The Science Behind PUF Sandwich Panels' Acoustic Excellence

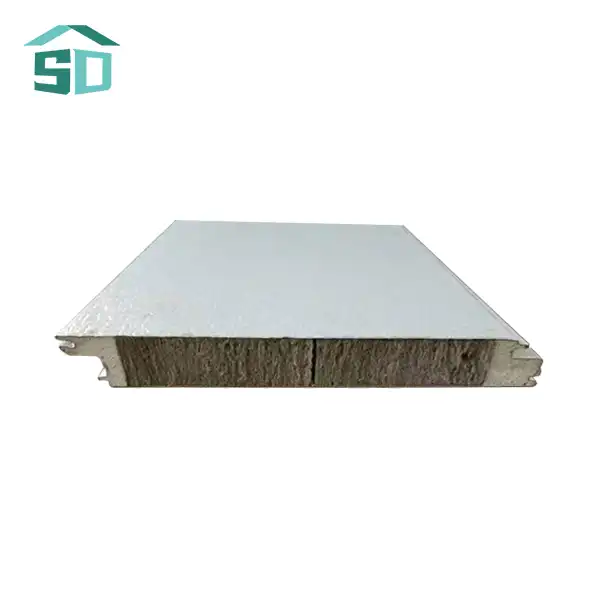

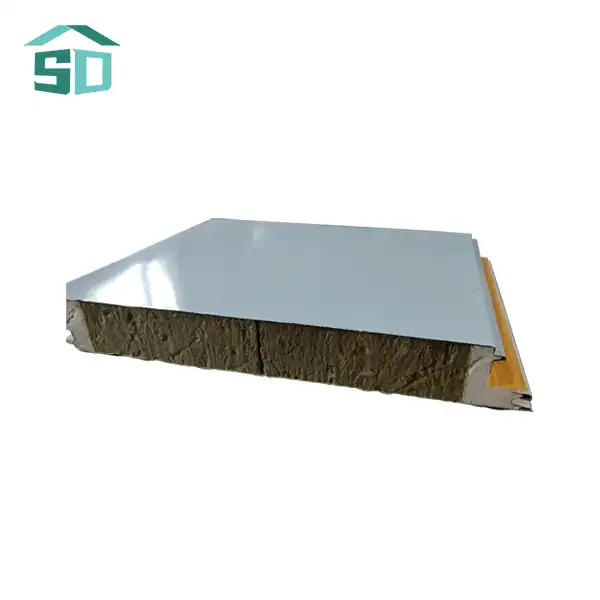

PUF sandwich panels owe their impressive acoustic performance to their unique composition and structure. The polyurethane foam core acts as an effective sound barrier, absorbing and dampening sound waves across a wide frequency range. This foam core, typically ranging from 50mm to 100mm in thickness, effectively reduces airborne noise transmission between spaces.

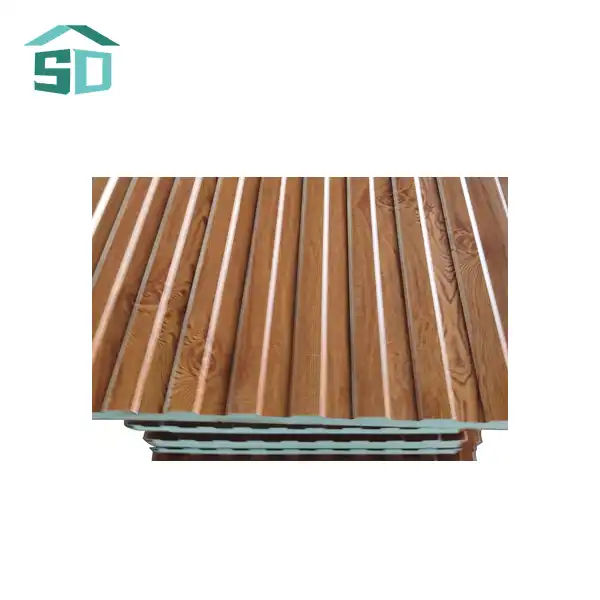

The metal facings of PUF sandwich panels, usually made of steel, aluminum, or stainless steel, further enhance their acoustic properties. These rigid outer layers reflect high-frequency sounds, while the foam core absorbs lower frequencies, resulting in a comprehensive noise reduction solution. This combination of reflection and absorption creates a balanced acoustic environment, ideal for various applications in prefab structures.

Moreover, the density and closed-cell structure of the polyurethane foam contribute significantly to its sound-dampening capabilities. The microscopic air pockets within the foam act as tiny shock absorbers, dissipating sound energy and preventing its transmission through the panel. This property is particularly beneficial in industrial settings or urban environments where external noise pollution can be a significant concern.

Acoustic Testing and Performance Metrics

To quantify the acoustic performance of PUF sandwich panels, manufacturers conduct rigorous testing using standardized methods. The Sound Transmission Class (STC) rating is a common metric used to measure the panels' ability to block airborne sound transmission. PUF sandwich panels typically achieve high STC ratings, often surpassing traditional building materials in noise reduction efficiency.

