The Science Behind Thermal Insulation Panels

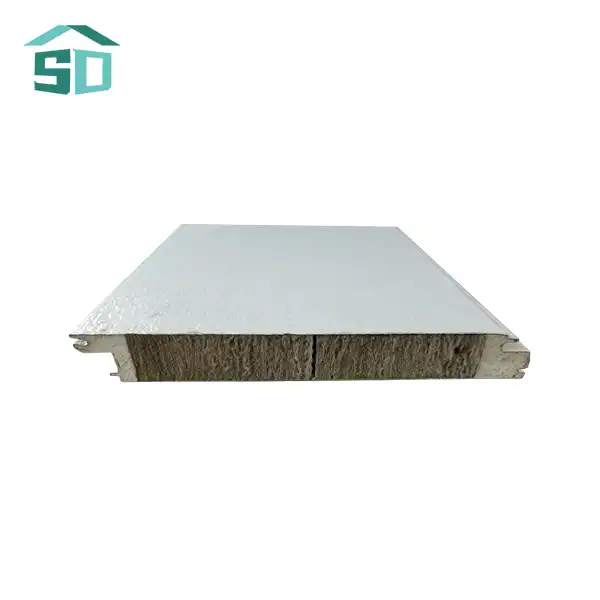

Thermal sequestration panels are sensations of ultramodern engineering, designed to combat the grim forces of nature. At their core, these panels use advanced accoutrements and cutting-edge technology to produce an impenetrable hedge against heat transfer. The secret lies in their multi-layered construction, which generally includes a high-performance separating core squeezed between durable surface layers.

Advanced Materials for Superior Performance

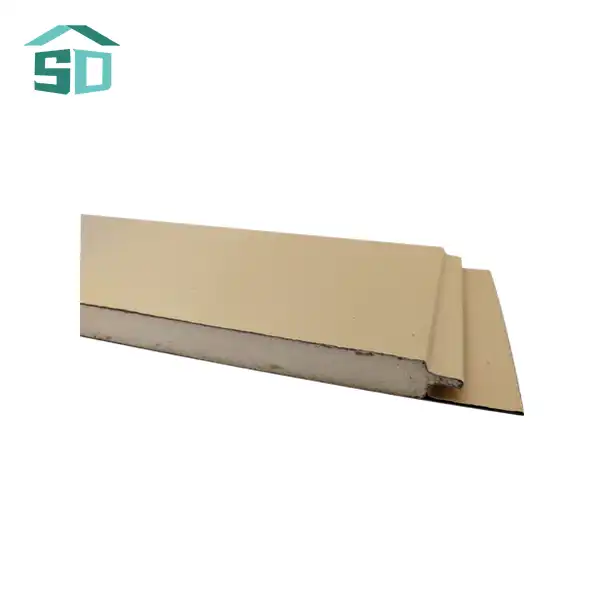

The insulating core of thermal panels is often composed of materials like polyurethane foam, which boasts an impressive thermal conductivity rating of just 0.018 W/m.k. This remarkably low thermal conductivity ensures that heat transfer is minimized to the greatest extent possible. The exterior layers, meanwhile, are crafted from robust materials such as steel or aluminum, with thicknesses ranging from 0.23mm to 0.27mm. These outer layers not only provide structural integrity but also offer protection against environmental factors like moisture and UV radiation.

Customizable Dimensions for Versatile Applications

One of the key advantages of thermal insulation panels is their adaptability to various architectural requirements. These panels can be customized in length to fit specific project needs. The thickness of the panels varies depending on their intended use, with interior panels typically measuring 10mm thick, while exterior panels range from 16mm to 20mm. The width of the panels is also tailored to the application, with exterior panels measuring 383mm wide and interior panels at 450mm wide. This flexibility in dimensions allows for seamless integration into diverse building designs, from residential complexes to commercial structures.

Withstanding Nature's Fury: Key Performance Metrics

When it comes to extreme weather conditions, thermal insulation panels are built to endure. Their impressive performance metrics are a testament to their durability and efficiency in the face of harsh environmental challenges.

Wind and Water Resistance

In regions prone to hurricanes or strong storms, wind resistance is a crucial factor. Thermal insulation panels boast a wind resistance rating of 8.0 kPa, ensuring they can withstand powerful gusts without compromising structural integrity. Additionally, these panels feature an exceptional waterproof rate of 0.0008, providing superior protection against rain and moisture infiltration. This combination of wind and water resistance makes thermal insulation panels an ideal choice for coastal areas or regions with high precipitation levels.

