Decorative exterior wall panelsthat are fire-rated are a big step forward in modern building safety because they look good and protect against fire. In an emergency, these specialized covering systems work much better than regular siding because they use fire-resistant materials and are designed for treatment. Unlike regular artistic outdoor wall panels, fire-rated versions go through a lot of tests to make sure they meet ASTM E119 and UL standards. This makes sure they can handle high temperatures without losing their shape. More and more, building rules across the US require outdoor materials that are resistant to fire. This is especially true in areas that are prone to wildfires and densely populated cities, where fire safety directly affects people's safety and the safety of property.

Understanding Fire-Rated Exterior Cladding Technology

Fire-rated outdoor wall systems use advanced material science to make them more fire-resistant without limiting the ways they can be designed. The main technology uses mineral fiber mixes, chemicals that stop fires, and special protective layers that work together to stop the flame from spreading and lower heat transfer. Modern fire-rated panels use several important technological advances to make them safer:

- Mineral Wool Core Construction: High-density mineral wool provides exceptional fire resistance, withstanding temperatures exceeding 2000°F while maintaining structural stability. This core material effectively insulates against heat transfer, protecting internal building components during fire events. The mineral composition resists combustion and prevents toxic gas emission, making it ideal for occupied structures.

- Intumescent Coating Systems: Advanced chemical coatings expand when exposed to heat, creating a protective char layer that shields underlying materials. These coatings activate at specific temperature thresholds, providing automatic fire protection without manual intervention. The expansion process seals gaps and joints, preventing flame penetration through panel connections.

- Non-Combustible Metal Substrates: Aluminum and steel substrates offer inherent fire resistance while supporting decorative finishes. These materials maintain structural integrity under extreme heat, preventing panel failure and collapse. Metal substrates also facilitate efficient heat dissipation, reducing overall fire risk.

When you put these technical elements together, you get outdoor covering systems that meet strict fire safety standards and give you the design options that modern architecture demands. When you combine several fire-resistant technologies, you get full safety in a wide range of fire risk situations.

Material Options and Performance Characteristics

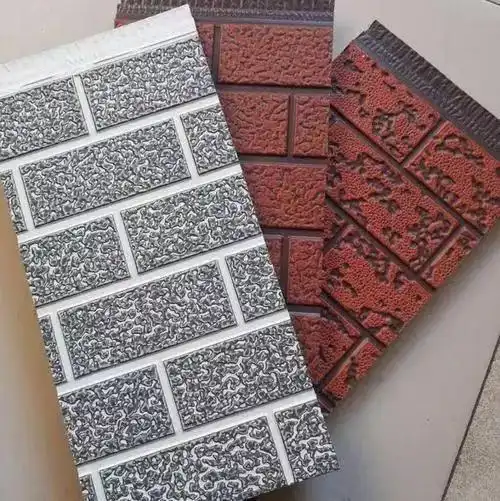

Your choice of fire-rated exterior materials will depend on the needs of the job, the weather, and your personal taste in style. Each type of material has its own benefits when it comes to fire safety, longevity, and style options. One of the most flexible fire-rated choices on the market today is fiber cement walls. Portland cement, sand, and cellulose fibers are mixed together in these composite materials to make walls that won't catch fire and give you a lot of design options. Fiber cement gets Class A fire ratings and can stand up to direct flames for a long time.

The material can be finished in a number of ways, such as with paint, stain, or pattern coats. This lets builders achieve a wide range of aesthetic goals without reducing safety. Fire-resistant bases in metal composite panels make them very resistant to fire and give modern architecture a sleek look. The face sheets of these systems are usually made of metal and are attached to mineral-filled polymer bases that don't burn or spread heat. The metal surfaces are better at withstanding weather and don't need much upkeep over their useful life.

Modern powder coating technologies let you choose from almost infinite color and pattern choices while keeping the fire performance properties. Mineral wool cores built intoDecorative exterior wall panels make them both fire-resistant and good for building structures. These screens have fire protection scores of up to four hours and do a great job of keeping heat in. The constant insulation layer stops thermal bridging, which lowers energy use and raises comfort levels. Because they are easy to install, these panels are great for large-scale business and industrial uses.

High-pressure laminate panels are another fire-resistant option that can be used in a wide range of ways. These items have artistic top layers glued to fire-resistant bases, making them look like real wood, stone, and cloth. During the making process, fire-retardant resins are used to stop the sparks from starting and the flames from spreading. HPL screens keep their colors even when they are exposed to UV light and don't let water or living things grow on them.

