Streamlined Installation Process of Corrugated Sandwich Panels

Simplified Assembly and Reduced On-Site Fabrication

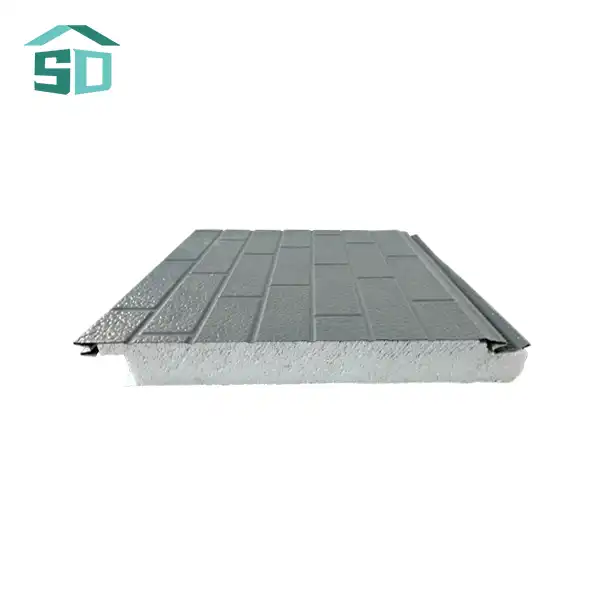

Corrugated sandwich panels offer a significant advantage in terms of simplified assembly and reduced on-site fabrication. These pre-engineered panels arrive at the construction site ready for installation, eliminating the need for time-consuming on-site cutting, shaping, and assembly of individual components. Choosing a trusted corrugated sandwich panel supplier ensures consistent quality and reliable delivery, making the installation process even more efficient. The modular nature of corrugated sandwich panels allows for a more efficient and streamlined installation process, reducing the overall labor hours required for completion.

The unique design of corrugated sandwich panels, with their interlocking edges and pre-drilled mounting points, facilitates rapid assembly. This design feature minimizes the need for specialized tools or skills, enabling construction teams to work more efficiently and reducing the likelihood of errors during installation. As a result, projects using corrugated sandwich panels can progress more quickly, leading to significant time and cost savings.

Reduced Need for Specialized Equipment

Another way corrugated sandwich panels improve site labor efficiency is by reducing the need for specialized equipment. Traditional construction methods often require various tools and machinery for cutting, shaping, and assembling different building components. In contrast, the installation of corrugated sandwich panels typically requires only basic tools and lifting equipment.

This reduction in specialized equipment needs not only streamlines the construction process but also minimizes the potential for equipment-related delays or breakdowns. Additionally, it reduces the need for skilled operators, further contributing to labor efficiency and cost savings. The simplicity of working with corrugated sandwich panels allows construction teams to focus on assembly rather than complex fabrication tasks, resulting in a more efficient use of labor resources.

Faster Weather Tightness Achievement

Corrugated sandwich panels excel in achieving weather tightness quickly, which is crucial for improving site labor efficiency. The large-format panels cover substantial areas in a single installation, reducing the number of joints and potential weak points in the building envelope. This characteristic allows construction teams to rapidly enclose the structure, protecting the interior from weather elements and enabling other trades to begin their work sooner.

The speed at which weather tightness is achieved with corrugated sandwich panels can significantly impact the overall project timeline. It reduces the risk of weather-related delays and allows for a more predictable construction schedule. This efficiency not only improves labor productivity but also contributes to better project management and cost control.

Enhanced Safety and Reduced Risk on Construction Sites

Lightweight Nature of Corrugated Sandwich Panels

The lightweight nature of corrugated sandwich panels is a key factor in enhancing safety and reducing risk on construction sites. Despite their robust construction and excellent insulation properties, these panels are significantly lighter than traditional building materials. This characteristic makes them easier to handle, transport, and install, reducing the physical strain on workers and minimizing the risk of injuries associated with heavy lifting.

