The Science Behind Prefabricated Thermal Panels

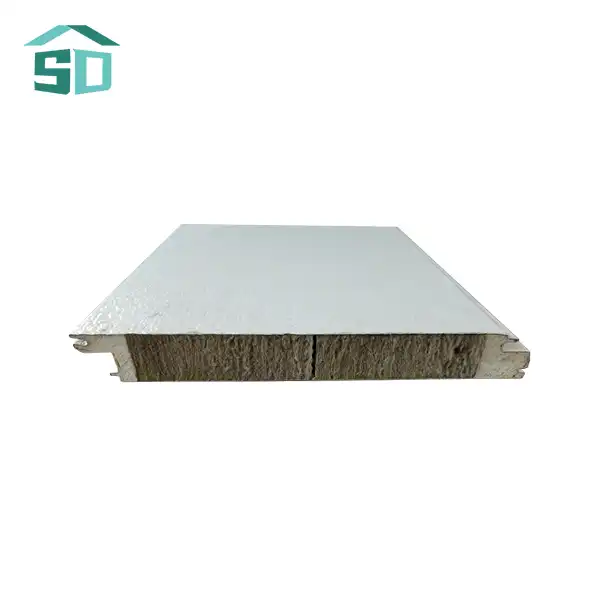

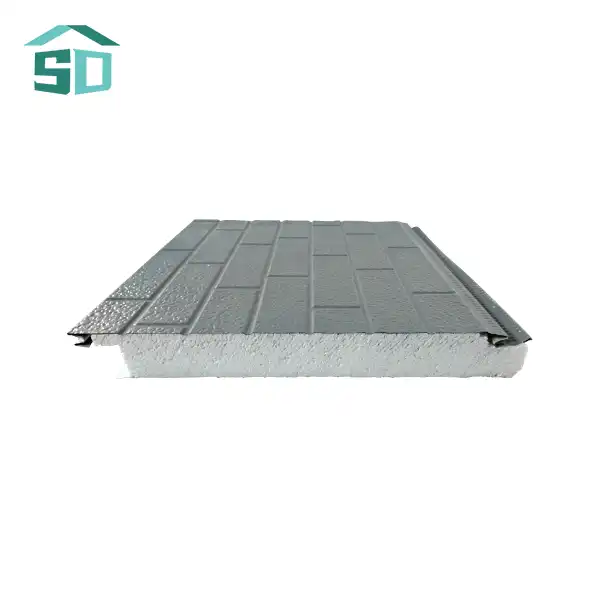

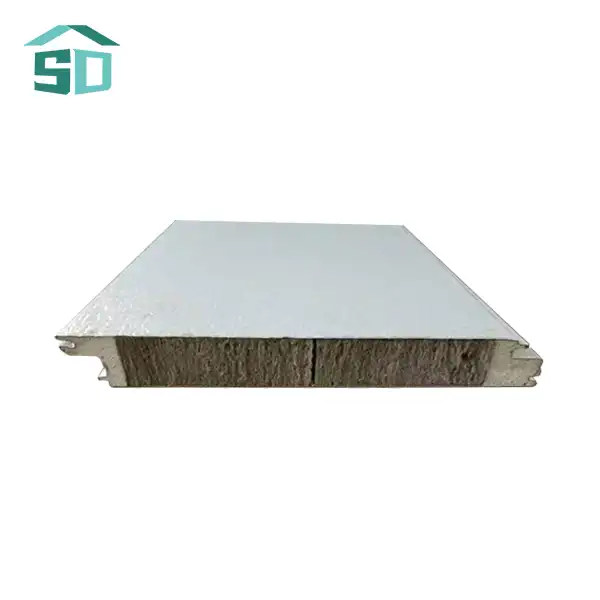

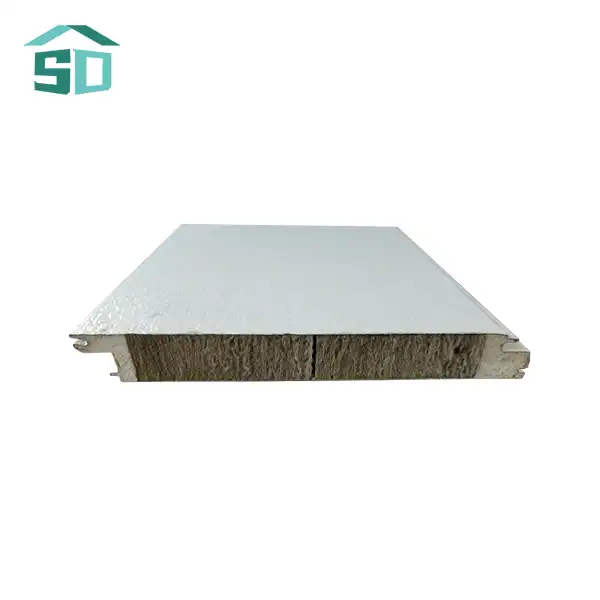

Prefabricated thermal panels are engineered to provide optimal insulation through a combination of cutting-edge materials and thoughtful design. These panels typically consist of a core insulation material, such as polyurethane foam or mineral wool, sandwiched between two durable outer layers made from metal or composite materials. This layered construction creates a robust and continuous barrier against heat transfer, significantly reducing energy loss while also enhancing structural strength, moisture resistance, and overall building envelope performance.