Installation Standards and Fire Safety Integration

For Decorative exterior wall panels to keep their fire-resistant qualities, they must be installed correctly. To make sure there is full fire protection, installation methods must include attaching panels, closing joints, and integrating with other building systems. Installing a fire-rated panel starts with making sure the base is ready and using the right connection methods. Mounting systems need to be able to handle heat growth while still keeping panels in place during a fire. To avoid heat bridges and possible breakdown points, mechanical connections need to be carefully chosen.

Continuous support systems spread loads out evenly and keep panels from warping when temperatures change. Joint sealing is an important part of making sure that a system is fire-safe. Fire-rated seals and sealants keep flames and smoke from getting through panel connections. These materials have to stay flexible and stick together in very cold and very hot temperatures, and they also have to remain stable when exposed to UV light and changing weather. Joints that are properly designed can move with the building without compromising the fire shields.

For fire protection systems to work together, the outside covering and sprinkler systems, fire dampers, and emergency air gear need to work together. Installing panels must not get in the way of the fire department's entry or emergency exits. Leaving enough space around holes and penetrations stops fires from spreading through weak spots in the building skin. For quality assurance during installation, the orientation of the panels, the placement of the fasteners, and the integrity of the joint seals must be checked frequently. Documenting the construction process and material certifications helps make sure that building codes are followed and that warranties are honored. Some tests that may be done after installation are thermal imaging and checking the stability of the joints to make sure the fire shield stays in place.

Procurement Strategies for Fire-Rated Exterior Systems

To successfully buy fire-rated artistic Decorative exterior wall panels, you need to carefully look at the skills of the seller, the certifications of the products, and the specific needs of the project. Technical requirements, release times, and long-term support services should all be part of the buying process. Verification of product approval is the basis of careful buying. The fire ratings have to meet the standards of building rules and insurance companies. Listings on UL, test reports from ASTM, and review reports from ICC-ES all give concrete performance data that can be used to make buying choices.

Independent proof of fire protection claims is made possible by third-party testing labs. When evaluating a supplier, you should look at their production skills, quality control methods, and expert support services. Manufacturers that have been around for a while usually offer full product warranties and help with fitting from professionals. Delivery plans and project management are affected by the amount of goods that can be made and how they are distributed geographically.

Financial security and the image of the business affect how long parts will be available and how well service will be provided. Projects can reach certain performance and appearance goals when they can be customized. Leading makers offer a wide range of colors, textures, and panel sizes to meet the needs of architects. Custom manufacturing services can work with unique design aspects while still meeting fire safety standards. Prior to making large-scale purchases, sample panels let you check the look and quality.

When there are tight deadlines for building big projects, supply chain issues become even more important. Manufacturing wait times, shipping operations, and managing supplies all have an effect on how long it takes to finish a job. Reliable providers make sure they have enough production capacity and use quality control methods to avoid delays and problems.

Real-World Applications and Performance Data

Exterior wall panels that are fire-rated have been shown to work in a wide range of building kinds and locations. Performance data from real sites tells us a lot about how long something will last and how safe it is in case of fire. Commercial office buildings are a big place where fire-rated cladding systems are used. Mineral wool insulated panels have been used successfully in recent projects in California and Texas to meet stricter fire rules and LEED certification goals. These works show how materials that are safe around fire can help with both safety and environmental goals.

Building owners say that tenants are happier and their insurance fees have gone down because they feel safer. Because people in healthcare buildings can't move around easily and the business needs to run smoothly, it needs extra strong fire protection. Fiber cement walls that are fire-rated have worked well in hospitals and senior living facilities where people may not be able to easily leave. Because these materials can't catch fire, they keep fires from spreading and keep harmful gases from being released during crises.

Even in areas with a lot of traffic, maintenance needs are kept to a minimum. Fire-rated outdoor systems protect kids and workers and work with a variety of architectural styles in educational buildings. Dormitories for college students and schools for grades K–12 have successfully added artistic fire-rated walls that meet safety standards without looking too official. These systems last a long time, which means they don't need as much upkeep over time and still protect against fire.

In areas prone to wildfires, more fire-rated outdoor materials are being used by homeowners who want to protect their homes better. Class A rated roofing systems have been used in residential projects in Colorado, California, and Australia to show that they can help protect buildings from wildfires. Insurance companies are becoming more aware of these systems and are offering lower premiums and better coverage as a result.

