Introducing Metal Panel Types and Their Benefits

Metal panels have become increasingly popular for outdoor sheds due to their durability, versatility, and aesthetic appeal. When choosing the best metal panels for your shed, it's crucial to understand the different types available and their unique benefits.

Steel Panels: Strength and Affordability

Steel panels are a top choice for many shed owners. They offer exceptional strength and durability, making them resistant to impacts, high winds, and heavy snow loads. Steel is also relatively affordable, providing excellent value for money. These panels come in various gauges, with thicker gauges offering increased strength but at a higher cost. Steel panels can be galvanized or coated with paint or other protective finishes to enhance their corrosion resistance.

Aluminum Panels: Lightweight and Corrosion-Resistant

Aluminum panels are another popular option, particularly in coastal areas or regions with high humidity. They're naturally resistant to corrosion, making them an excellent choice for harsh environments. Aluminum is also significantly lighter than steel, which can make installation easier and reduce the load on your shed's structure. While typically more expensive than steel, aluminum panels require less maintenance over time due to their inherent corrosion resistance.

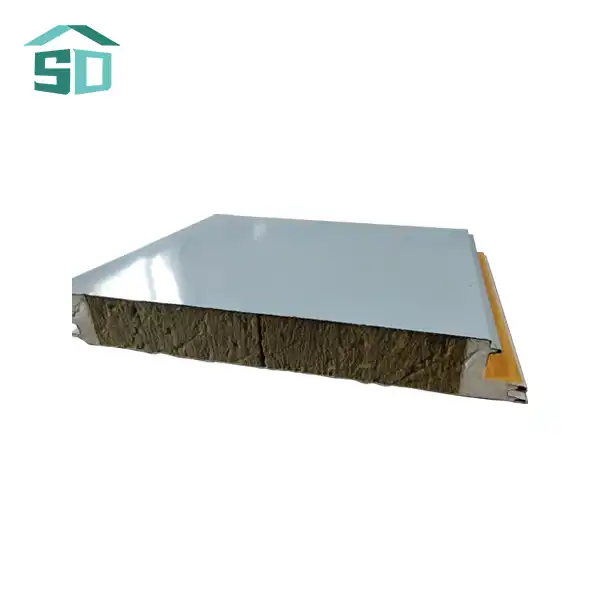

Insulated Metal Panels: Energy Efficiency and Comfort

For those looking to use their shed as a workspace or storage for temperature-sensitive items, insulated metal siding panels for shed are worth considering. These panels consist of a foam core sandwiched between two metal facings, providing excellent thermal insulation. They can help maintain a more stable interior temperature, potentially reducing energy costs if you plan to heat or cool your shed. Insulated panels also offer sound dampening properties, which can be beneficial if you're using power tools or machinery in your shed.

Factors to Consider When Selecting Metal Panels

Choosing the right metal panels for your outdoor shed involves more than just picking a material. Several factors come into play to ensure you select panels that will perform well and meet your specific needs.

Climate and Weather Considerations

Your local climate plays a significant role in determining the best metal panels for your shed. In areas with high rainfall, consider panels with a profile that efficiently sheds water, such as corrugated or ribbed designs. For regions prone to high winds, look for panels with interlocking systems or those rated for high wind resistance. In coastal areas or locations with high humidity, corrosion-resistant materials like aluminum or specially coated steel panels are crucial.

Gauge and Thickness

The gauge of metal panels refers to their thickness, with lower numbers indicating thicker metal. Thicker panels (lower gauge numbers) offer more strength and durability but come at a higher cost. For most residential sheds, 29-gauge panels provide a good balance of strength and affordability. However, if you live in an area with severe weather conditions or plan to store heavy equipment in your shed, you might want to consider 26-gauge or even 24-gauge panels for added strength.

Panel Profile and Aesthetic Appeal

The profile of metal panels not only affects their appearance but also their functionality. Common profiles include:

- Corrugated: These panels have a wavy pattern that efficiently sheds water and provides structural strength.

- Ribbed: Similar to corrugated but with more defined, often rectangular ridges.

- Standing seam: These panels have raised seams that interlock, providing excellent water resistance and a sleek, modern look.

- Flat: While less common for sheds due to reduced water-shedding ability, flat panels can offer a clean, contemporary aesthetic.

Choose a profile that complements your property's overall look while providing the necessary functionality for your climate.

