The Science Behind Fire-Resistant Insulated Sandwich Panels

Composition and Structure

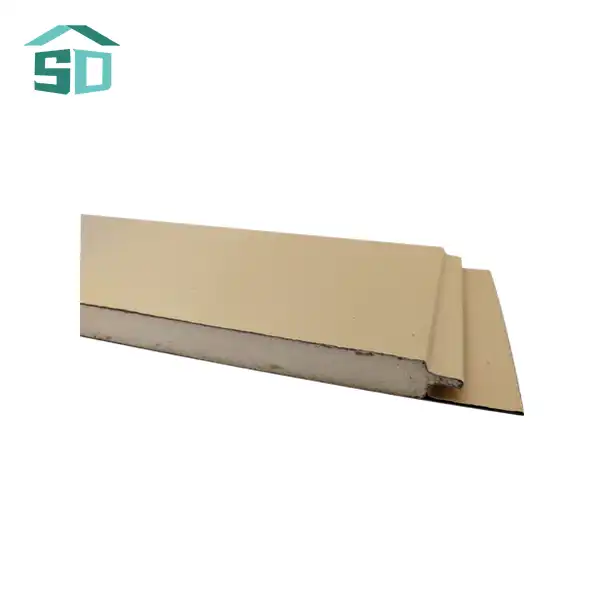

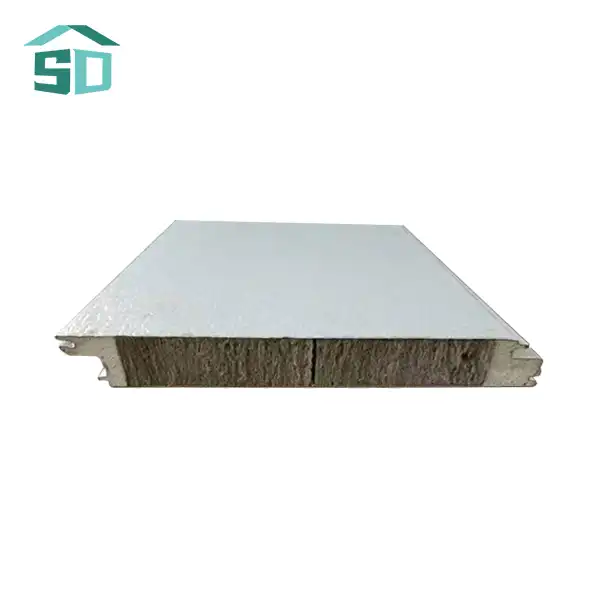

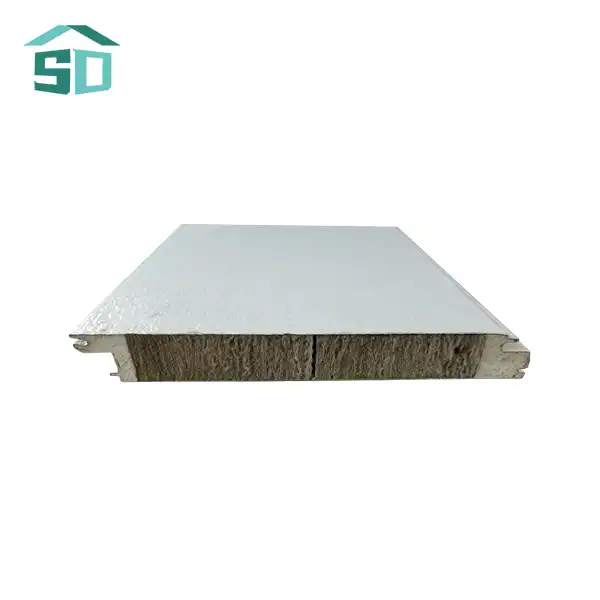

Fire-resistant insulated sandwich panels are engineered marvels, consisting of three primary components: two metal facings and an insulating core. The metal facings, typically made of aluminum, steel, stainless steel, or copper, provide structural strength and durability. These facings are available in various thicknesses and can be customized with different surface treatments such as coating, painting, or anodizing to meet specific aesthetic requirements.

