Grasping PU Insulated Sandwich Panels and Moisture Risks

Composition and Benefits of PU Insulated Sandwich Panels

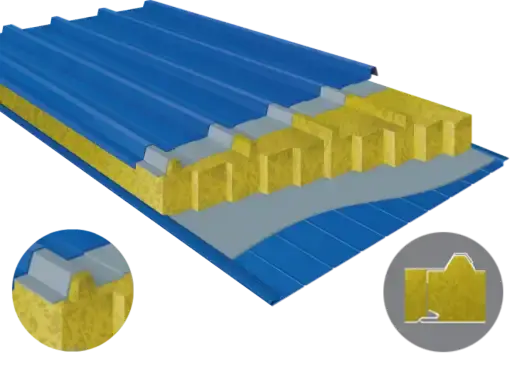

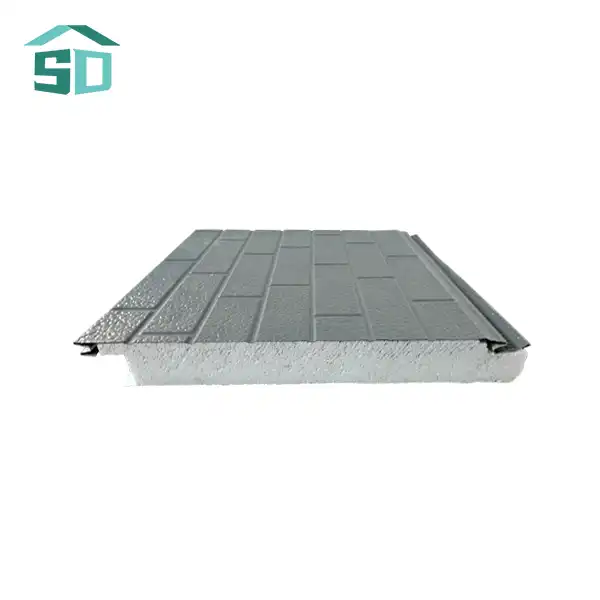

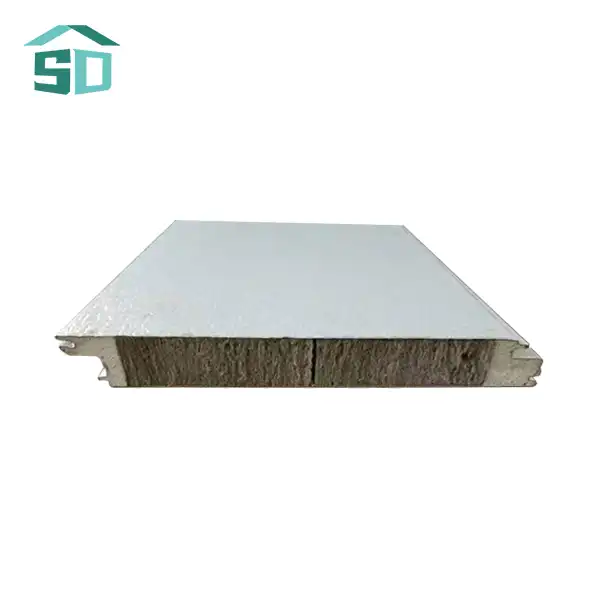

PU insulated sandwich panels are innovative building materials that offer exceptional thermal insulation properties. These panels consist of two metal facings with a polyurethane foam core, providing a lightweight yet robust solution for various construction applications. The unique composition of PU insulated sandwich panels allows for superior energy efficiency, fire resistance, and structural integrity.

One of the primary advantages of using PU insulated sandwich panels is their versatility. They can be utilized in diverse construction projects, ranging from residential complexes and offices to industrial facilities and cold storage units. The panels' adaptability makes them a popular choice among architects and builders seeking high-performance building materials.

Common Causes of Moisture Ingress in Panel Systems

Despite their numerous benefits, PU insulated sandwich panels can be susceptible to moisture ingress if not properly installed or maintained. Several factors can contribute to moisture-related issues:

- Inadequate sealing of joints and connections

- Improper fastening techniques

- Damage to panel surfaces during installation or transportation

- Lack of proper ventilation in the building envelope

- Poor design or specification of panel systems

Understanding these potential risks is essential for implementing effective installation practices that mitigate moisture ingress. PU insulated sandwich panels suppliers often provide guidelines and technical support to ensure optimal performance of their products.

Consequences of Moisture Infiltration

When moisture penetrates PU insulated sandwich panels, it can lead to a range of problems that compromise the building's integrity and performance:

- Reduced thermal insulation efficiency

- Corrosion of metal facings

- Delamination of panel layers

- Mold and mildew growth

- Structural weakening of the building envelope

These issues not only affect the longevity of the PU insulated sandwich panels but can also result in increased energy costs, poor indoor air quality, and potential health hazards for building occupants. Therefore, implementing proper installation practices is crucial for maintaining the panels' performance and ensuring a safe, comfortable environment.

Essential Installation Techniques for Moisture Prevention

Proper Joint Sealing and Panel Connections

One of the most critical aspects of installing PU insulated sandwich panels is ensuring proper sealing of joints and connections. This process involves using high-quality sealants and gaskets specifically designed for use with these panels. The sealants should be compatible with the panel materials and capable of withstanding temperature fluctuations and building movements.

When applying sealants, installers should pay close attention to the manufacturer's recommendations regarding application temperature, curing time, and surface preparation. It's essential to clean and dry all surfaces before applying sealants to ensure optimal adhesion. Additionally, installers should use backer rods or bond breaker tapes in deeper joints to control the sealant depth and prevent three-sided adhesion, which can lead to premature sealant failure.