The reduced weight of corrugated sandwich panels also allows for easier maneuverability during installation, particularly in challenging or confined spaces. This improved maneuverability not only enhances safety but also contributes to faster installation times and increased labor efficiency. Additionally, the lightweight nature of these panels can reduce the structural load on the building, potentially leading to savings in foundation and support structure costs.

Reduced Exposure to Hazardous Materials

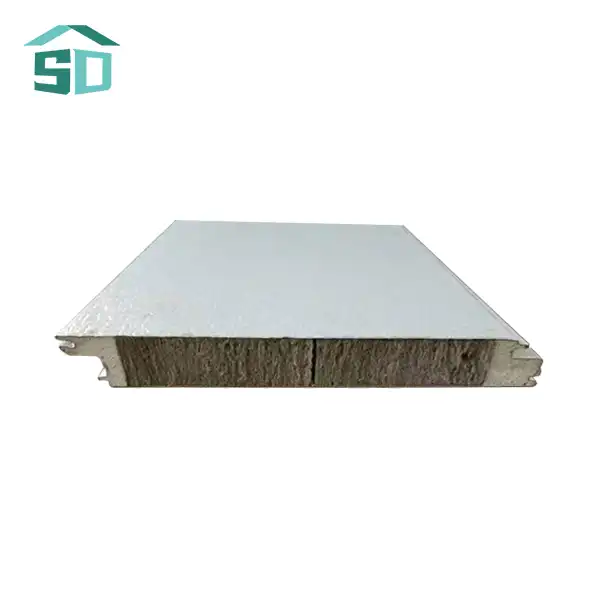

Corrugated sandwich panels contribute to improved site safety by reducing workers' exposure to hazardous materials. Unlike some traditional construction methods that involve on-site mixing of insulation materials or application of potentially harmful adhesives, corrugated sandwich panels come pre-assembled with their insulation core already in place. This pre-fabrication eliminates the need for workers to handle raw insulation materials or be exposed to chemical fumes during installation.

The reduced exposure to hazardous materials not only improves the immediate safety of the construction site but also contributes to long-term worker health. It minimizes the risk of respiratory issues, skin irritations, and other health concerns associated with handling certain building materials. This aspect of corrugated sandwich panels aligns with increasingly stringent workplace safety regulations and demonstrates a commitment to worker well-being.

Minimized On-Site Waste and Cleaner Work Environment

The use of corrugated sandwich panels significantly minimizes on-site waste, contributing to a cleaner and safer work environment. Traditional construction methods often generate substantial waste from cutting, trimming, and discarding excess materials. In contrast, corrugated sandwich panels are manufactured to precise specifications, reducing the need for on-site modifications and resulting in minimal waste.

A cleaner work environment, with less debris and waste material, reduces the risk of trips, slips, and falls - common accidents on construction sites. It also improves overall site organization and efficiency, allowing workers to move more freely and safely. The reduced waste generation also aligns with sustainable construction practices, potentially contributing to green building certifications and improved environmental performance of the project.

