The Science Behind Metal Carved Boards' Energy Efficiency

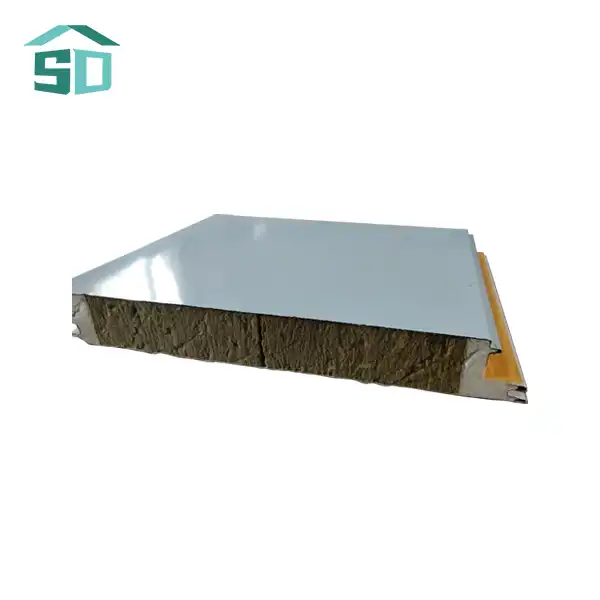

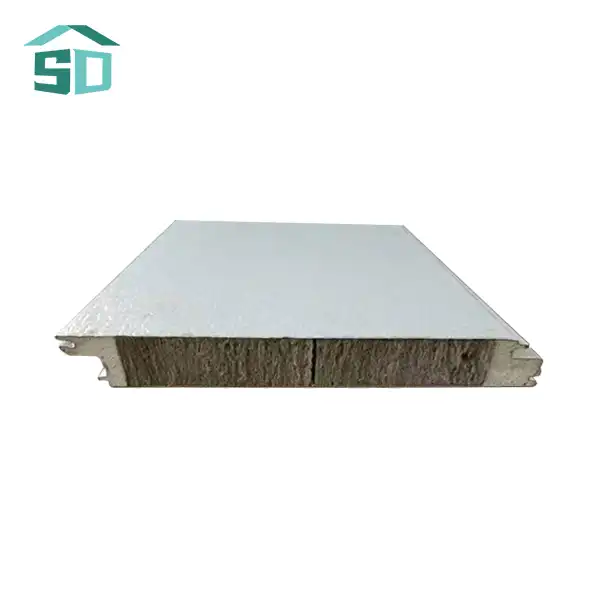

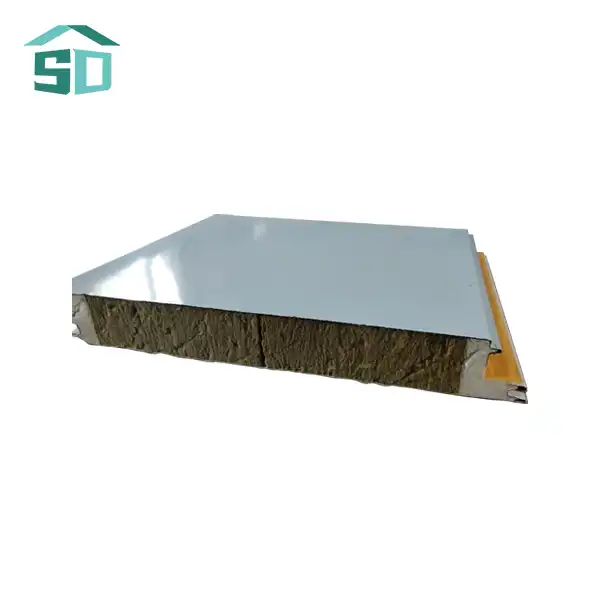

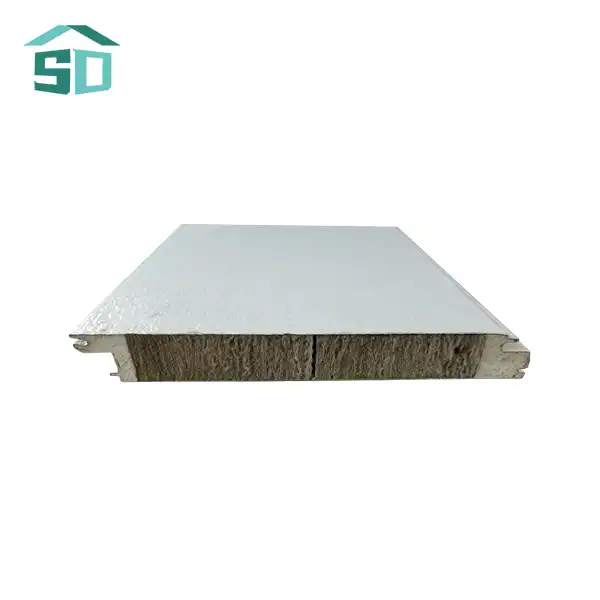

Metal carved boards are not just aesthetically pleasing; they're also powerful tools for energy conservation. The secret lies in their innovative design and material composition. These boards typically consist of a metal surface with intricate carvings, backed by insulating materials that work together to create a formidable barrier against heat transfer.

The thermal performance of metal carved boards is truly impressive. With a thermal conductivity of just 0.018W/m.k, these boards excel at minimizing heat flow. This low thermal conductivity means that very little heat can pass through the material, effectively keeping the interior of a building insulated from external temperature fluctuations.