Correct Fastening Methods and Hardware Selection

Choosing the right fasteners and employing proper fastening techniques is crucial for preventing moisture ingress in PU insulated sandwich panels. Installers should use corrosion-resistant fasteners that are compatible with the panel materials and designed to withstand the expected loads and environmental conditions.

When securing PU insulated sandwich panels, it's important to follow the manufacturer's recommendations for fastener spacing and placement. Over-tightening fasteners can compress the panel core and create potential weak points for moisture infiltration. Conversely, under-tightening can lead to inadequate sealing and panel movement. Using specialized tools, such as depth-sensing screw guns, can help ensure consistent and proper fastener installation.

Implementing Proper Flashing and Weatherproofing Techniques

Effective flashing and weatherproofing are essential for protecting PU insulated sandwich panels from moisture ingress. Installers should pay particular attention to vulnerable areas such as panel edges, corners, and penetrations. Properly designed and installed flashing helps direct water away from these critical points, preventing it from entering the building envelope.

When implementing weatherproofing techniques, consider the following best practices:

- Use high-quality, compatible flashing materials

- Ensure proper overlap of flashing components

- Apply weatherproof membranes or tapes at panel joints and intersections

- Incorporate drip edges and water diversion features where appropriate

- Seal all penetrations thoroughly, including fastener holes and utility openings

By meticulously addressing these aspects of installation, contractors can significantly reduce the risk of moisture ingress in PU insulated sandwich panel systems, ensuring long-term performance and durability.

Advanced Strategies for Long-Term Moisture Protection

Incorporating Vapor Barriers and Moisture Management Systems

To enhance the moisture resistance of PU insulated sandwich panels, incorporating vapor barriers and moisture management systems is highly recommended. These additional layers of protection help prevent water vapor from penetrating the panel core and compromising its insulation properties.

When selecting vapor barriers, it's crucial to choose materials with appropriate permeability ratings based on the building's climate and intended use. Proper installation of vapor barriers involves creating continuous, unbroken layers that effectively block moisture transmission. Pay special attention to sealing around penetrations and ensuring proper overlap at joints.

Moisture management systems, such as drainage planes or ventilated cavities, can further enhance the performance of PU insulated sandwich panels. These systems provide pathways for any moisture that does penetrate the exterior to drain away safely, preventing accumulation within the building envelope.

Optimizing Panel Layout and Design for Water Shedding

Thoughtful panel layout and design can significantly contribute to moisture prevention in PU insulated sandwich panel systems. When planning the installation, consider the following strategies:

- Orient panels to minimize horizontal joints, which are more prone to water infiltration

- Incorporate sloped surfaces or transitional flashing to direct water away from panel joints

- Design overhangs and drip edges to prevent water from running down panel faces

- Avoid creating areas where water can pool or collect on panel surfaces

- Plan for proper integration of panels with other building components, such as windows and doors

Implementing Regular Inspection and Maintenance Protocols

Even with the best installation practices, ongoing inspection and maintenance are crucial for ensuring the long-term performance of PU insulated sandwich panels. Establishing a regular inspection schedule allows building owners and managers to identify and address potential issues before they escalate into more significant problems.

Key aspects of an effective inspection and maintenance protocol include:

- Visual inspections of panel surfaces, joints, and fasteners for signs of damage or wear

- Checking sealants and gaskets for degradation or failure

- Monitoring for any signs of water staining or moisture accumulation on interior surfaces

- Cleaning and maintaining panel surfaces according to manufacturer recommendations

- Promptly repairing or replacing damaged components to prevent moisture ingress

Conclusion

Implementing best installation practices for PU insulated sandwich panels is crucial for preventing moisture ingress and ensuring long-term building performance. By focusing on proper joint sealing, correct fastening methods, and effective weatherproofing techniques, installers can create a robust moisture barrier. Advanced strategies such as incorporating vapor barriers, optimizing panel layout, and implementing regular maintenance protocols further enhance the panels' resistance to water infiltration.

For those seeking high-quality PU insulated sandwich panels and expert guidance on installation best practices, Weifang Sandong Building Materials Co., Ltd. stands ready to assist. As a leading PU insulated sandwich panels supplier, we offer a wide range of exterior cladding and facade solutions designed to meet the highest standards of performance and durability. To learn more about our products and services, or to discuss your specific project requirements, please don't hesitate to contact us at info@sdqsc.com.

FAQ

How often should PU insulated sandwich panels be inspected for moisture-related issues?

It's recommended to conduct visual inspections at least twice a year, with more frequent checks in harsh climates or after severe weather events.

Can PU insulated sandwich panels be retrofitted with additional moisture protection?

While it's best to implement moisture protection during initial installation, some retrofitting options exist, such as applying specialized coatings or adding external flashing. Consult with a professional for the best approach.

What are the signs of moisture ingress in PU insulated sandwich panels?

Signs may include visible water stains, bubbling or peeling of surface coatings, corrosion of metal facings, or a noticeable decrease in insulation performance.

References

1. Building Science Corporation. (2021). "Moisture Control for Building Envelopes."

2. International Code Council. (2018). "International Building Code."

3. National Institute of Building Sciences. (2020). "Whole Building Design Guide: Building Envelope Design Guide."

4. American Society for Testing and Materials. (2019). "ASTM E2112-19: Standard Practice for Installation of Exterior Windows, Doors and Skylights."

5. U.S. Department of Energy. (2022). "Building Envelope."