Long-Term Benefits and Cost Savings

Durability and Reduced Maintenance Requirements

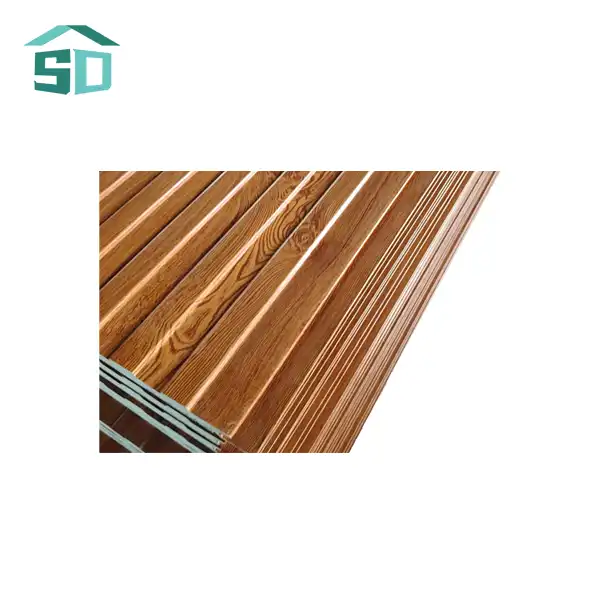

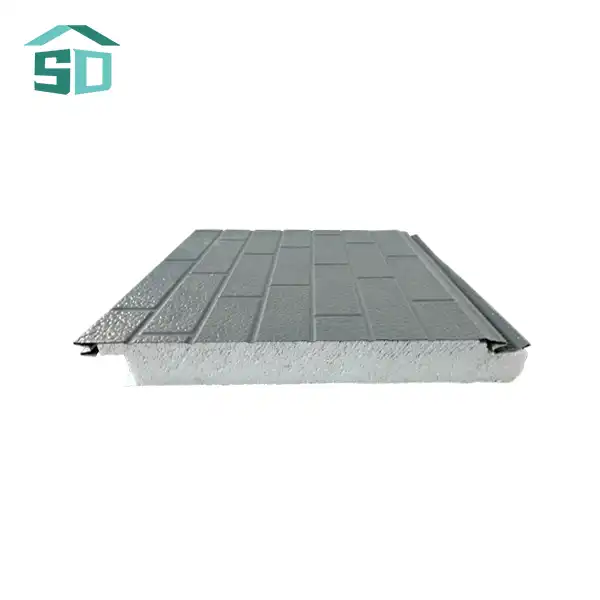

Corrugated sandwich panels offer exceptional durability, which translates to long-term benefits and cost savings. These panels are designed to withstand harsh environmental conditions, including extreme temperatures, high winds, and moisture exposure. The robust construction of corrugated sandwich panels, typically featuring high-quality steel or aluminum facings and a resilient insulation core, ensures longevity and resistance to wear and tear.

The durability of corrugated sandwich panels significantly reduces maintenance requirements over the life of the building. This reduction in maintenance needs not only saves on long-term labor costs but also minimizes disruptions to building operations. The panels' resistance to corrosion, fading, and structural degradation means fewer repairs and replacements, contributing to overall cost-effectiveness and improved building performance over time.

Energy Efficiency and Reduced Operational Costs

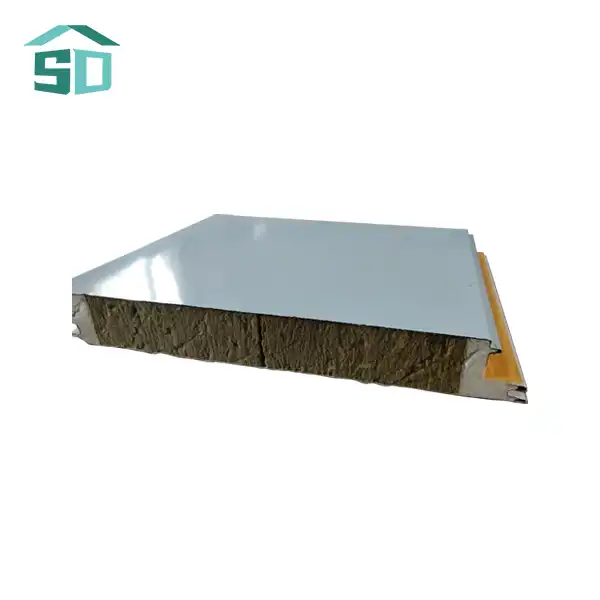

Corrugated sandwich panels excel in providing superior energy efficiency, leading to reduced operational costs for buildings. The insulation core of these panels, often made of materials like polyurethane, polystyrene, or rock wool, offers excellent thermal performance. This high-quality insulation helps maintain consistent indoor temperatures, reducing the load on heating and cooling systems.

