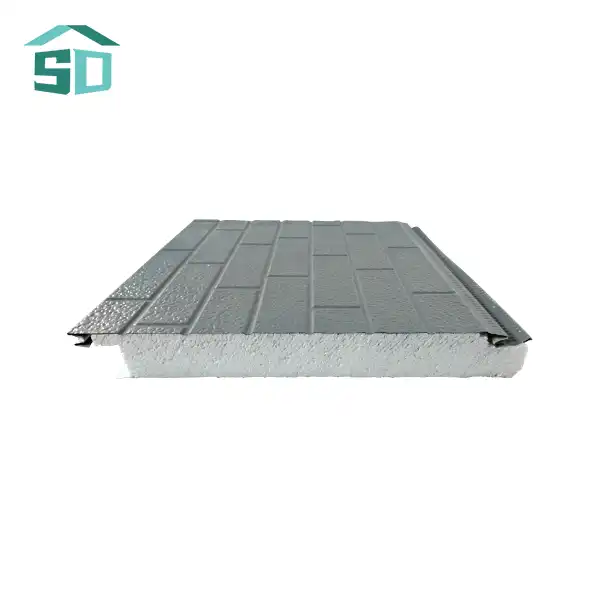

Material Composition: The Foundation of Strength

Rockwool sandwich panels are a testament to ultramodern engineering, combining robust accoutrements to produce a product that excels in both form and function. At their core, these panels use sword or aluminum as the primary structural factors. This metallic foundation provides the necessary strength and continuity to repel colorful environmental stressors, icing the life of the structure envelope.

The choice between steel and aluminum is often dictated by the specific requirements of the project. Steel offers superior strength and is often the go-to choice for industrial applications where rigidity is paramount. Aluminum, on the other hand, provides a lightweight alternative that's particularly beneficial in projects where weight reduction is a priority, such as in high-rise buildings or renovations of older structures with limited load-bearing capacity.

Rockwool Insulation: The Heart of Thermal Efficiency

The defining feature of rockwool sandwich panels is, of course, the rockwool insulation at their core. This mineral wool insulation is derived from natural, abundant raw materials, primarily basalt rock and recycled content. The manufacturing process involves melting these materials and spinning them into fibers, creating a dense mat of insulation with exceptional thermal properties.

Rockwool insulation offers a unique combination of benefits that set it apart from other insulation materials:

- Superior thermal performance, maintaining consistent R-values across a wide temperature range

- Excellent sound absorption properties, contributing to improved acoustic comfort in buildings

- Inherent fire resistance, with a Class A1 fire rating that enhances building safety

- Moisture resistance, preventing mold growth and maintaining its insulative properties even in damp conditions

- Dimensional stability, resisting warping or sagging over time

These characteristics make rockwool an ideal choice for sandwich panels, offering a comprehensive solution for thermal insulation, fire safety, and acoustic comfort in a single product.

Surface Treatments: The Aesthetic and Protective Layer

The outer layers of rockwool sandwich panels are not merely structural elements; they also serve as the aesthetic face of the building and provide crucial protection against environmental factors. These panels can be customized with a variety of surface treatments to meet both functional and design requirements:

Coated Surfaces: A protective coating can be applied to enhance resistance against corrosion, UV radiation, and chemical exposure. This is particularly beneficial in industrial environments or coastal areas where exposure to harsh conditions is a concern.

Painted Finishes: A wide array of colors is available through painting, allowing architects and designers to realize their creative visions. The ability to customize panel colors using RAL color codes offers virtually limitless aesthetic possibilities, enabling seamless integration with any architectural style or brand identity.

Anodized Aluminum: For panels with aluminum facing, anodizing is an option that provides both aesthetic appeal and enhanced durability. This electrochemical process creates a hard, porous oxide layer on the aluminum surface, which can be dyed in various colors while improving corrosion resistance and wear resistance.

These surface treatments not only contribute to the visual appeal of the building but also play a crucial role in protecting the panels and extending their lifespan, ensuring that the investment in rockwool sandwich panels pays dividends for years to come.

Dimensional Specifications: Tailoring to Project Needs

Standard and Custom Panel Sizes

Rockwool sandwich panels are available in a range of standard sizes to accommodate various building designs and construction requirements. The typical panel size of 1200mm x 3000mm offers a balance between manageable handling and efficient coverage. This standardization facilitates streamlined production processes and simplifies installation procedures, contributing to cost-effectiveness and reduced construction timelines.

However, the true versatility of rockwool sandwich panels lies in their customizability. Manufacturers often offer the flexibility to tailor panel dimensions to meet specific project needs. This adaptability is invaluable in scenarios where non-standard sizes are required, such as:

- Retrofitting existing structures with unique architectural features

- Accommodating irregular building shapes or curved facades

- Optimizing material use and minimizing waste in large-scale projects

- Meeting specific design requirements for aesthetic or functional purposes

The ability to customize panel sizes ensures that rockwool sandwich panels can be seamlessly integrated into virtually any building design, maximizing their utility and aesthetic impact.

