The Science Behind Polyurethane Foam Insulation Panels

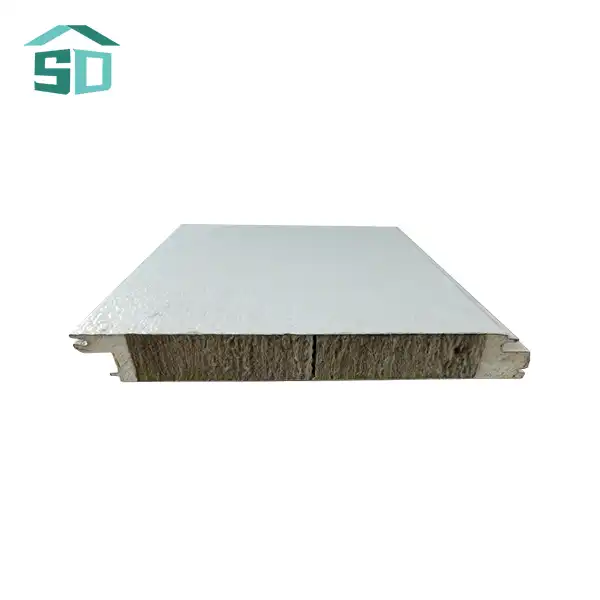

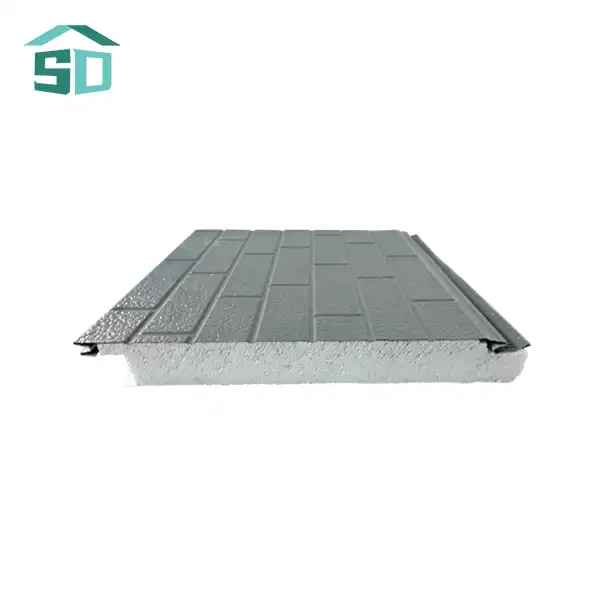

Polyurethane froth cover boards are built to maximize warm proficiency through their special composition and structure. The center of these boards is made from closed-cell polyurethane froth, which contains millions of modest discrete bubbles that act as obstructions to warm exchange. This cellular structure is key to the material's remarkable protection properties.

Thermal Conductivity and R-Value

One of the most critical aspects of any insulation material is its thermal conductivity, which measures how easily heat passes through it. Polyurethane foam panels boast an impressively low thermal conductivity of ≤ 0.022 W/(m·K). This translates to a high R-value, which indicates the material's resistance to heat flow. The higher the R-value, the better the insulation performance. Polyurethane foam panels typically offer R-values ranging from R-6 to R-7 per inch of thickness, outperforming many traditional insulation materials.

Density and Structural Integrity

The density of polyurethane foam insulation panels plays a crucial role in their performance and durability. With a density range of 32-40 kg/m³, these panels strike an optimal balance between insulation effectiveness and structural strength. This density ensures that the panels maintain their shape and insulating properties over time, even when subjected to various environmental stressors.

Fire Safety Considerations

Safety is paramount in construction, and polyurethane foam insulation panels address this concern with their fire-resistant properties. Classified as Class B1 fire-rated, these panels offer excellent resistance to flame spread and smoke development. This rating is crucial for meeting building codes and ensuring the safety of occupants in the event of a fire.