The energy efficiency provided by corrugated sandwich panels can result in significant cost savings over the life of the building. Lower energy consumption not only reduces utility bills but also contributes to a smaller carbon footprint, aligning with sustainability goals. Additionally, the superior insulation properties of these panels can help buildings meet or exceed energy code requirements, potentially qualifying for energy-efficiency incentives or certifications.

Versatility and Adaptability for Future Modifications

The versatility and adaptability of corrugated sandwich panels offer long-term benefits in terms of future modifications and expansions. These panels can be easily disassembled and reassembled, allowing for changes to building layout or function without extensive demolition or reconstruction. This flexibility is particularly valuable for industrial, commercial, and institutional buildings that may need to adapt to changing needs over time.

The ability to modify or expand buildings constructed with corrugated sandwich panels can result in significant cost savings compared to traditional construction methods. It reduces the need for major renovations or new construction, extending the useful life of the building and maximizing the return on investment. This adaptability also contributes to sustainability by reducing waste and resource consumption associated with building modifications.

Conclusion

Corrugated sandwich panels have emerged as a game-changer in improving site labor efficiency and overall construction productivity. Their streamlined installation process, enhanced safety features, and long-term benefits make them an ideal choice for modern construction projects. By simplifying assembly, reducing on-site fabrication, and minimizing the need for specialized equipment, these panels significantly cut down on labor hours and project timelines. The durability, energy efficiency, and adaptability of corrugated sandwich panels further contribute to long-term cost savings and sustainability. As the construction industry continues to evolve, the adoption of innovative materials like corrugated sandwich panels will play a crucial role in meeting the demands for faster, safer, and more efficient building practices.

Are you looking to enhance your next construction project with the efficiency and versatility of corrugated sandwich panels? Weifang Sandong Building Materials Co., Ltd. offers a wide range of high-quality, customizable corrugated sandwich panel solutions to meet your specific needs. Our panels combine superior insulation, fire retardancy, and aesthetic appeal, making them the ideal choice for various applications. Contact us today at info@sdqsc.com to discover how our corrugated sandwich panels can improve your site labor efficiency and overall project success.

FAQs

What are the main advantages of using corrugated sandwich panels in construction?

Corrugated sandwich panels offer improved site labor efficiency, enhanced insulation, fire retardancy, customizable designs, and long-term durability.

How do corrugated sandwich panels contribute to energy efficiency?

These panels provide excellent thermal insulation, reducing heating and cooling costs and improving overall building energy performance.

Can corrugated sandwich panels be customized for specific project needs?

Yes, Weifang Sandong Building Materials Co., Ltd. offers tailor-made solutions with customizable thicknesses, lengths, widths, and color options to suit various project requirements.

What materials are used in the construction of corrugated sandwich panels?

Corrugated sandwich panels typically use aluminum, steel, or stainless steel for the outer layers, with insulation cores made of polyurethane, polystyrene, or rock wool.

How can I learn more about using corrugated sandwich panels for my project?

For more information on our corrugated sandwich panel solutions, please contact us at info@sdqsc.com.

References

1. Moradibistouni, M., & Gjerde, M. (2021). Potential for Prefabrication to Enhance the New Zealand Construction Industry. Buildings, 11(6), 227.

2. Manalo, A. (2013). Structural behaviour of a prefabricated composite wall system made from rigid polyurethane foam and Magnesium Oxide board. Construction and Building Materials, 41, 642-653.

3. Wieland, H., Nicher, S., & Waltther, A. (2019). Sustainability assessment of sandwich panel construction. MATEC Web of Conferences, 282, 02077.

4. Lamnatou, C., Notton, G., Chemisana, D., & Cristofari, C. (2020). The environmental performance of a building-integrated solar thermal collector, based on multiple approaches and life-cycle impact assessment methodologies. Building and Environment, 169, 106547.

5. Panjehpour, M., Ali, A. A. A., & Voo, Y. L. (2013). Structural Insulated Panels: Past, Present, and Future. Journal of Engineering, Project, and Production Management, 3(1), 2-8.