Environmental Impact of Corrugated Sandwich Panel Production

Raw Material Extraction and Processing

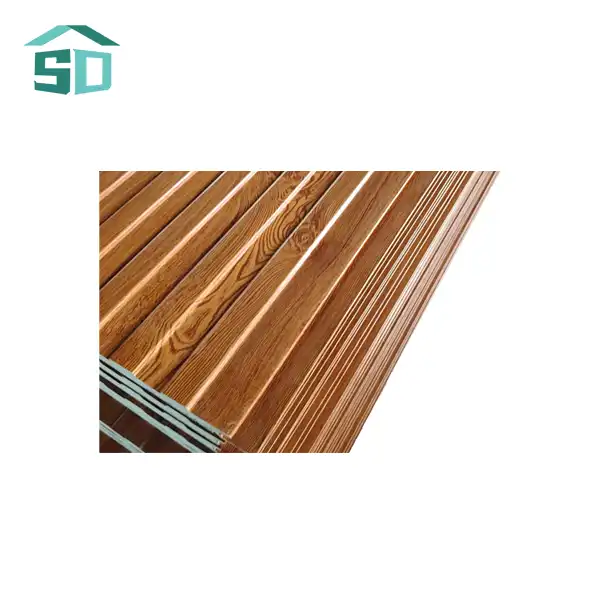

The production of corrugated sandwich panels begins with the extraction and processing of raw materials. The environmental impact of this stage varies depending on the specific materials used. For panels with metal facings, such as aluminum or steel, the mining and refining processes contribute significantly to the overall carbon footprint. However, many corrugated sandwich panel manufacturers are now using recycled metals in their production, which can substantially reduce the environmental impact.

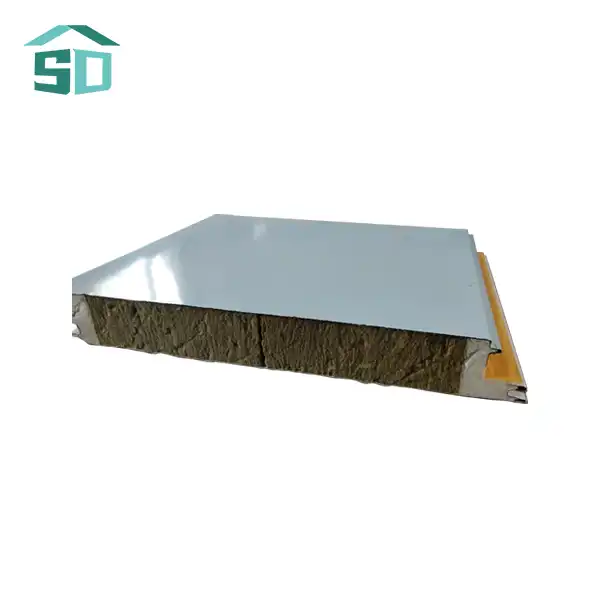

The core material, typically made of polyurethane, polystyrene, or rock wool, also plays a crucial role in the panel's carbon footprint. While these materials require energy-intensive production processes, their insulation properties contribute to significant energy savings during the building's operational phase, offsetting the initial carbon cost.

