The Science Behind Steel PU Sandwich Panels' Fire Resistance

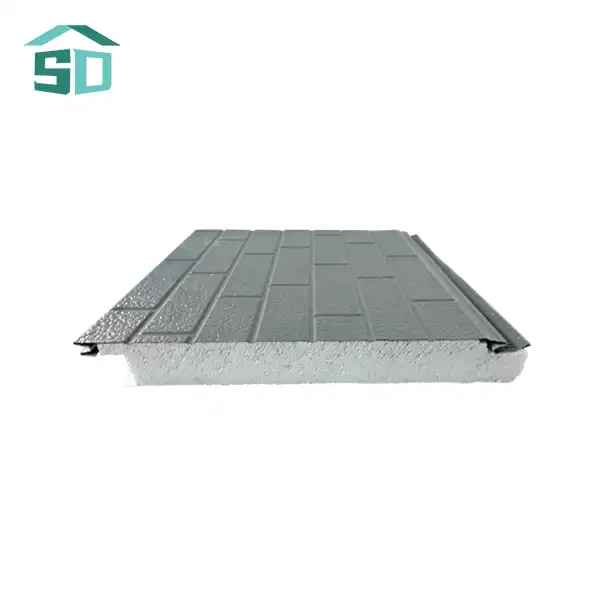

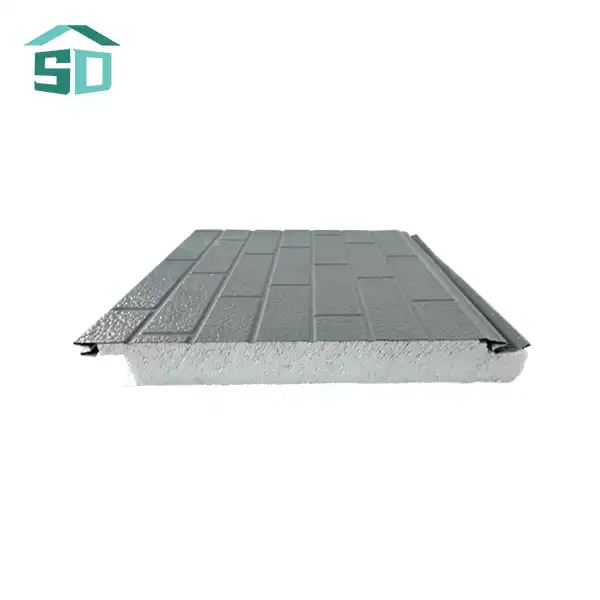

Steel PU sandwich panels are engineered to provide superior fire resistance through a combination of materials and design. The outer steel layers act as a primary barrier against flame spread, while the polyurethane core is formulated to resist ignition and slow down heat transfer. This synergy creates a formidable defense against fire propagation.

Material Composition and Fire Rating

The fire-resistant properties of steel PU sandwich panels stem from their unique composition. The steel facings are inherently non-combustible, providing an initial layer of protection. The polyurethane foam core, while insulative, is treated with fire-retardant additives that significantly enhance its resistance to ignition and flame spread.

These panels undergo rigorous testing to achieve their Class A fire rating, which is the highest classification for building materials. This rating indicates that the panels have demonstrated excellent performance in fire tests, including low flame spread and minimal smoke development. The Class A rating ensures compliance with stringent building regulations and provides peace of mind for property owners and occupants alike.

Thermal Barrier Effect

One of the key features that contribute to the fire resistance of steel PU sandwich panels is their thermal barrier effect. The polyurethane core, with its closed-cell structure, acts as an effective insulator against heat transfer. This insulation not only improves energy efficiency but also plays a crucial role in fire scenarios.

During a fire, the insulating properties of the PU core help to slow down the temperature rise on the unexposed side of the panel. This thermal barrier effect can be critical in providing additional time for evacuation and fire suppression efforts. The panels' ability to maintain their structural integrity under high temperatures further enhances their fire-resistant capabilities.

Comparative Analysis: Steel PU Sandwich Panels vs. Traditional Materials

To truly understand the fire-resistant qualities of steel PU sandwich panels, it's essential to compare them with traditional building materials. This comparison highlights the advantages and potential limitations of steel PU sandwich panels in fire safety applications.

Steel PU Sandwich Panels vs. Concrete

Concrete is well-known for its fire-resistant properties, but steel PU sandwich panels offer several advantages. While concrete is heavy and requires significant construction time, steel PU panels are lightweight and can be installed quickly. The insulation properties of steel PU panels often surpass those of concrete, providing better energy efficiency.

In terms of fire resistance, both materials perform well. However, steel PU sandwich panels offer more consistent performance across their entire surface area, whereas concrete can develop cracks over time that may compromise its fire-resistant properties. Additionally, the ability to customize steel PU panels with different thicknesses (50mm, 75mm, 100mm) allows for tailored fire resistance to meet specific project requirements.