Color and Finish Options

Metal siding panels for shed come in a wide array of colors and finishes, allowing you to customize the look of your shed. Many manufacturers offer color-matched fasteners to create a seamless appearance. When selecting a color, consider:

- Your home's exterior color scheme

- Local homeowner association guidelines

- Heat absorption (lighter colors reflect more heat, potentially keeping your shed cooler)

- Long-term color retention (some finishes are more resistant to fading)

Look for panels with high-quality paint systems or finishes that offer UV protection to maintain their appearance over time.

Installation and Maintenance Considerations

Proper installation and ongoing maintenance are crucial for ensuring the longevity and performance of your metal panels. Understanding these aspects can help you make an informed decision and get the most out of your investment.

Installation Methods and Complexity

The installation process for metal panels can vary depending on the type and profile you choose. Some considerations include:

- Direct fastening vs. concealed fastener systems

- Required underlayment or insulation

- Need for specialized tools or equipment

- Skill level required for proper installation

If you're planning a DIY installation, look for panels with user-friendly designs, such as those with easy-to-align edges or pre-drilled holes. For more complex systems or if you're not confident in your DIY skills, factor in the cost of professional installation when comparing options.

Long-term Maintenance Requirements

One of the advantages of metal panels is their relatively low maintenance needs compared to other materials. However, some upkeep is still necessary to ensure optimal performance:

- Regular cleaning to remove dirt, debris, and potential corrosive substances

- Inspection for damage, loose fasteners, or signs of wear

- Reapplication of protective coatings or paint as needed (frequency depends on the specific product and environmental conditions)

Consider the long-term maintenance requirements when choosing your panels. Some high-end finishes or materials may have a higher upfront cost but can save you time and money on maintenance in the long run.

Warranty and Durability

The warranty offered with metal siding panels for shed can be a good indicator of their expected durability and the manufacturer's confidence in their product. Look for:

- Length of warranty coverage

- What's covered (e.g., material defects, finish integrity, performance)

- Any specific maintenance requirements to keep the warranty valid

Remember that proper installation is often a prerequisite for warranty coverage, so if you're installing the panels yourself, make sure you follow the manufacturer's guidelines precisely.

Environmental Impact and Sustainability

If environmental considerations are important to you, factor in the sustainability aspects of different metal panel options:

- Recyclability of the material

- Energy efficiency (particularly relevant for insulated panels)

- Solar reflectance index (SRI) for reducing heat island effects

- Locally sourced options to reduce transportation emissions

Many metal panels are made from recycled materials and are fully recyclable at the end of their life, making them a relatively eco-friendly choice for your shed.

Conclusion

Choosing the best metal siding panels for shed requires careful consideration of various factors, including material type, climate suitability, aesthetic preferences, and long-term performance. By understanding the different options available and weighing them against your specific needs, you can select panels that will provide durability, functionality, and visual appeal for years to come. Remember to factor in installation complexity, maintenance requirements, and environmental impact in your decision-making process. With the right metal panels, your outdoor shed can become a sturdy, attractive, and long-lasting addition to your property.

For expert guidance on selecting the perfect metal panels for your outdoor shed, consider reaching out to Weifang Sandong Building Materials Co., Ltd. Our team specializes in exterior cladding and facade solutions, including high-quality metal panels suitable for a variety of applications. We're committed to providing innovative, efficient, and environmentally friendly solutions that meet your specific needs. Contact us at info@sdqsc.com to explore our range of metal panels and find the ideal solution for your outdoor shed project.

FAQ

What are the most durable metal panels for outdoor sheds?

Steel and aluminum panels are generally considered the most durable options, with steel offering superior strength and aluminum providing excellent corrosion resistance.

How do I maintain metal panels on my shed?

Regular cleaning, inspection for damage, and occasional reapplication of protective coatings (if applicable) are key maintenance tasks for metal panels.

Are insulated metal panels worth the extra cost for a shed?

If you plan to use your shed as a workspace or need to maintain specific interior temperatures, insulated panels can be a worthwhile investment for improved energy efficiency and comfort.

References

1.Metal Construction Association. (2021). Metal Roofing and Wall Panel Design Guide.

2.American Iron and Steel Institute. (2020). Steel Panel Selection Guide for Building Envelopes.

3.Aluminum Association. (2019). Aluminum Design Manual.

4.U.S. Department of Energy. (2022). Energy Efficiency in Metal Buildings.

5.National Roofing Contractors Association. (2021). The NRCA Roofing Manual: Metal Panel and SPF Roof Systems.