Manufacturing Process and Energy Consumption

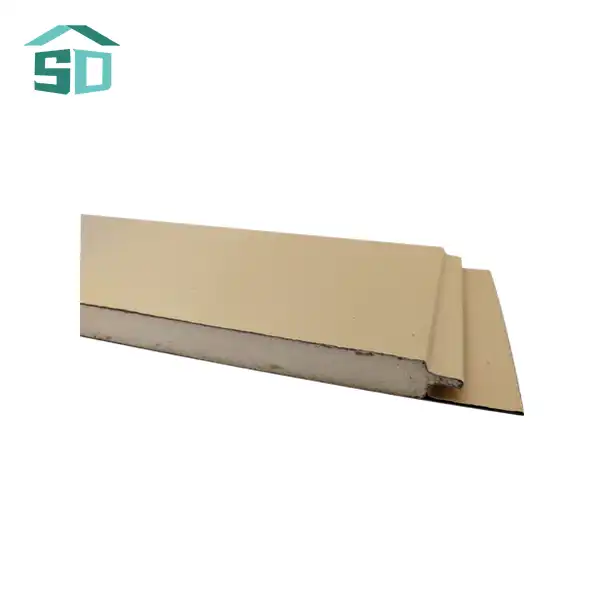

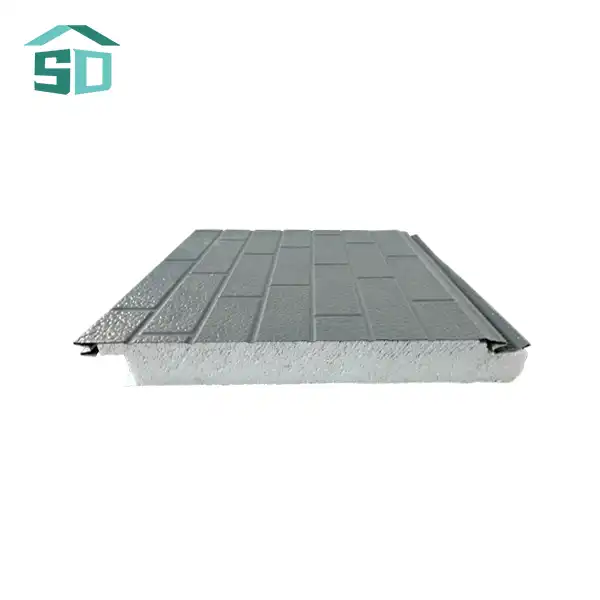

The manufacturing process of corrugated sandwich panels involves several stages, including forming the metal sheets, applying protective coatings, and bonding the core material. Modern production lines have become increasingly efficient, with many manufacturers implementing energy-saving measures and utilizing renewable energy sources. The continuous production process used for corrugated sandwich panels allows for optimal resource utilization and minimal waste generation.

Advancements in technology have led to the development of more eco-friendly bonding agents and coating materials, further reducing the environmental impact of the manufacturing process. Some corrugated sandwich panel suppliers have invested in state-of-the-art facilities that incorporate closed-loop systems, recycling water and materials to minimize resource consumption and waste generation.

Transportation and Distribution

The lightweight nature of corrugated sandwich panels offers significant advantages in terms of transportation and distribution. Compared to traditional building materials, these panels require less fuel for transportation, resulting in lower carbon emissions. Additionally, their modular design allows for efficient packing and shipping, further reducing the environmental impact associated with logistics.

Many corrugated sandwich panel manufacturers have implemented strategies to optimize their distribution networks, such as locating production facilities closer to major markets or utilizing more fuel-efficient transportation methods. These efforts contribute to a reduction in the overall carbon footprint of the product lifecycle.

Energy Efficiency and Longevity of Corrugated Sandwich Panels

Thermal Performance and Energy Savings

One of the most significant advantages of corrugated sandwich panels is their exceptional thermal performance. The insulating core material, combined with the reflective properties of the metal facings, creates a highly effective barrier against heat transfer. This results in substantial energy savings for heating and cooling throughout the building's lifespan.

The energy efficiency of corrugated sandwich panels contributes significantly to reducing the overall carbon footprint of buildings. By minimizing heat loss in winter and heat gain in summer, these panels help to lower the energy consumption required for maintaining comfortable indoor temperatures. This not only reduces operational costs but also decreases the building's reliance on fossil fuels for climate control.

Durability and Maintenance Requirements

Corrugated sandwich panels are renowned for their durability and low maintenance requirements. The metal facings provide excellent protection against weathering, corrosion, and UV radiation, ensuring a long service life. This longevity is a crucial factor in reducing the lifecycle carbon footprint, as it minimizes the need for replacement and repairs.

The robust construction of corrugated sandwich panels also contributes to their resistance to impact damage and structural deformation. This durability not only extends the lifespan of the panels but also helps maintain their thermal performance over time, ensuring consistent energy efficiency throughout their use phase.

Adaptability and Potential for Reuse

Another aspect that contributes to the sustainability of corrugated sandwich panels is their adaptability and potential for reuse. The modular nature of these panels allows for easy disassembly and reconfiguration, making them ideal for temporary structures or buildings that may require future modifications. This flexibility extends the useful life of the panels and reduces the need for new materials in future construction projects.