Conclusion

Fire-rated decorative exterior wall panels represent an essential evolution in building safety technology, providing comprehensive fire protection without sacrificing architectural creativity. The integration of advanced materials science, rigorous testing standards, and innovative manufacturing techniques has created cladding systems that meet the most demanding safety requirements while offering unlimited design possibilities. As building codes continue emphasizing fire safety and climate change increases wildfire risks, these specialized panels become increasingly valuable for protecting lives and property. Professional procurement strategies that prioritize certified performance, reliable suppliers, and comprehensive technical support ensure successful project outcomes and long-term building safety.

FAQs

What fire resistance ratings are available for decorative exterior wall panels?

Fire-rated decorative exterior wall panels are available with resistance ratings ranging from 1 to 4 hours, depending on the specific material composition and testing standards. Most commercial applications utilize panels with 1-2 hour ratings, while high-risk buildings may require 3-4 hour systems. These ratings indicate how long the panel system can resist fire penetration and maintain structural integrity during standardized fire exposure tests.

How do fire-rated panels compare in cost to conventional exterior cladding?

While fire-rated exterior panels typically carry a premium of 15-25% over conventional materials, the total cost of ownership often favors fire-rated systems due to reduced insurance premiums, lower maintenance requirements, and enhanced building value. Many building codes now mandate fire-resistant materials in certain applications, making the cost comparison less relevant than code compliance and safety benefits.

Can fire-rated exterior panels achieve the same aesthetic variety as standard decorative options?

Modern fire-rated panels offer extensive design flexibility with hundreds of color options, texture patterns, and finish treatments available. Advanced manufacturing techniques enable realistic wood grain, stone texture, and metallic appearances while maintaining fire-resistant properties. Custom fabrication services can accommodate specific architectural requirements without compromising safety performance.

Partner with Weifang Sandong Building Materials Co., Ltd. for Superior Fire-Rated Solutions

Work with Weifang Sandong Building Materials Co., Ltd. at no cost. For Better Fire-Rated Options, our company, Weifang Sandong Building Materials Co., Ltd., Stands as a reliable provider of artistic outdoor wall panels, providing a wide range of fire-rated siding options that meet the strictest safety and style standards. Our wide range of products includes mineral wool insulation panels, fiber cement systems, and metal composite choices that are very resistant to fire and give you a lot of design options.

Our production agreements with top companies like Baosteel, Akzo Nobel, and KCC guarantee that all of our products will have high-quality materials and work at the same level. In modern factories, cutting-edge quality control systems keep an eye on things like covering integrity, thickness tolerances, and fire performance features as they are being made. ASTM, UL, and foreign fire safety standards are met through thorough testing methods.

As part of their technical support services, projects are given design advice, samples, and installation instructions to make sure they go well. Our tech team works with builders and contractors to make sure that the panels they choose are the best ones for each job and the surroundings. Custom construction lets you meet the specific needs of your design while still meeting approved fire performance levels. Customers in more than 30 countries are served by global transportation networks that offer reliable shipping plans and helpful customer service.

Whether you're building something new or fixing something up, our team offers one-stop supply options that make buying things easier and make the job less complicated. A lot of warehouse management makes sure that materials are available for both regular and fast shipping needs. Experience the difference that professional-grade fire-rated exterior wall systems can make for your next project. Contact us at info@sdqsc.com to discuss your specific requirements and receive detailed product information tailored to your application needs.

References

1. National Fire Protection Association. "NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components." 2019 Edition.

2. American Society for Testing and Materials. "ASTM E119-20: Standard Test Methods for Fire Tests of Building Construction and Materials." Annual Book of ASTM Standards, Volume 04.07.

3. International Code Council. "International Building Code Chapter 14: Exterior Walls and Chapter 26: Fire-Resistance-Rated Construction." 2021 Edition.

4. Underwriters Laboratories. "Fire Resistance Directory: Exterior Wall and Partition Assemblies." Volume 2, 2023 Edition.

5. Factory Mutual Global. "Property Loss Prevention Data Sheet 1-57: Exterior Insulated Wall and Roof Assemblies." September 2022 Revision.

6. Building and Construction Authority Singapore. "Fire Safety Guidelines for External Wall Cladding Systems." Technical Publication Series, 2021 Update.

.webp)

.webp)

Enhancing Panel Longevity Through Design and Material Choices

Enhancing Panel Longevity Through Design and Material Choices.webp)

.webp)

.webp)

.webp)

.webp)

.webp)