Moreover, the thermal resistance (R-value) of metal carved boards stands at an impressive 2.09m2k/w. This high R-value indicates superior insulating properties, as it measures the board's ability to resist heat flow. The higher the R-value, the better the insulation, and metal carved boards certainly deliver in this aspect.

The Role of Carvings in Energy Efficiency

You might wonder how the carved designs contribute to energy efficiency. The answer lies in the physics of heat transfer. The carvings create a textured surface that increases the overall surface area of the board. This increased surface area allows for better heat dissipation, helping to regulate temperature more effectively.

Additionally, the carved patterns can create small air pockets, which act as additional insulating layers. Air is a poor conductor of heat, so these pockets further enhance the board's ability to resist heat transfer, contributing to its overall energy efficiency.

Practical Applications of Metal Carved Boards for Energy Savings

The energy-efficient properties of metal carved boards make them versatile solutions for various architectural and design applications. Their ability to improve a building's thermal performance translates into tangible benefits for both residential and commercial structures.

In residential settings, metal carved boards can be used as decorative wall cladding that doubles as an energy-saving feature. When applied to exterior walls, these boards create an additional insulating layer that helps maintain a comfortable indoor temperature with less reliance on heating and cooling systems.

For commercial buildings, metal carved boards offer an opportunity to combine aesthetic appeal with practical energy management. Office buildings, hotels, and retail spaces can benefit from the boards' ability to reduce heat gain in summer and heat loss in winter, potentially leading to significant savings on energy bills.

Customization for Optimal Performance

One of the key advantages of metal carved boards is their customizability. The boards can be tailored to specific project requirements, with options for different thicknesses and surface materials. For interior applications, boards with a thickness of 10mm are typically used, while exterior applications may call for thicker boards of 16mm or 20mm.

The thickness of surface materials can also be adjusted, ranging from 0.23mm to 0.27mm, allowing for fine-tuning of the board's performance characteristics. This flexibility enables architects and builders to optimize the energy efficiency of their designs while meeting specific aesthetic and functional goals.

Long-Term Benefits and Sustainability of Metal Carved Boards

Investing in metal carved boards for energy efficiency is not just about immediate gains; it's a long-term strategy for sustainable building practices. These boards offer durability and longevity that contribute to their overall value proposition.

With excellent weather resistance and corrosion resistance, metal carved boards maintain their performance over time. This durability means that the energy-saving benefits continue year after year, without significant degradation. The boards' ability to withstand various environmental conditions, including high winds (with a wind resistance of 8.0 Kpa), ensures that they remain effective insulators throughout their lifespan.

Environmental Impact and Recyclability

Beyond their energy-saving capabilities, metal carved boards align with eco-friendly construction practices. Many of these boards are manufactured using recyclable materials, promoting sustainability in the building industry. At the end of their lifecycle, the metal components can often be recycled, reducing waste and environmental impact.

The boards' contribution to reduced energy consumption also translates to a lower carbon footprint for buildings. By decreasing the need for artificial heating and cooling, metal carved boards help minimize greenhouse gas emissions associated with energy production.

Fire Safety and Additional Benefits

While energy efficiency is a primary benefit, metal carved boards offer additional advantages that enhance their overall value. Their fire-protection rating of B1/B2 provides an extra layer of safety for buildings. This fire resistance is crucial in modern construction, where safety regulations are increasingly stringent.

Furthermore, with a waterproof rate of 0.0008, these boards offer excellent protection against moisture intrusion. This feature not only contributes to the longevity of the building envelope but also helps maintain the insulation's effectiveness, as dry insulation performs better than damp materials.

The compressive strength of 52.7kpa ensures that metal carved boards can withstand physical stresses without compromising their insulating properties. This robustness makes them suitable for a wide range of applications, from decorative interior panels to load-bearing exterior cladding.

Conclusion

Metal carved boards represent a harmonious blend of form and function in modern architecture. Their ability to significantly improve energy efficiency while offering aesthetic versatility makes them an invaluable asset in sustainable building design. By providing superior thermal insulation, weather resistance, and long-term durability, these boards contribute to reduced energy consumption, lower operational costs, and a smaller environmental footprint.

As the construction industry continues to prioritize energy-efficient solutions, metal carved boards stand out as a practical and visually appealing option. Their customizable nature allows for seamless integration into diverse architectural styles, proving that energy efficiency doesn't have to come at the expense of design.

For those looking to enhance their building's energy performance while adding a touch of elegance, metal carved boards offer a compelling solution. To learn more about how these innovative products can benefit your next project, don't hesitate to reach out to us at info@sdqsc.com. Our team of experts is ready to help you explore the full potential of metal carved boards in creating energy-efficient, beautiful spaces.

FAQs

What makes metal carved boards energy-efficient?

Metal carved boards improve energy efficiency through their low thermal conductivity (0.018W/m.k) and high thermal resistance (2.09m2k/w), which minimize heat transfer and maintain stable indoor temperatures.

Can metal carved boards be used for both interior and exterior applications?

Yes, metal carved boards are versatile and can be used for both interior (10mm thickness) and exterior (16mm or 20mm thickness) applications, offering energy-saving benefits in various settings.

Are metal carved boards environmentally friendly?

Metal carved boards are often made from recyclable materials and contribute to reduced energy consumption in buildings, aligning with eco-friendly construction practices.

References

1.American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2017). ASHRAE Handbook - Fundamentals. Atlanta, GA: ASHRAE.

2.U.S. Department of Energy. (2022). Energy Saver: Insulation.

3.International Code Council. (2021). International Energy Conservation Code. Washington, D.C.: ICC.