In some cases, corrugated sandwich panels can be repurposed for different applications at the end of their initial use phase. For example, panels from a decommissioned industrial building could be reused in agricultural structures or storage facilities, further extending their lifecycle and reducing overall resource consumption.

End-of-Life Options and Recyclability

Disassembly and Material Separation

When corrugated sandwich panels reach the end of their useful life, the first step in the recycling process is disassembly and material separation. The design of these panels typically allows for relatively easy separation of the metal facings from the insulating core. This separation is crucial for maximizing the recyclability of the individual components.

Advanced recycling facilities have developed specialized techniques for efficiently separating the different materials in corrugated sandwich panels. These processes may involve mechanical shredding, chemical treatments, or thermal separation methods, depending on the specific materials used in the panel construction.

Recycling Potential of Metal Facings

The metal facings of corrugated sandwich panels, whether made of aluminum or steel, have excellent recycling potential. These metals can be melted down and reprocessed into new products with minimal loss of quality. The recycling process for metals is well-established and highly efficient, consuming significantly less energy compared to primary metal production.

Many corrugated sandwich panel suppliers actively participate in metal recycling programs, either by accepting used panels for recycling or by incorporating recycled content into their new products. This closed-loop approach helps to reduce the demand for virgin materials and lower the overall environmental impact of panel production.

Challenges and Innovations in Core Material Recycling

The recycling of insulating core materials presents more challenges compared to metal facings. Traditional foam insulation materials like polyurethane and polystyrene are not as easily recyclable, often ending up in landfills. However, innovative technologies are emerging to address this issue.

Some manufacturers are developing new types of core materials that are more easily recyclable or biodegradable. Others are exploring chemical recycling processes that can break down foam insulation into its constituent components for reuse in new products. While these technologies are still evolving, they show promise for improving the overall recyclability of corrugated sandwich panels in the future.

Conclusion

Corrugated sandwich panels offer a compelling solution for sustainable construction, balancing performance with environmental responsibility. Working with a reliable corrugated sandwich panel supplier ensures access to high-quality panels that deliver superior thermal insulation, structural strength, and durability, while also meeting modern sustainability standards. Such partnerships enable builders and architects to achieve both functional efficiency and eco-friendly goals, making these panels an ideal choice for a wide range of contemporary building projects.

Their lifecycle carbon footprint is mitigated by energy-efficient production processes, exceptional thermal performance, and durability. The recyclability of these panels, particularly the metal components, contributes to a circular economy approach in the construction industry. As technology advances, we can expect further improvements in the recyclability of core materials, enhancing the overall sustainability profile of corrugated sandwich panels.

At Weifang Sandong Building Materials Co., Ltd., we are committed to providing high-quality, sustainable corrugated sandwich panels that meet the evolving needs of the construction industry. Our panels offer enhanced insulation, fire retardancy, and customizable designs, all while prioritizing environmental responsibility. For more information on our eco-friendly and resilient corrugated sandwich panel solutions, please contact us at info@sdqsc.com.

FAQ

What are the main environmental benefits of using corrugated sandwich panels?

Corrugated sandwich panels offer superior insulation, reducing energy consumption in buildings. They are durable, lowering replacement frequency, and often use recycled materials. Their lightweight nature also reduces transportation emissions.

How long do corrugated sandwich panels typically last?

With proper maintenance, corrugated sandwich panels can last 30-50 years, depending on the environment and application. Their durability contributes to a lower lifecycle carbon footprint.

Are all components of corrugated sandwich panels recyclable?

Metal facings are highly recyclable. The core materials present more challenges, but innovations in recyclable and biodegradable insulation are improving overall recyclability.

References

1.European Panel Federation. (2021). Environmental Product Declaration: Sandwich panels.

2.International Journal of Life Cycle Assessment. (2020). Life cycle assessment of insulated sandwich panels.

3.Building Research Establishment. (2019). Green Guide to Specification: Insulated sandwich panels.

4.Journal of Cleaner Production. (2018). Recycling of sandwich panels: A life cycle perspective.

5.Waste Management. (2022). Advances in recycling technologies for insulation materials in construction waste.