Core Insulation Materials

The heart of prefabricated thermal panels lies in their core insulation materials. Common options include:

- Polyurethane foam: Known for its excellent thermal resistance and moisture barrier properties

- Polystyrene: Lightweight and cost-effective, offering good insulation value

- Rock wool: Fire-resistant and soundproof, ideal for applications requiring enhanced safety

- Glass wool: Eco-friendly option with good thermal and acoustic insulation properties

Each of these materials brings unique characteristics to the table, allowing manufacturers to tailor panels for specific project requirements.

Thermal Bridging Prevention

One of the key advantages of prefabricated thermal panels is their ability to minimize thermal bridging. This phenomenon occurs when heat finds a path of least resistance through building materials, reducing overall insulation effectiveness and increasing energy consumption. By incorporating continuous insulation throughout the panel, manufacturers can significantly reduce thermal bridging, thereby enhancing the overall thermal performance, improving occupant comfort, and contributing to long-term energy savings and environmental sustainability of the building envelope.

Benefits of Prefabricated Thermal Panels in Construction

The adoption of prefabricated thermal panels offers numerous advantages for construction projects, ranging from improved energy efficiency to streamlined installation processes.

Energy Efficiency and Cost Savings

Prefabricated thermal panels excel in providing superior insulation, leading to substantial energy savings over the long term. By maintaining consistent indoor temperatures regardless of external weather conditions, these panels significantly reduce the load on HVAC systems. This results in lower energy consumption and decreased utility bills. The improved thermal efficiency not only enhances occupant comfort but also contributes to the building's overall sustainability, aligning with modern green building standards and environmental conservation goals.

Rapid Installation and Reduced Labor Costs

The prefabricated nature of these panels allows for quick and efficient installation. Unlike traditional insulation methods that require multiple steps and materials, prefabricated thermal panels can be easily assembled on-site, reducing construction time and labor costs. This streamlined process is particularly beneficial for large-scale projects or those with tight deadlines.

Versatility in Design and Application

Prefabricated thermal panels offer remarkable versatility in terms of design and application. Available in various sizes, thicknesses, and finishes, these panels can be customized to meet specific architectural requirements. Whether it's a sleek modern facade or a traditional aesthetic, prefabricated thermal panels can be tailored to suit diverse design preferences while maintaining their core insulation properties.

Advancements in Prefabricated Thermal Panel Technology

The field of prefabricated thermal panels continues to evolve, with ongoing innovations enhancing their performance and expanding their applications.

Smart Insulation Systems

Recent advancements have led to the development of smart insulation systems integrated into prefabricated thermal panels. These systems incorporate built-in sensors and adaptive materials that respond dynamically to environmental changes such as temperature and humidity. By adjusting their insulation properties in real time, these smart panels can optimize thermal performance throughout the year, enhancing energy efficiency while providing consistent indoor comfort across different climates and seasonal conditions.

Sustainable Materials and Manufacturing

As sustainability becomes increasingly important in modern construction, manufacturers are prioritizing the development of prefabricated thermal panels using environmentally responsible materials and production methods. This includes integrating recycled components, bio-based insulation cores, and energy-efficient fabrication techniques. These sustainable practices not only reduce the panels' overall environmental impact but also contribute to achieving green building certifications, making them an attractive option for eco-conscious developers and architects seeking to reduce the carbon footprint of construction projects.

Enhanced Fire Safety and Acoustic Performance

Ongoing research and innovation have produced prefabricated thermal panels with significantly improved fire safety ratings and enhanced acoustic insulation capabilities. These advancements expand the usability of such panels to include high-rise buildings, healthcare facilities, educational institutions, and other noise-sensitive or safety-critical environments. By combining thermal, acoustic, and fire-resistant features in a single system, these panels offer a comprehensive solution that addresses multiple performance criteria in modern architectural and construction projects.

Conclusion

Prefabricated thermal panels represent a significant leap forward in building insulation technology. Their superior thermal performance, combined with ease of installation and versatility, makes them an attractive option for modern construction projects. As the industry continues to innovate, we can expect even more advanced and sustainable prefabricated thermal panel solutions to emerge, further transforming the way we approach energy-efficient building design. For more information on our prefabricated thermal panels and how they can benefit your next construction project, please contact us at info@sdqsc.com.

FAQs

What are the main advantages of using prefabricated thermal panels?

Prefabricated thermal panels offer superior insulation, quick installation, energy efficiency, and design versatility.

How do prefabricated thermal panels compare to traditional insulation methods?

They provide better overall insulation, faster installation, and often result in thinner wall assemblies compared to traditional methods.

Are prefabricated thermal panels suitable for both new construction and renovation projects?

Yes, these panels can be used effectively in both new builds and retrofitting existing structures.

What types of buildings can benefit from prefabricated thermal panels?

They are suitable for a wide range of structures, including residential, commercial, industrial, and institutional buildings.

References

1.International Journal of Building Pathology and Adaptation. "Thermal performance of prefabricated building envelope systems." (2020)

2.Energy and Buildings. "Advanced thermal insulation technologies in the built environment: A review." (2019)

3.Construction and Building Materials. "Prefabricated wall panels for energy-efficient buildings: A state-of-the-art review." (2021)