The Energy Efficiency Revolution: How Prefabricated Thermal Panels Are Changing the Game?

Unparalleled Thermal Performance

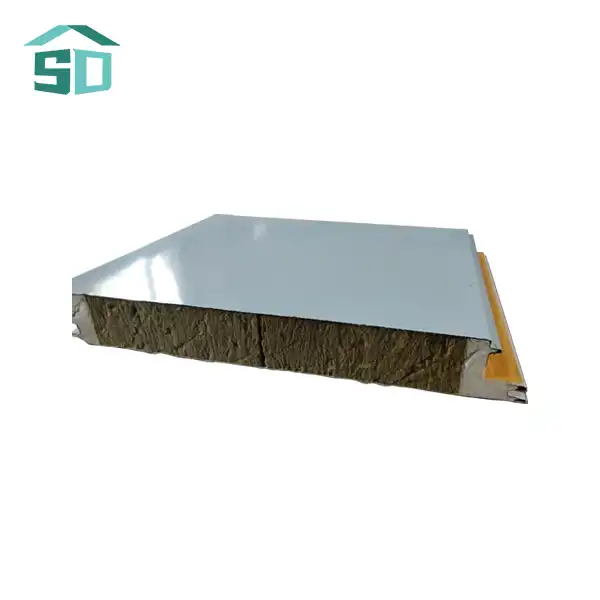

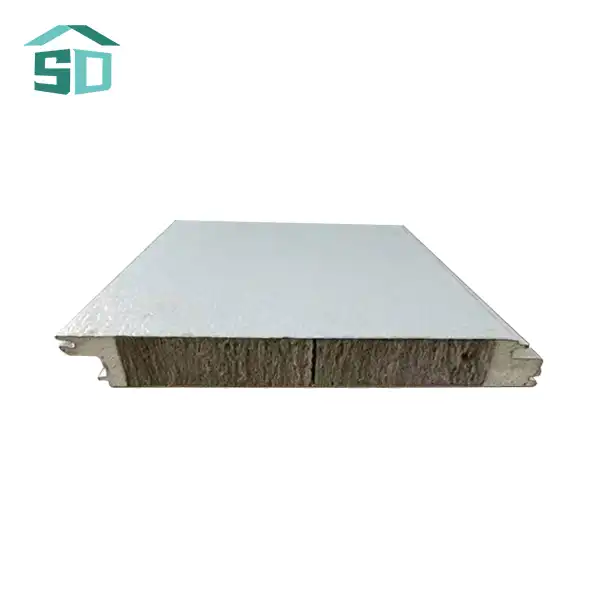

Prefabricated thermal panels are at the forefront of energy-efficient construction, offering unmatched insulation capabilities. These panels, crafted with advanced materials like polyurethane, polystyrene, rock wool, or glass wool, provide exceptional thermal resistance. The high-performance insulation core, sandwiched between durable exterior and interior facings, creates a formidable barrier against heat transfer. This superior thermal efficiency translates to significant energy savings, keeping interiors cooler in summer and warmer in winter, thus reducing the load on HVAC systems and slashing energy bills.

Seamless Integration for Maximum Efficiency

One of the key advantages of prefabricated thermal panels is their ability to create a continuous insulation envelope around a building. Unlike traditional construction methods that can leave thermal bridges, these panels offer seamless integration, eliminating gaps and weak points in the building's thermal barrier. This comprehensive approach to insulation ensures that the entire structure benefits from optimal thermal performance, further enhancing energy efficiency and occupant comfort.

Sustainable Materials and Manufacturing

The revolution in sustainable construction is not just about the end product but also the manufacturing process. Prefabricated thermal panels are often produced using eco-friendly materials and energy-efficient manufacturing techniques. Many manufacturers, including Weifang Sandong Building Materials Co., Ltd., are committed to using recyclable materials and reducing waste in the production process. This commitment to sustainability extends the panels' environmental benefits beyond their energy-saving properties, contributing to a more holistic approach to green building practices.