Fire Safety and Thermal Performance

Safety is paramount in building design, and thermal insulation panels excel in this aspect with a fire-protection rating of B1/B2. This classification indicates a high level of fire resistance, providing crucial time for evacuation in the event of a fire. In terms of thermal performance, these panels showcase a thermal resistance of 2.09 m²K/W, effectively minimizing heat transfer and maintaining comfortable indoor temperatures regardless of external conditions. The panels' compressive strength of 52.7 kPa further ensures their structural stability under various loads and pressures.

Installation and Long-Term Benefits

The effectiveness of thermal insulation panels is not solely dependent on their inherent properties but also on proper installation and long-term maintenance. Understanding the installation process and the enduring benefits of these panels is crucial for maximizing their performance.

Streamlined Installation Process

Installing thermal insulation panels is a relatively straightforward process, though it's recommended to consult with professionals for optimal results. The installation typically involves several key steps:

- Preparation: Ensuring the surface is clean, dry, and free of debris.

- Layout planning: Determining the optimal arrangement of panels according to design specifications.

- Cutting: Trimming panels to size using appropriate cutting tools.

- Attachment: Securing panels using mechanical fasteners or adhesive as per project requirements.

- Sealing: Applying sealant around edges to prevent moisture ingress and ensure a tight fit.

This simplified installation process contributes to faster construction times and reduced labor costs, making thermal insulation panels an attractive option for both new builds and renovations.

Long-Term Energy Efficiency and Cost Savings

The initial investment in high-quality thermal insulation panels pays dividends over time through enhanced energy efficiency and reduced utility costs. By creating an effective barrier against heat transfer, these panels significantly reduce the workload on HVAC systems, leading to lower energy consumption and decreased carbon emissions. In extreme weather conditions, this efficiency becomes even more pronounced, as the panels maintain stable indoor temperatures despite severe external fluctuations.

Moreover, the durability of thermal insulation panels ensures their performance remains consistent over many years, requiring minimal maintenance. Their resistance to environmental degradation, including corrosion and UV damage, further extends their lifespan, making them a cost-effective solution in the long run.

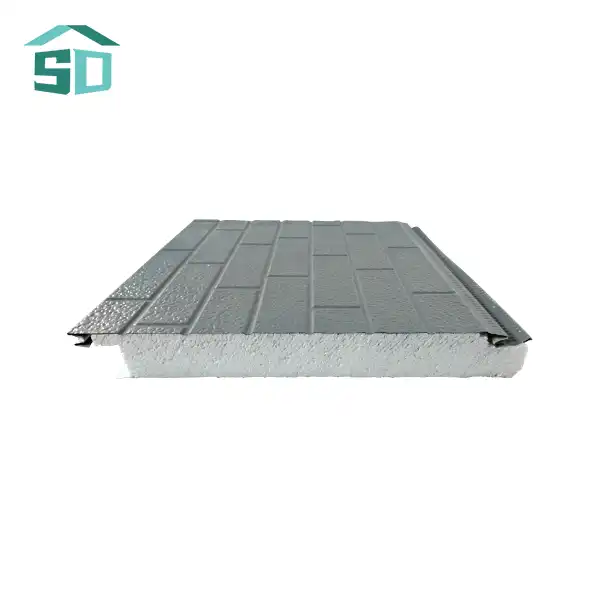

Versatility in Design and Application

Thermal insulation panels are not just about functionality; they also offer aesthetic versatility. Available in a wide range of colors and patterns, these panels can be tailored to suit any architectural style or design preference. This customizability makes them an ideal choice for various projects, from modern office buildings to historic renovations.

The adaptability of thermal insulation panels extends to their application in different types of structures. They find use in residential complexes, offices, villas, gardens, municipal buildings, and even security kiosks. This versatility, combined with their superior performance, makes thermal insulation panels a preferred choice among architects and builders looking to balance form and function in their projects.

Conclusion

In the face of extreme weather conditions, thermal insulation panels stand as a beacon of innovation in building technology. Their unmatched durability, superior insulation properties, and versatile applications make them an indispensable component in modern construction. As we continue to grapple with the challenges posed by climate change, the adoption of such advanced building materials becomes not just a choice but a necessity.

For those looking to enhance their building's resilience against extreme weather while simultaneously improving energy efficiency, thermal insulation panels offer a compelling solution. To learn more about how these panels can benefit your specific project or to explore our range of exterior cladding and facade solutions, we invite you to contact us at info@sdqsc.com. Our team of experts is ready to assist you in creating buildings that are not just structures but fortresses against the elements.