The Science Behind PU Insulated Sandwich Panels

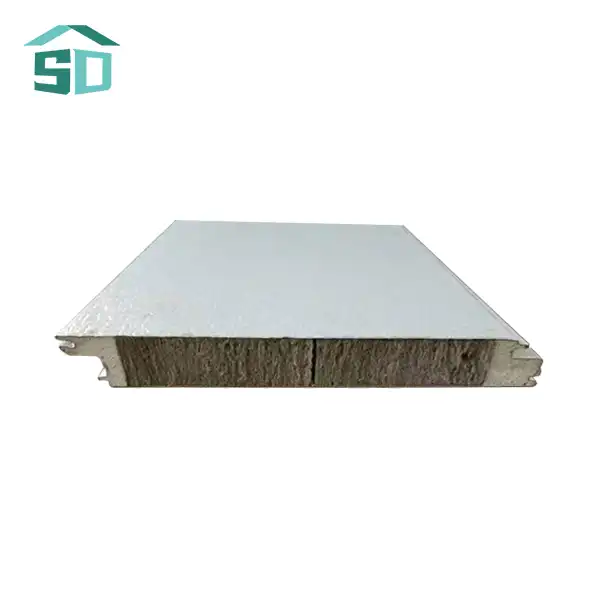

PU insulated sandwich panels are engineered with a core of polyurethane foam sandwiched between two metal facings, typically steel or aluminum. This unique composition creates a powerful barrier against heat transfer, effectively maintaining the desired temperature within cold storage facilities. The closed-cell structure of the polyurethane foam provides exceptional thermal resistance, significantly reducing heat flow and minimizing energy loss.

The thermal conductivity of PU insulated sandwich panels is remarkably low, with K-values ranging from 0.022 to 0.028 W/mK. This superior insulation performance translates to substantial energy savings and improved temperature stability in cold storage applications. The panels' ability to maintain consistent temperatures is crucial for preserving the quality and safety of perishable goods, making them indispensable in the food and pharmaceutical industries.

Moisture Resistance and Vapor Barrier Properties

One of the key advantages of PU insulated sandwich panels in cold storage is their excellent moisture resistance. The closed-cell structure of the polyurethane foam core acts as an effective vapor barrier, preventing moisture penetration and condensation issues. This property is particularly valuable in cold storage environments where temperature fluctuations can lead to moisture buildup and potential damage to stored products.

The panels' moisture-resistant qualities also contribute to their long-term durability and performance. By preventing water ingress, PU insulated sandwich panels maintain their insulation properties and structural integrity over time, ensuring consistent temperature control and reducing maintenance requirements in cold storage facilities.

Structural Advantages for Cold Storage Applications

PU insulated sandwich panels offer remarkable structural benefits that make them ideal for cold storage construction. The panels' high strength-to-weight ratio allows for the creation of large, open spaces without the need for additional supporting structures. This design flexibility enables efficient use of storage space and facilitates the movement of goods within the facility.

The panels' lightweight nature simplifies installation processes, reducing construction time and labor costs. Despite their light weight, PU insulated sandwich panels exhibit excellent load-bearing capacity, capable of supporting roof loads, wind loads, and the weight of suspended equipment commonly found in cold storage environments.

Fire Safety and Regulatory Compliance

Safety is paramount in cold storage facilities, and PU insulated sandwich panels meet rigorous fire safety standards. Many manufacturers offer panels with fire-retardant additives that achieve a B1 fire protection level, ensuring compliance with building codes and regulations. The panels' fire-resistant properties provide crucial time for evacuation and fire suppression in the event of an emergency, enhancing overall safety in cold storage operations.

Additionally, PU insulated sandwich panels can be engineered to meet specific industry standards and regulatory requirements for cold storage facilities, including food safety and pharmaceutical storage guidelines. This compliance ensures that the panels not only provide excellent insulation but also contribute to maintaining the integrity and quality of stored products.

Energy Efficiency and Sustainability in Cold Storage

The superior insulation properties of PU insulated sandwich panels translate directly into significant energy savings for cold storage facilities. By minimizing heat transfer and maintaining stable temperatures, these panels reduce the workload on refrigeration systems, leading to lower energy consumption and operational costs. The energy efficiency of PU insulated sandwich panels contributes to a reduced carbon footprint, aligning with sustainability goals and environmental regulations.