Advantages of Using Polyurethane Foam Insulation Panels

The adoption of polyurethane foam insulation panels in construction projects brings a multitude of benefits that extend beyond mere thermal insulation. These advantages contribute to the overall efficiency, sustainability, and longevity of buildings.

Energy Efficiency and Cost Savings

The superior insulating properties of polyurethane foam panels translate directly into significant energy savings. By effectively reducing heat transfer between the interior and exterior of a building, these panels minimize the workload on heating and cooling systems. This reduction in energy consumption not only lowers utility bills but also decreases the carbon footprint of the building, aligning with modern sustainability goals.

Moisture Resistance and Durability

Polyurethane foam insulation panels exhibit excellent resistance to moisture, which is crucial for maintaining the integrity of the building envelope. The closed-cell structure of the foam prevents water absorption, reducing the risk of mold growth and structural damage. This moisture resistance, combined with the material's inherent durability, ensures that the insulation remains effective for decades, typically exceeding 25 years with proper installation and maintenance.

Versatility in Application

The versatility of polyurethane foam insulation panels makes them suitable for a wide range of applications. Available in various thicknesses (50mm, 75mm, 100mm, 150mm) and a standard size of 1200mm x 2400mm, these panels can be easily customized to fit different project requirements. They are equally effective in new construction and renovation projects, finding use in residential buildings, commercial spaces, industrial facilities, and even transportation vehicles.

Installation and Integration of Polyurethane Foam Insulation Panels

The effectiveness of polyurethane foam insulation panels relies heavily on proper installation and integration into the building envelope. Understanding the installation process and considering key factors can ensure optimal performance and longevity of the insulation system.

Installation Process Overview

Installing polyurethane foam insulation panels is a relatively straightforward process that can be accomplished with careful planning and execution. The process typically involves the following steps:

- Surface Preparation: Ensuring the installation surface is clean, dry, and free of debris.

- Panel Cutting: Using appropriate tools to cut panels to the required size and shape.

- Adhesive Application: Applying a suitable adhesive to the back of the panel or directly to the wall surface.

- Panel Mounting: Pressing the panels firmly against the surface to ensure a tight fit.

- Sealing: Applying sealant to cover joints and edges for improved insulation and moisture resistance.

Proper installation is crucial for maximizing the insulation performance and ensuring the longevity of the system. It's often recommended to engage professional installers who are familiar with the specific requirements of polyurethane foam insulation panels.

Seamless Integration with Building Design

One of the advantages of polyurethane foam insulation panels is their ability to seamlessly integrate with various architectural designs. These panels can be customized in terms of color and surface treatment, offering options such as smooth or embossed finishes. This flexibility allows architects and designers to incorporate insulation without compromising on aesthetic appeal.

Complementary Accessories

To enhance the performance and installation of polyurethane foam insulation panels, a range of complementary accessories is available. These include:

- Specialized Adhesives: High-strength adhesives designed specifically for use with polyurethane foam panels.

- Sealants: Flexible sealants that ensure airtight installations and further improve insulation efficiency.

- Mechanical Fasteners: For additional security in panel installation, especially in areas subject to high winds or other environmental stresses.

These accessories work in concert with the panels to create a comprehensive insulation system that maximizes energy efficiency and durability.

Conclusion

Polyurethane foam insulation panels represent a significant advancement in building insulation technology. Their exceptional thermal properties, combined with durability, versatility, and ease of installation, make them an ideal choice for a wide range of construction projects. As the construction industry continues to prioritize energy efficiency and sustainable building practices, these panels offer a solution that meets both current needs and future expectations.

For those looking to enhance their building's energy performance and overall comfort, polyurethane foam insulation panels present a compelling option. To learn more about how these panels can benefit your specific project or to explore our range of exterior cladding and facade solutions, we invite you to contact us at info@sdqsc.com. Our team of experts is ready to provide you with the guidance and support needed to make informed decisions about your building's insulation needs.