The Science Behind Fireproof Insulation Panels

Material Composition and Fire Resistance

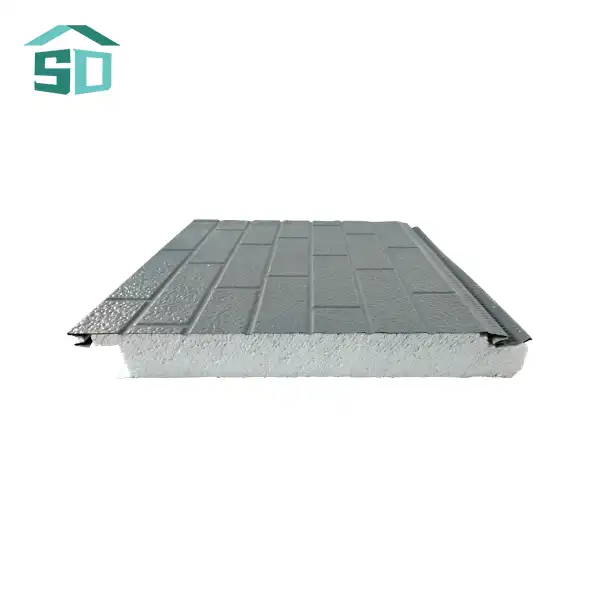

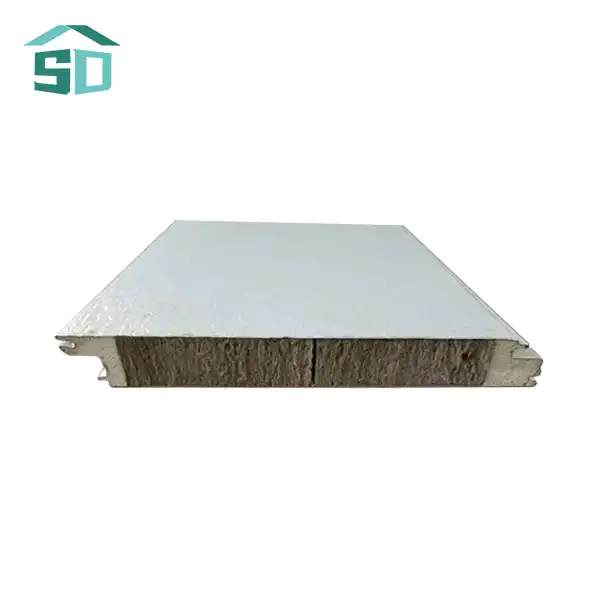

At the core of fireproof insulation panels lies a carefully engineered combination of materials that work in synergy to provide exceptional fire resistance. These panels typically consist of a robust outer layer made from aluminum, steel, or stainless steel, which acts as the first line of defense against fire. The inner core is composed of high-performance insulation materials such as polyurethane, polystyrene, rock wool, or glass wool, each chosen for its specific thermal and acoustic properties.

The fire resistance of these panels is further enhanced through advanced surface treatments like specialized coatings, paints, or anodizing processes. These treatments not only improve the panels' ability to withstand high temperatures but also contribute to their overall durability and aesthetic appeal. The result is a product that meets stringent fire safety standards, with fire ratings ranging from A1 to B2 according to EN 13501-1, providing peace of mind for builders and occupants alike.

Thermal Insulation Properties

One of the primary functions of fireproof insulation panels is to provide superior thermal insulation. The materials used in these panels are selected for their low thermal conductivity, which effectively minimizes heat transfer between the interior and exterior of a building. This exceptional insulation capability translates into significant energy savings for heating and cooling, making fireproof insulation panels an eco-friendly choice for sustainable construction projects.

The thermal performance of these panels is further enhanced by their design, which often includes air gaps or reflective layers to improve their insulating properties. With options for varying thicknesses - typically 50mm, 75mm, or 100mm - builders can choose the ideal level of insulation for their specific climate and energy efficiency goals.

Acoustic Performance Characteristics

In addition to their thermal insulation properties, fireproof insulation panels also offer impressive acoustic performance. The dense materials used in their construction, particularly rock wool and glass wool, are excellent at absorbing sound waves. This makes these panels ideal for creating quieter environments in various settings, from residential buildings to industrial facilities.

The acoustic benefits of fireproof insulation panels are particularly valuable in urban areas or near transportation hubs, where external noise pollution can be a significant concern. By effectively reducing sound transmission, these panels contribute to improved living and working conditions, enhancing overall comfort and productivity.

