The Economic Advantages of Steel PU Sandwich Panels

Initial Investment vs. Long-Term Savings

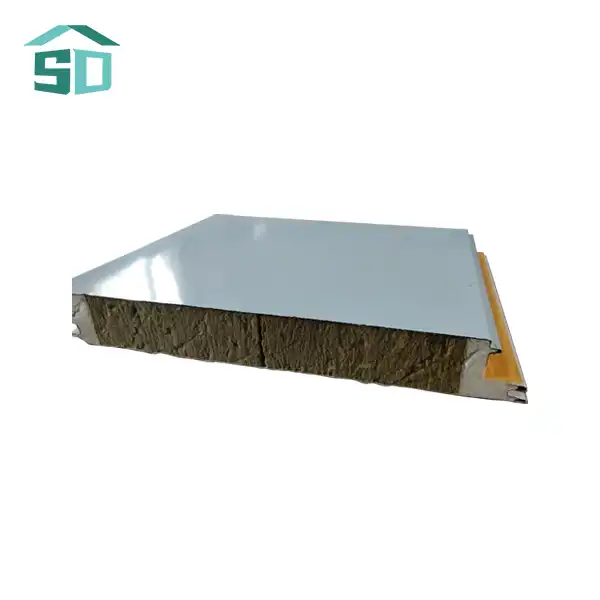

When evaluating the cost-effectiveness of steel PU sandwich panels, it's crucial to consider both the initial outlay and the potential for long-term savings. While the upfront cost of these panels may be higher than some traditional materials, their unique properties often lead to significant reductions in energy costs over time. The high-density polyurethane core provides exceptional thermal insulation, which can dramatically decrease heating and cooling expenses. This energy efficiency not only contributes to lower utility bills but also aligns with increasingly stringent environmental regulations, potentially avoiding future costs associated with building upgrades.

Reduced Labor and Installation Costs

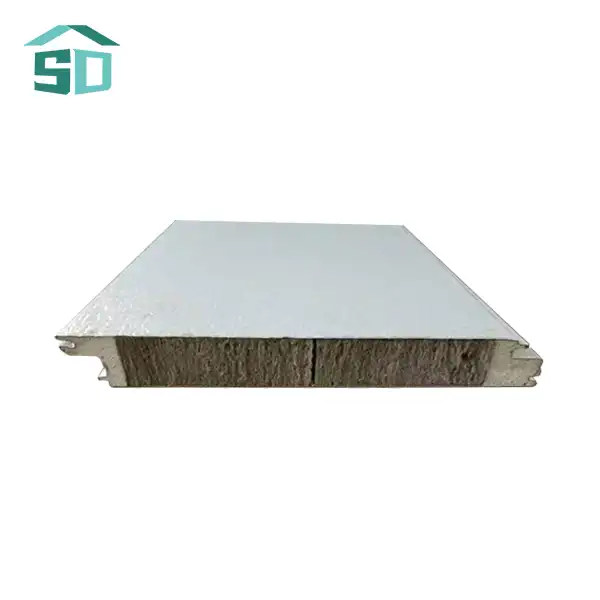

One of the most appealing aspects of steel PU sandwich panels is their ease of installation. The lightweight yet strong nature of these panels simplifies the construction process, reducing the need for heavy machinery and extensive labor. This streamlined installation process can lead to substantial savings in terms of both time and labor costs. Furthermore, the panels' design allows for quick assembly, potentially shortening project timelines and minimizing associated expenses such as equipment rental and on-site supervision.

Durability and Maintenance Savings

The durability of steel PU sandwich panels is a key factor in their long-term cost-effectiveness. These panels are engineered to withstand harsh weather conditions, resist corrosion, and maintain their structural integrity over time. This resilience translates to reduced maintenance requirements and a longer lifespan compared to many traditional building materials. The potential savings on repairs, replacements, and ongoing maintenance can be substantial, especially for large-scale or commercial projects where upkeep costs can be significant.

Comparing Steel PU Sandwich Panels to Traditional Materials

Insulation Performance and Energy Efficiency

When comparing steel PU sandwich panels to traditional insulation methods, the difference in thermal performance is notable. The polyurethane core offers superior insulation properties, often outperforming conventional materials like fiberglass or mineral wool. This enhanced insulation can lead to significant energy savings, particularly in regions with extreme temperatures. While traditional materials may require thicker walls to achieve similar insulation values, steel PU sandwich panels can provide excellent thermal resistance with a slimmer profile, potentially increasing usable interior space.

