The Science Behind PU Insulation Panel Technology

Composition and Manufacturing Process

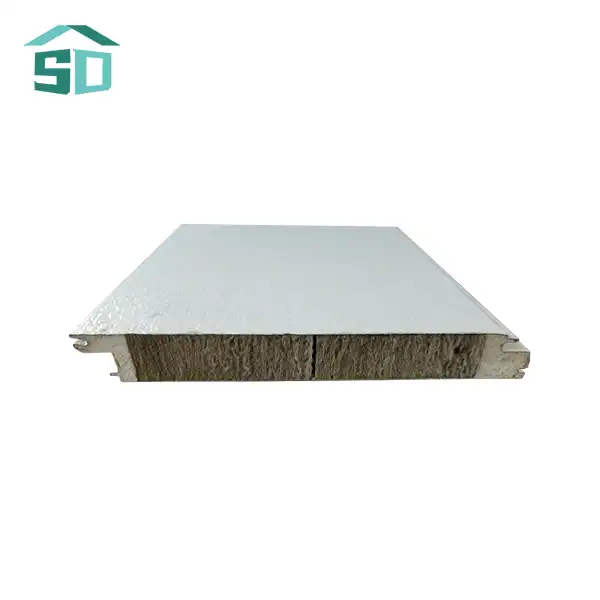

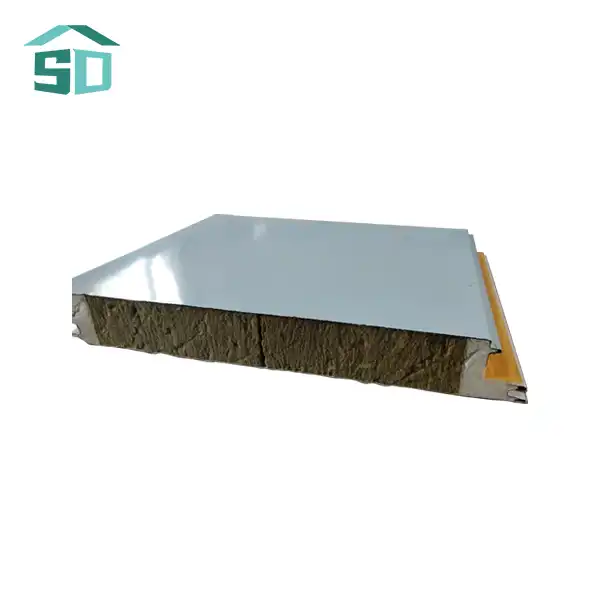

PU sequestration panels are the result of slice-edge polymer wisdom and advanced manufacturing ways. The core of these panels consists of polyurethane froth, a synthetic material known for its exceptional separating properties. This froth is created through a chemical response between polyol and isocyanate, forming an unrestricted-cell structure that traps air and provides superior thermal resistance.

The manufacturing process involves carefully controlling the expansion of this foam between two facings, typically made of metal or other durable materials. This sandwich-like structure not only enhances the panel's strength but also contributes to its fire-resistant properties. The thickness of the foam core can be adjusted to meet specific insulation requirements, with common ranges for interior applications being around 10mm and exterior applications ranging from 16mm to 20mm.

Technical Specifications and Performance Metrics

PU insulation panels boast impressive technical specifications that set them apart in the construction industry. With a thermal conductivity as low as 0.018W/m.k, these panels offer exceptional insulation performance. Their thermal resistance value of 2.09m2k/w ensures that heat transfer is minimized, contributing to significant energy savings in both heating and cooling applications.

The panels' fire protection rating of B1/B2 provides peace of mind for building occupants and meets stringent safety regulations. Additionally, with a waterproof rate of 0.0008 and wind resistance of 8.0 Kpa, these panels are well-equipped to handle diverse environmental conditions. The compressive strength of 52.7kpa further underscores their durability and load-bearing capacity, making them suitable for a wide range of architectural applications.

Advantages of PU Insulation Panels in Modern Construction

Energy Efficiency and Cost Savings

One of the primary benefits of incorporating PU insulation panels into building designs is the significant boost in energy efficiency. The superior insulation properties of these panels create an effective thermal barrier, reducing heat loss in winter and heat gain in summer. This translates to lower energy consumption for heating, ventilation, and air conditioning (HVAC) systems, resulting in substantial cost savings over the life of the building.

Moreover, the high R-value of PU insulation panels allows for thinner wall constructions compared to traditional insulation materials. This can lead to increased usable floor space in buildings, potentially enhancing property value and rental income. The long-term durability of these panels also means fewer replacements and maintenance costs, further contributing to their cost-effectiveness.

Versatility in Design and Application

PU insulation panels offer remarkable versatility in both design and application. Available in a range of thicknesses and widths (exterior panels typically 383mm wide and interior panels 450mm wide), these panels can be easily customized to suit specific project requirements. The surface materials, with thicknesses varying from 0.23mm to 0.27mm, can be finished in a variety of colors and textures, allowing architects and designers to achieve their desired aesthetic without compromising on insulation performance.

These panels are equally effective in new construction and renovation projects, suitable for both interior and exterior applications. From residential complexes and office buildings to industrial facilities and cold storage units, PU insulation panels adapt to diverse architectural needs. Their lightweight nature simplifies installation, reducing labor costs and construction timelines.

Installation and Maintenance: Ensuring Optimal Performance

Best Practices for PU Panel Installation

Proper installation is crucial to maximize the benefits of PU insulation panels. The process begins with thorough surface preparation, ensuring that the substrate is clean, dry, and free from any debris or irregularities. Accurate measurements and precise cutting of panels are essential to achieve a snug fit and minimize thermal bridging.

When fixing the panels, it's important to use appropriate fasteners and adhesives as recommended by the manufacturer. For exterior applications, special attention should be given to creating a weather-tight seal, particularly at joints and penetrations. Many manufacturers offer specialized joint systems and sealants designed specifically for use with their PU panels, ensuring optimal performance and longevity.

Long-term Maintenance and Performance Monitoring

One of the advantages of PU insulation panels is their low maintenance requirements. However, regular inspections are recommended to ensure continued performance. These inspections should focus on checking for any physical damage, ensuring that seals and joints remain intact, and verifying that the panels are securely fastened.

In the rare event of damage, individual panels can often be replaced without disturbing the entire installation, minimizing repair costs and downtime. It's also advisable to periodically assess the building's energy performance to confirm that the insulation system continues to deliver the expected thermal efficiency. This can be done through thermal imaging or energy audits, which can identify any areas of heat loss or potential improvements.

Conclusion

PU insulation panels represent a significant advancement in building technology, offering a combination of superior thermal performance, fire safety, and design flexibility. As the construction industry continues to prioritize energy efficiency and sustainability, these panels are poised to play an increasingly important role in creating comfortable, safe, and environmentally responsible buildings. For those interested in exploring PU insulation panel solutions for their next project, we invite you to contact us at info@sdqsc.com for expert guidance and product information.