Applications and Versatility of Fireproof Insulation Panels

Residential and Commercial Construction

Fireproof insulation panels have found widespread application in both residential and commercial construction projects. In homes, these panels are commonly used for exterior walls, roofs, and interior partitions, providing a comprehensive solution for thermal regulation, fire safety, and noise reduction. The panels' customizable nature allows homeowners to choose from a variety of colors and finishes, ensuring that the insulation solution also complements the aesthetic vision of their home.

In commercial settings, fireproof insulation panels are particularly valued for their ability to meet strict building codes and safety regulations. Office buildings, shopping centers, and educational institutions benefit from the panels' energy-efficient properties, which can significantly reduce operational costs. Moreover, the superior fire resistance of these panels provides an additional layer of safety for occupants, which is crucial in high-traffic commercial environments.

Industrial and Specialized Applications

The versatility of fireproof insulation panels extends well beyond traditional construction. In industrial settings, these panels are invaluable for creating safe and energy-efficient environments in factories, warehouses, and processing plants. The panels' resistance to extreme temperatures and corrosive elements makes them ideal for use in challenging industrial environments where safety and durability are paramount.

Fireproof insulation panels also find application in specialized sectors such as transportation. They are used in the construction of vehicles, ships, and aircraft, where weight considerations are critical. The panels' lightweight yet highly insulative properties make them an excellent choice for improving energy efficiency and safety in these mobile applications.

Renovation and Retrofit Projects

The adaptability of fireproof insulation panels makes them an excellent choice for renovation and retrofit projects. Whether updating a historic building or modernizing an older structure, these panels can be integrated seamlessly to improve energy efficiency and fire safety without compromising the original architectural integrity.

For retrofit projects, the panels' ease of installation is a significant advantage. They can be quickly and efficiently attached to existing structures, minimizing downtime and disruption. This makes fireproof insulation panels an attractive option for businesses looking to upgrade their facilities without extensive closures or lengthy construction periods.

Installation and Maintenance of Fireproof Insulation Panels

Installation Process and Best Practices

The installation of fireproof insulation panels is a critical process that requires attention to detail to ensure optimal performance. The process typically begins with thorough preparation of the surface, ensuring it is clean, dry, and structurally sound. Panels are then cut to size if necessary, using appropriate tools to maintain the integrity of the materials.

Attachment of the panels to the structure is done using specialized fasteners designed for the specific panel type and substrate. It's crucial to follow the manufacturer's guidelines regarding fastener spacing and installation techniques to ensure the panels are securely attached and maintain their fire-resistant properties.

Sealing is another critical step in the installation process. High-quality sealants are applied to edges and joints to enhance insulation performance and prevent moisture infiltration. This step is essential for maintaining the panels' thermal and acoustic properties and preventing potential degradation over time.

Maintenance and Long-Term Performance

One of the key advantages of fireproof insulation panels is their low maintenance requirements. The panels are designed to be durable and resistant to environmental factors such as UV radiation, moisture, and temperature fluctuations. However, regular inspections are recommended to ensure ongoing performance and identify any potential issues early.

Maintenance typically involves simple cleaning to remove dirt and debris, which can be done with mild detergents and water. The panels' surfaces are designed to resist fading and degradation, maintaining their appearance and integrity over time. In the rare event of damage, individual panels can often be replaced without the need for extensive renovations, further contributing to their cost-effectiveness over the long term.

Customization and Aesthetic Considerations

Flame resistant cover boards offer a wide extend of customization choices to meet particular extend necessities and stylish inclinations. Custom sizes are accessible, with boards made up to 3000mm x 1200mm, permitting for adaptability in plan and application. The assortment of surface medicines, counting coatings and paint wraps up, empowers planners and creators to make outwardly engaging veneers that complement the by and large building design.

Color coordinating administrations are frequently accessible, permitting boards to be created in for all intents and purposes any wanted tone. This level of customization guarantees that flame resistant separator boards can be consistently coordinates into any structural fashion, from present day moderate plans to more conventional aesthetics. The capacity to combine usefulness with visual offer makes these boards a favorite among modelers and builders looking to make secure, productive, and alluring structures.

Conclusion

Fireproof insulation panels represent a significant advancement in building materials, offering an unparalleled combination of thermal efficiency, acoustic performance, and fire safety. Their versatility, durability, and customization options make them an ideal choice for a wide range of construction and renovation projects. As the construction industry continues to prioritize energy efficiency and safety, these innovative panels are poised to play an increasingly important role in shaping the built environment of the future.

For more information on how fireproof insulation panels can enhance your next construction project, or to explore our range of exterior cladding and facade solutions, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.