Structural Integrity and Load-Bearing Capacity

Steel PU sandwich panels offer a unique combination of lightweight construction and high structural strength. This balance allows for efficient load distribution and can potentially reduce the need for additional support structures in some building designs. Traditional materials like concrete or brick may provide comparable strength but often at the cost of increased weight and complexity in construction. The lightweight nature of steel PU panels can also lead to savings in foundation costs, as the overall load on the building's base is reduced.

Fire Safety and Regulatory Compliance

Fire safety is a critical consideration in construction, and steel PU sandwich panels are designed to meet stringent fire resistance standards. With a Class A fire rating, these panels offer peace of mind and compliance with building regulations. Traditional materials may require additional fire-resistant treatments or layering to achieve similar levels of protection, potentially increasing overall costs. The inherent fire resistance of steel PU panels can simplify the design process and reduce the need for supplementary fire safety measures.

Cost Analysis: Steel PU Sandwich Panels in Various Applications

Residential Construction

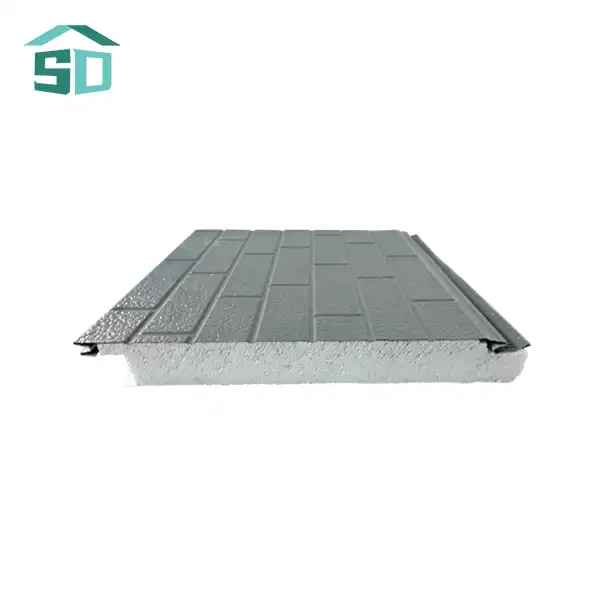

In residential construction, the use of steel PU sandwich panels can offer homeowners a balance between aesthetic appeal and practical benefits. While the initial cost may be higher than traditional wood framing or brick construction, the long-term energy savings and reduced maintenance can make these panels an attractive option. Additionally, the customizable nature of steel PU panels allows for a wide range of architectural designs, potentially increasing property value without the need for costly custom fabrication.

Commercial and Industrial Buildings

For commercial and mechanical applications, steel PU sandwich boards show a compelling cost-benefit suggestion. The fast establishment preparation can altogether diminish development timelines, permitting businesses to gotten to be operational sooner. The panels' fabulous separator properties are especially important in mechanical settings where temperature control is vital, such as distribution centers or nourishment handling offices. The potential for vitality investment funds in large-scale buildings can be significant, frequently offsetting the higher introductory venture inside a generally brief period.

Renovation and Retrofit Projects

When it comes to redesign and retrofit ventures, steel PU sandwich boards offer interesting points of interest. Their lightweight nature makes them perfect for including cover and modernizing existing structures without the require for broad auxiliary adjustments. This can be especially cost-effective in more seasoned buildings where conventional retrofitting strategies might be restrictively costly or troublesome. The panels' flexibility permits for both inside and outside applications, giving adaptability in remodel techniques and possibly amplifying the utilitarian life of maturing buildings.

Conclusion

While the initial cost of steel PU sandwich panels may be higher than some traditional materials, their long-term benefits often result in significant cost savings. From enhanced energy efficiency and reduced maintenance to streamlined installation and versatile applications, these panels offer a compelling value proposition for a wide range of construction projects. As the building industry continues to evolve towards more sustainable and efficient solutions, steel PU sandwich panels stand out as a cost-effective choice that balances performance, durability, and economic considerations.

For more information on how steel PU sandwich panels can benefit your specific project and for detailed cost comparisons, please contact us at info@sdqsc.com. Our team of experts is ready to help you make an informed decision that aligns with your construction goals and budget requirements.