Streamlined Construction: The Efficiency of Prefabricated Thermal Panels

Rapid Installation and Reduced Labor Costs

The prefabrication of thermal panels brings a new level of efficiency to the construction site. These panels are designed for quick and easy installation, significantly reducing on-site construction time. The lightweight yet robust nature of prefabricated panels allows for easier handling and faster assembly. This streamlined process not only accelerates project timelines but also minimizes labor costs, making sustainable construction more accessible and economically viable for a wider range of projects.

Precision Engineering for Reduced Waste

Prefabricated thermal panels are manufactured in controlled factory environments, ensuring precise dimensions and high quality. This precision engineering results in minimal on-site adjustments and reduces construction waste. The panels are custom-made to fit specific project requirements, eliminating the need for extensive cutting and modification during installation. This reduction in waste not only contributes to the sustainability of the construction process but also leads to cleaner, more efficient job sites.

Weather-Independent Construction

Traditional construction methods are often at the mercy of weather conditions, leading to delays and increased costs. Prefabricated thermal panels offer a solution to this challenge. The majority of the panel production occurs in a controlled factory environment, unaffected by external weather conditions. This allows for consistent production schedules and quality control. Once on-site, the quick installation process of these panels minimizes exposure to adverse weather, enabling construction to progress more smoothly and predictably.

Versatility and Aesthetics: The Design Flexibility of Prefabricated Thermal Panels

Customizable Solutions for Diverse Architectural Needs

Prefabricated thermal panels are not a one-size-fits-all solution; they offer remarkable versatility to meet diverse architectural requirements. Available in a range of materials including aluminum, steel, and stainless steel, these panels can be customized in size, thickness, and finish to suit specific project needs. This flexibility allows architects and designers to achieve their creative vision while maintaining the highest standards of thermal efficiency and structural integrity.

Aesthetic Appeal and Durability

Gone are the days when energy efficiency meant compromising on aesthetics. Modern prefabricated thermal panels come in a wide array of colors, textures, and finishes, allowing for seamless integration with various architectural styles. Whether it's a sleek, modern facade or a more traditional appearance, these panels can be tailored to enhance the visual appeal of any structure. Moreover, their durability and weather resistance ensure that the building's appearance remains pristine for years to come, withstanding UV radiation, corrosion, and moisture.

Multifunctional Applications

The versatility of prefabricated thermal panels extends beyond just exterior walls. These innovative products find applications in various construction elements, including roofs, interior partitions, and even specialized structures like cold storage facilities. Their adaptability makes them suitable for a wide range of projects, from residential complexes and office buildings to industrial facilities and public institutions. This multifunctionality not only simplifies the construction process but also ensures consistent thermal performance throughout the entire building envelope.

Conclusion

Prefabricated thermal panels are indeed revolutionizing sustainable construction, offering a powerful combination of energy efficiency, construction speed, and design flexibility. As the construction industry continues to evolve towards more sustainable practices, these innovative panels are poised to play an increasingly crucial role. Their ability to significantly reduce energy consumption, streamline the building process, and offer versatile design options makes them an invaluable asset in creating environmentally responsible and aesthetically pleasing structures.

For those looking to harness the benefits of prefabricated thermal panels in their next construction project, Weifang Sandong Building Materials Co., Ltd. offers cutting-edge solutions tailored to your specific needs. To learn more about our products and how they can elevate your sustainable building efforts, please contact us at info@sdqsc.com.

FAQ

What materials are used in prefabricated thermal panels?

Prefabricated thermal panels typically use materials like aluminum, steel, or stainless steel for the outer layers, with insulation cores made of polyurethane, polystyrene, rock wool, or glass wool.

How do prefabricated thermal panels contribute to energy efficiency?

These panels provide superior insulation, creating a continuous thermal barrier that significantly reduces heat transfer, thereby lowering energy consumption for heating and cooling.

Are prefabricated thermal panels suitable for all types of buildings?

Yes, they are versatile and can be used in various structures, including residential, commercial, industrial, and specialized buildings like cold storage facilities.

References

1.U.S. Department of Energy. (2023). "Energy Efficiency in Buildings."

2.American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2022). "ASHRAE Handbook - Fundamentals."

3.International Code Council. (2023). "International Energy Conservation Code."

4.Building Science Corporation. (2022). "Guide to Insulating Sheathing."

5.National Institute of Building Sciences. (2023). "Whole Building Design Guide."