The heart of the panel lies in its insulating core, which is crucial for both thermal performance and fire resistance. Common core materials include polyurethane, polystyrene, rock wool, and glass wool. Each material offers unique properties, but for fire-resistant panels, materials like rock wool and specially formulated polyurethane are often preferred due to their superior fire-retardant characteristics.

Fire Resistance Mechanisms

The fire resistance of these insulated sandwich panels is achieved through a combination of material properties and design features. The non-combustible nature of the metal facings provides an initial barrier against fire spread. The insulating core, especially when made of materials like rock wool, acts as a fire barrier, slowing down heat transfer and preventing the rapid spread of flames.

Advanced fire-resistant panels often incorporate intumescent coatings or additives in the core material. These substances expand when exposed to high temperatures, creating a char layer that further insulates the panel and protects the structure behind it. This multi-layered approach to fire resistance ensures that the panels meet stringent fire safety standards, providing crucial time for evacuation and fire suppression efforts in the event of a fire.

Benefits Beyond Fire Safety

Energy Efficiency and Thermal Performance

While fire resistance is a paramount feature, insulated sandwich panels offer a plethora of additional benefits. Their superior thermal insulation properties significantly reduce heat transfer, leading to improved energy efficiency in buildings. This translates to lower heating and cooling costs, making these panels an economically sound choice for long-term building operations.

The thermal performance of these panels is measured by their U-value, which indicates the rate of heat transfer through the material. With options ranging from 50mm to 150mm in thickness, these panels can be tailored to meet specific insulation requirements for different climates and building types. This adaptability ensures optimal energy performance across various environmental conditions.

Durability and Low Maintenance

Fire-resistant insulated sandwich panels are designed for longevity. The metal facings provide excellent resistance to weathering, corrosion, and mechanical damage. This durability translates to reduced maintenance costs over the life of the building. The panels are easy to clean and maintain, requiring minimal upkeep to retain their appearance and performance over time.

Moreover, the panels' resistance to moisture and pests further enhances their durability. Unlike traditional building materials that may deteriorate due to water ingress or insect infestation, these panels maintain their structural integrity and insulating properties for extended periods, ensuring a longer lifespan for the building envelope.

Versatility in Application and Design

Architectural Flexibility

One of the most compelling aspects of fire-resistant insulated sandwich panels is their versatility in architectural applications. These panels can be used in a wide array of building types, from residential complexes and offices to industrial warehouses and transportation facilities. Their adaptability makes them suitable for both new construction projects and renovations of existing structures.

Architects appreciate the design flexibility offered by these panels. With customizable colors, finishes, and surface treatments, the panels can be tailored to match any architectural style or aesthetic preference. This versatility allows for creative expression while maintaining the essential functional properties of fire resistance and insulation.

Ease of Installation and Cost-Effectiveness

The establishment handle for fire-resistant protective sandwich boards is strikingly proficient, contributing to quicker development timelines and diminished labor costs. The boards are ordinarily lightweight but fundamentally sound, making them simple to handle and introduce. This effectiveness not only quickens and extends completion but also minimizes disturbance in redesign scenarios.

From a taken-a-toll point of view, whereas the introductory speculation in these boards may be higher than a few conventional building materials, the long-term benefits frequently result in critical taken-a-toll investment funds. Diminished vitality utilization, lower upkeep necessities, moved forward indoor consolation, upgraded property esteem, and expanded building life expectancy all contribute to a favorable return on venture over time, making them a shrewd and maintainable choice for both private and commercial applications.

Conclusion

Fire-resistant insulated sandwich panels represent a significant advancement in building technology, offering a unique combination of safety, efficiency, and versatility. As the construction industry continues to evolve towards more sustainable and resilient building practices, these panels are poised to play an increasingly important role. Their ability to meet stringent fire safety standards while providing excellent thermal insulation and design flexibility makes them an attractive option for architects, builders, and property owners alike.

For those interested in exploring the potential of fire-resistant insulated sandwich panels for their next project, Weifang Sandong Building Materials Co., Ltd. offers a comprehensive range of high-quality options. To learn more about our products and how they can enhance your building's safety and efficiency, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.