Thickness Options: Balancing Insulation and Space Efficiency

The thickness of rockwool sandwich panels is a critical specification that directly impacts their insulative performance and overall system efficiency. Standard thickness options typically range from 50mm to 150mm, with common increments including:

- 50mm: Suitable for applications with moderate insulation requirements or where space is at a premium

- 75mm: Offers enhanced insulation while maintaining a relatively slim profile

- 100mm: Provides robust insulation performance for most commercial and residential applications

- 150mm: Delivers superior insulation for high-performance buildings or extreme climate conditions

The choice of panel thickness is influenced by several factors:

- Local building codes and energy efficiency standards

- Climate conditions and desired thermal performance

- Structural considerations and load-bearing requirements

- Cost considerations and return on investment calculations

By offering a range of thickness options, manufacturers enable architects and engineers to fine-tune the balance between insulation performance and spatial efficiency, ensuring that the chosen rockwool sandwich panels meet both regulatory requirements and project-specific goals.

Weight Considerations: Implications for Design and Installation

The weight of rockwool sandwich panels is an often-overlooked specification that can have significant implications for building design, transportation, and installation processes. The overall weight of a panel is determined by its dimensions, the density of the rockwool core, and the thickness of the metal facings.

Panels with steel facings typically weigh more than those with aluminum facings, which can impact:

- Structural design: Heavier panels may require additional support structures

- Transportation costs: Weight affects shipping expenses and logistics planning

- Installation methods: Lighter panels may allow for easier manual handling, while heavier panels might necessitate mechanical lifting equipment

- Building load calculations: The cumulative weight of panels must be factored into overall building design

Understanding the weight specifications of rockwool sandwich panels is crucial for project planning and execution. It allows for accurate structural calculations, efficient logistics planning, and appropriate allocation of resources during the installation phase. By considering these factors early in the design process, project teams can optimize their use of rockwool sandwich panels, ensuring a smooth and cost-effective implementation.

Performance Metrics: Quantifying Excellence

Thermal Insulation: R-Values and U-Values Demystified

The primary function of rockwool sandwich panels is to provide superior thermal insulation, and their performance in this regard is quantified through R-values and U-values. These metrics are essential for understanding the panel's effectiveness in resisting heat flow and maintaining energy efficiency.

R-Value: This measure represents the thermal resistance of the panel. Higher R-values indicate better insulation performance. The R-value of rockwool sandwich panels varies depending on the thickness of the insulation layer and the specific composition of the rockwool. Typically, R-values for these panels range from R-3 to R-6 per inch of thickness, allowing for customization to meet specific climate and building code requirements.

U-Value: The U-value is the inverse of the R-value and represents the rate of heat transfer through the panel. Lower U-values indicate better insulation performance. Rockwool sandwich panels often achieve U-values as low as 0.15 W/m²K for thicker panels, making them excellent choices for energy-efficient building envelopes.

These thermal performance metrics are crucial for:

- Meeting or exceeding local energy codes and standards

- Calculating potential energy savings and return on investment

- Designing high-performance, sustainable buildings

- Optimizing HVAC system sizing and efficiency

Fire Resistance: Class A1 Rating Explained

One of the standout features of rockwool sandwich panels is their exceptional fire resistance, as evidenced by their Class A1 fire rating. This classification, based on the European standard EN 13501-1, represents the highest level of fire safety for construction materials.

The Class A1 rating indicates that the material:

- Does not contribute to fire growth or spread at any stage of a fire

- Produces no smoke or flaming droplets/particles

- Has zero or insignificant combustible content

This superior fire performance is attributed to the inherent properties of rockwool, which is made from stone and can withstand temperatures up to 1000°C (1832°F) without melting. The fire-resistant qualities of rockwool sandwich panels contribute significantly to building safety by:

- Containing fires within compartments, preventing rapid spread

- Providing valuable time for occupant evacuation and firefighter intervention

- Reducing the risk of structural collapse due to fire exposure

- Minimizing property damage and potential loss of life

The Class A1 fire rating of rockwool sandwich panels makes them an ideal choice for applications where fire safety is paramount, such as high-rise buildings, industrial facilities, and public structures.

Acoustic Performance: Sound Transmission Class (STC) Ratings

While often overlooked in favor of thermal and fire performance, the acoustic properties of rockwool sandwich panels are a significant advantage in many applications. The fibrous structure of rockwool is inherently sound-absorptive, making these panels excellent for controlling noise transmission between spaces.

The acoustic performance of rockwool sandwich panels is typically measured using the Sound Transmission Class (STC) rating. This single-number rating provides an estimate of the panel's ability to reduce sound transmission across a range of frequencies. Higher STC ratings indicate better sound insulation properties.

Rockwool sandwich panels can achieve STC ratings ranging from 30 to 50 or higher, depending on the panel thickness and specific configuration. This level of acoustic performance is beneficial for:

- Creating quiet, productive work environments in office buildings

- Enhancing privacy and comfort in multi-family residential structures

- Reducing noise pollution in industrial settings

- Improving the acoustic quality of performance spaces and auditoriums

The combination of thermal insulation, fire resistance, and acoustic performance makes rockwool sandwich panels a comprehensive solution for building envelopes, addressing multiple performance criteria with a single product.

Conclusion

Rockwool sandwich panels represent a pinnacle of building material innovation, offering a unique combination of thermal efficiency, fire safety, and acoustic performance. Their key specifications, from material composition and dimensional flexibility to performance metrics, demonstrate their versatility and effectiveness in modern construction. As the building industry continues to evolve towards more sustainable and high-performance solutions, rockwool sandwich panels stand out as a product that meets both current needs and future challenges. For those seeking to enhance their building projects with these advanced materials, further information and customized solutions are available. To explore how rockwool sandwich panels can benefit your specific project, please contact us at info@sdqsc.com.