Furthermore, the longevity and durability of PU insulated sandwich panels contribute to their overall sustainability. With proper maintenance, these panels can maintain their performance characteristics for decades, reducing the need for frequent replacements and minimizing waste. The potential for recycling and repurposing the metal facings at the end of the panels' lifecycle adds to their eco-friendly profile.

Customization and Versatility

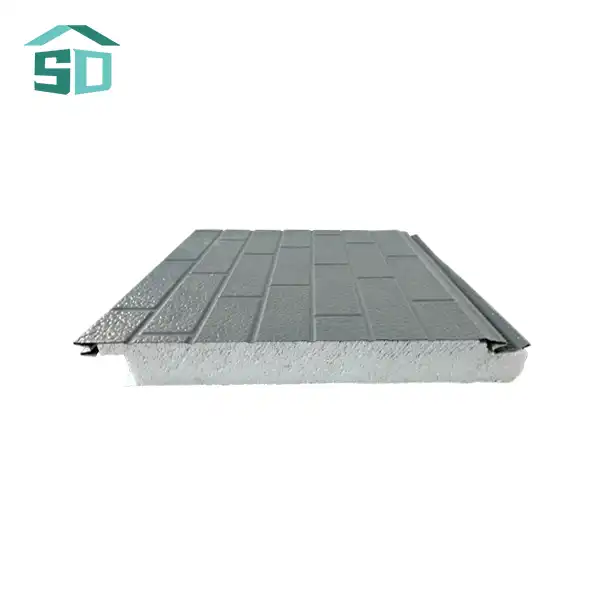

PU insulated sandwich panels offer a high degree of customization, allowing cold storage facility designers to tailor solutions to specific requirements. Panels can be manufactured in various thicknesses to achieve desired R-values, and the metal facings can be finished in a range of colors and textures to meet aesthetic preferences. This versatility extends to the panels' application in different cold storage environments, from small walk-in coolers to expansive distribution centers.

The adaptability of PU insulated sandwich panels also facilitates future modifications and expansions of cold storage facilities. Their modular nature allows for easy reconfiguration of spaces, addition of new sections, or repurposing of existing structures, providing long-term flexibility for businesses in the cold storage industry.

Conclusion

PU insulated sandwich panels have revolutionized cold storage construction, offering a perfect balance of thermal efficiency, structural integrity, and versatility. Their superior insulation properties, coupled with moisture resistance and fire safety features, make them an indispensable component in modern cold storage facilities. The panels' contribution to energy efficiency and sustainability aligns with current industry trends towards environmentally responsible practices. As the demand for efficient cold storage solutions continues to grow, PU insulated sandwich panels stand out as a reliable and high-performance choice for maintaining optimal storage conditions.

At Weifang Sandong Building Materials Co., Ltd., we specialize in providing top-quality PU insulated sandwich panels for cold storage applications. Our panels are engineered to meet the most stringent requirements of the cold storage industry, ensuring superior performance and longevity. Whether you're planning a new cold storage facility or upgrading an existing one, our team of experts is ready to assist you in finding the perfect insulation solution. Contact us today at info@sdqsc.com to learn more about how our PU insulated sandwich panels can elevate your cold storage operations to new heights of efficiency and reliability.

FAQ

What is the typical lifespan of PU insulated sandwich panels in cold storage applications?

With proper installation and maintenance, PU insulated sandwich panels can last 30 years or more in cold storage environments.

Can PU insulated sandwich panels be used in both refrigerated and frozen storage areas?

Yes, these panels are suitable for a wide range of temperatures, from chilled storage to deep freeze applications.

How do PU insulated sandwich panels compare to traditional insulation methods for cold storage?

PU insulated sandwich panels offer superior insulation, faster installation, and better space efficiency compared to traditional methods like fiberglass or spray foam insulation.

References

1.Thermal Insulation Association of Canada. (2021). "Polyurethane and Polyisocyanurate Insulation."

2.International Association for Cold Storage Construction. (2020). "Cold Storage Design and Construction Guide."

3.Journal of Construction and Building Materials. (2019). "Performance of Polyurethane Sandwich Panels in Cold Storage Applications."

4.Energy Efficiency in Industrial Processes. (2022). "Energy Savings in Cold Storage Facilities."

5.Fire Safety Journal. (2021). "Fire Performance of Insulated Sandwich Panels in Cold Storage Buildings."