Another important metric is the Noise Reduction Coefficient (NRC), which measures the panel's ability to absorb sound rather than reflect it. PUF sandwich panels with specialized perforated facings can achieve impressive NRC values, making them ideal for applications where echo reduction and sound clarity are paramount.

Applications of PUF Sandwich Panels in Acoustic-Sensitive Environments

The exceptional acoustic properties of PUF sandwich panels make them an excellent choice for a wide range of prefab structures where sound control is crucial. These applications include:

Educational Facilities

In prefabricated classrooms and lecture halls, PUF sandwich panels create an optimal learning environment by reducing external noise interference and improving speech intelligibility. The panels' ability to absorb sound helps control reverberation, ensuring clear communication between teachers and students.

Healthcare Facilities

Prefab medical centers and hospitals benefit greatly from the acoustic performance of PUF sandwich panels. These panels help create quiet recovery rooms, reduce noise transmission between patient areas, and maintain privacy in consultation spaces. The panels' easy-to-clean surfaces also contribute to maintaining a hygienic environment.

Commercial and Office Spaces

In open-plan offices and shared workspaces, PUF sandwich panels can be used to create quiet zones and meeting rooms. Their sound-absorbing properties help reduce ambient noise levels, improving concentration and productivity. The panels' customizable finishes allow for seamless integration with modern office aesthetics.

Industrial Facilities

Prefabricated industrial buildings, such as factories and warehouses, often struggle with high noise levels from machinery and equipment. PUF sandwich panels can significantly reduce noise transmission both within the facility and to the surrounding environment, helping companies comply with noise regulations and improve worker comfort.

Installation and Maintenance for Optimal Acoustic Performance

To maximize the acoustic benefits of PUF sandwich panels in prefab structures, proper installation and maintenance are essential. Here are some key considerations:

Proper Sealing and Jointing

Ensuring airtight seals between panels is crucial for maintaining acoustic integrity. Use high-quality sealants and gaskets specifically designed for PUF sandwich panels to prevent sound leakage through joints and connections. Pay special attention to intersections with other building elements, such as windows, doors, and utility penetrations.

Strategic Panel Placement

Consider the layout of the prefab structure and strategically place PUF sandwich panels to create acoustic zones. Use thicker panels or double-layer configurations in areas requiring higher sound insulation, such as between noisy and quiet spaces.

Regular Inspection and Maintenance

Periodically inspect the panels for any damage, gaps, or deterioration that could compromise their acoustic performance. Address any issues promptly to maintain the panels' effectiveness. The durable nature of PUF sandwich panels typically requires minimal maintenance, but regular cleaning can help preserve their appearance and functionality.

Acoustic Accessories

Enhance the acoustic performance of PUF sandwich panels by incorporating complementary accessories. Acoustic baffles, sound-absorbing ceiling tiles, and specialized flooring can work in conjunction with the panels to create a comprehensive sound control solution in prefab structures.

By leveraging the acoustic properties of PUF sandwich panels and implementing proper installation and maintenance practices, prefab structures can achieve exceptional sound control. This not only enhances occupant comfort but also contributes to the overall efficiency and functionality of the building.

Conclusion

PUF sandwich panels have emerged as a game-changer in the prefabricated construction industry, offering unparalleled acoustic performance alongside their well-known thermal insulation properties. Their unique composition of a polyurethane foam core sandwiched between metal facings provides excellent sound absorption and noise reduction capabilities, making them ideal for a wide range of applications in acoustic-sensitive environments.

From educational facilities and healthcare centers to commercial spaces and industrial buildings, PUF sandwich panels create quieter, more comfortable environments while maintaining structural integrity and energy efficiency. Their versatility, ease of installation, and low maintenance requirements make them a cost-effective solution for modern prefab structures.

For more information on how PUF sandwich panels can enhance the acoustic performance of your prefab project, contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of experts is ready to help you find the perfect solution for your specific needs.

FAQ

How do PUF sandwich panels compare to traditional building materials in terms of acoustic performance?

PUF sandwich panels often outperform traditional materials due to their unique composition, offering superior sound absorption and transmission loss across a wide frequency range.

Can PUF sandwich panels be customized for specific acoustic requirements?

Yes, panel thickness, density, and facing materials can be adjusted to meet specific acoustic needs in different environments.

Are PUF sandwich panels suitable for outdoor acoustic applications?

Absolutely. Their weather-resistant properties make them ideal for outdoor noise barriers and enclosures.

References

1.Acoustic Society of America. (2021). Sound Transmission and Insulation in Buildings.

2.International Journal of Acoustics and Vibration. (2020). Performance of Sandwich Panels in Noise Control Applications.

3.Building and Environment. (2019). Acoustic Properties of Prefabricated Construction Materials.

4.Journal of Sound and Vibration. (2018). Polyurethane Foam: Advances in Acoustic Insulation Technology.