Steel PU Sandwich Panels vs. Traditional Steel Structures

Compared to traditional steel structures, steel PU sandwich panels offer enhanced fire resistance. While steel alone is non-combustible, it can lose structural integrity at high temperatures. The polyurethane core in sandwich panels acts as an insulator, protecting the steel from rapid temperature increases and maintaining structural stability for a longer period during a fire event.

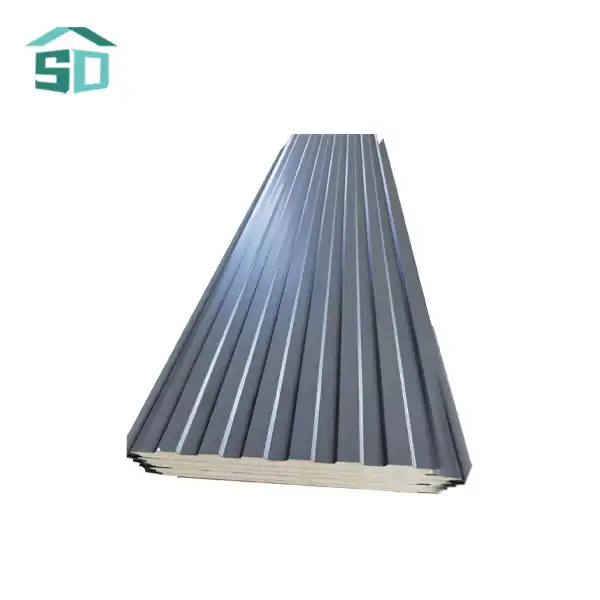

Moreover, steel PU sandwich panels provide a complete building envelope solution, combining structural support, insulation, and fire resistance in a single product. This integrated approach can lead to faster construction times and improved overall building performance compared to traditional steel frame buildings that require separate insulation and fire-proofing measures.

Beyond Fire Resistance: Additional Benefits of Steel PU Sandwich Panels

While fire resistance is a crucial aspect of steel PU sandwich panels, these versatile building materials offer a range of additional benefits that make them an attractive option for various construction projects.

Energy Efficiency and Insulation

The high-density polyurethane core of steel PU sandwich panels provides exceptional thermal insulation. This insulation capability translates into significant energy savings for heating and cooling, making buildings more environmentally friendly and cost-effective to operate. The panels' ability to create an efficient heat and cold barrier is particularly valuable in extreme climates, where maintaining consistent indoor temperatures is challenging.

Furthermore, the excellent insulation properties contribute to sound dampening, creating more comfortable interior environments in noisy urban or industrial settings. This dual benefit of thermal and acoustic insulation makes steel PU sandwich panels an ideal choice for a wide range of applications, from residential buildings to industrial facilities.

Durability and Weather Resistance

Steel PU sandwich panels are engineered to withstand harsh environmental conditions. The steel facings provide robust protection against impacts and wear, while the polyurethane core resists moisture penetration. This combination results in a building material that maintains its structural integrity and appearance over time, even when exposed to challenging weather conditions.

The panels' resistance to corrosion is further enhanced by protective coatings applied to the steel surfaces. This added layer of defense against rust and degradation ensures long-term performance and reduces maintenance requirements. For coastal areas or industrial environments where corrosion is a significant concern, steel PU sandwich panels offer a durable and low-maintenance solution.

Versatility in Design and Application

One of the standout highlights of steel PU sandwich boards is their flexibility in plan and application. Accessible in a wide extend of colors and wraps up, these boards can be customized to meet particular tasteful prerequisites. The capacity to select from the RAL color chart permits planners and creators to make outwardly striking buildings that complement their environment or make a striking statement.

The panels' lightweight nature and ease of establishment make them appropriate for different development ventures, from modern builds to redesigns. Their versatility amplifies to diverse divisions, counting private, commercial, mechanical, and indeed transportation. Whether utilized for outside dividers, material, or insides allotments, steel PU sandwich boards offer a adaptable arrangement that can be custom-made to assorted building dreams and useful needs.

Conclusion

Steel PU sandwich panels represent a significant advancement in building materials, offering a compelling combination of fire resistance, energy efficiency, and versatility. While they may not be the singular "ultimate" fire-resistant solution for every scenario, their comprehensive set of benefits makes them a top contender in modern construction practices. As the industry continues to prioritize safety, sustainability, and performance, steel PU sandwich panels are well-positioned to play a crucial role in shaping the future of building design and construction.

For those interested in exploring the potential of steel PU sandwich panels for their projects, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. To learn more about our exterior cladding and facade solutions, including steel PU sandwich panels, please contact us at info@sdqsc.com. Our team is ready to assist you in finding the perfect solution for your construction needs, ensuring safety, efficiency, and aesthetic appeal in your next project.