Fireproof insulation panels are an important safety investment for modern factories because they protect against heat loss and fire better than other materials. Specialized walls made of rock wool, polyurethane, and metal construction make shields that stop flames from spreading and keep temperatures at the right level. When working in an industrial setting with lots of hot equipment and a high risk of fire, these panels are very important for keeping people and valuable gear safe. It has become standard for safety-conscious makers who put regulatory compliance and keeping operations running smoothly to build their factories with fireproof insulation panels.

Understanding Fireproof Insulation Panels and Their Role in Factories

Modern industrial facilities face unprecedented challenges in maintaining safe, energy-efficient operations while meeting stringent regulatory requirements. Fire-resistant insulation solutions have evolved to address these complex needs through innovative material combinations and engineering excellence.

Advanced Material Composition for Industrial Safety

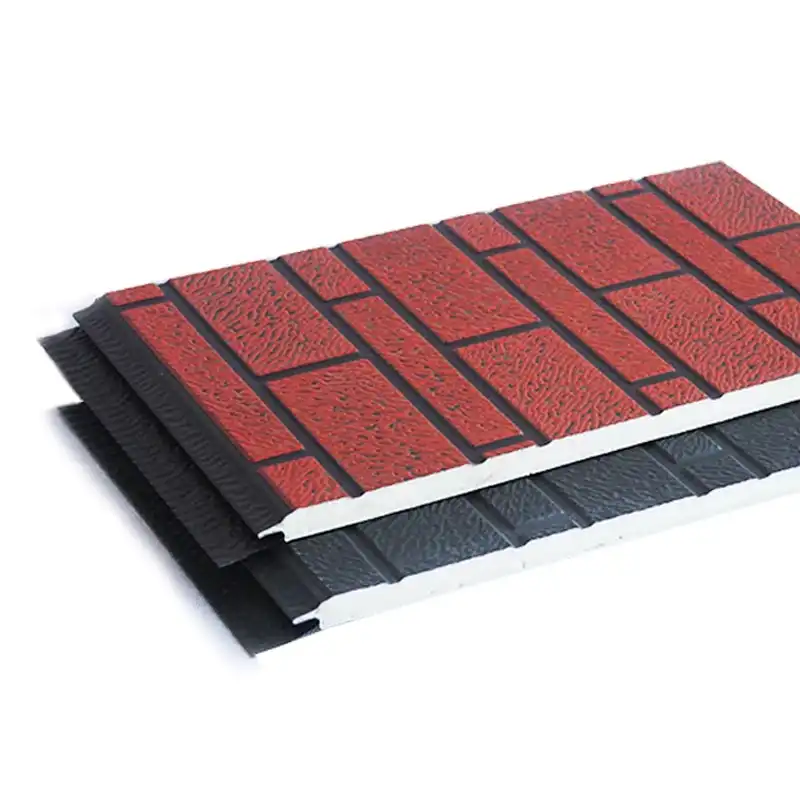

Fireproof insulation panels are made of complex mixtures of materials that give them great heat protection and flame control. Many high-performance panels use rock wool as their core insulation because it naturally doesn't catch fire and has melting points above 1000°C. This mineral-based insulation keeps the structure strong even in very hot weather by stopping thermal bridges and keeping protection shields in place. The steel and metal layers on the outside support the structure and make it more resistant to fire. Special surface treatments, like anodizing and protective coating processes, are used to make these metal parts more resistant to rust and increase their service life.

When you put these two things together, you get screens that can handle working in factory settings where the temperature changes, there is moisture, and there is mechanical stress. If made correctly, polyurethane and foam insulation layers are very good at keeping heat in and fire-resistant qualities. Because these materials have higher R-values, they help manufacturing sites save energy and keep temperatures stable. Manufacturers can make panels that work best for certain uses and performance needs by combining different insulation materials.

Critical Applications in Manufacturing Environments

Industrial buildings need fire safety plans that cover a wide range of operating areas and types of equipment. Installing fire-resistant panels that keep possible ignition sources out of machinery shelters while still allowing repair workers to reach them is very helpful. These programs keep expensive tools safe and make workplaces safe for people to work in. Panels can also be used as fire shields and heat protection in structural wall uses, which are very important.

A lot of the time, processes in factories use high temperatures, chemical reactions, or electrical equipment that makes heat. Fire-resistant panels that are fixed on the wall make safe shields that stop fires from spreading between work areas while keeping energy costs low. Ceiling structures protect from above and stop fires from spreading through building systems. Complex ceiling structures that hold electricity systems, HVAC equipment, and process pipes are common in industrial buildings. Fire-resistant ceiling panels keep these important systems safe and make upkeep and changes easy to get to.

Comparison of Fireproof Insulation Panels Versus Traditional Insulation Solutions

In order to choose the right insulation materials, you need to know how current fire-resistant walls work differently from older ones. This comparison shows that modern panel systems have big benefits that make them worth the money.

Superior Safety Performance and Durability

In order to save money or keep the heat in, traditional insulation materials often put fire safety at risk. While traditional fiberglass insulation does a good job of keeping heat in, it doesn't offer much in the way of fire safety and can even help a fire grow in some situations. When exposed to high temperatures, standard foam insulation materials may give off harmful gases, adding to the dangers. Engineered mixtures of materials and strict testing procedures make fire-resistant walls safer than other types. According to EN 13501-1 standards, these panels usually get A1 or A2 fire ratings, which mean they don't add much to the fire load and are very resistant to flames.

The multi-layer design keeps fires from spreading and keeps the structure strong in case of an emergency. Durability benefits become clear when service life is stretched and upkeep needs are decreased. When traditional insulation materials are exposed to industrial conditions like changing temperatures, wetness, and chemical fumes, they may break down. Unlike other types of panels, fire-resistant panels keep working well for a long time, which cuts down on repair costs and downtime.

Installation Efficiency and Long-term Value

Installing panel systems and standard insulating methods are very different from one another. Putting up conventional insulation usually takes more than one step, safety walls, and special tools that make the job take longer and cost more to do. Traditional insulation projects can be held up by weather issues, especially in industrial settings with limited installation dates. Fire-resistant walls make installation easier by having features built in and making it easier to connect them.

Custom sizes up to 3000mm x 1200mm cut down on the need to cut and the amount of waste that is made. Standardized binding systems and edge treatments make sure that the quality of the work is always the same and cut down on the need for skilled labor. The benefits of energy efficiency build over time, leading to big cost saves that cover the initial investment. Better scores for thermal conductivity mean that factories don't have to use as much energy to heat and cool. The ability to insulate sound makes workplaces quieter, which boosts output and worker happiness.

Selecting the Right Fireproof Insulation Panels for Your Factory

Effective procurement strategies begin with comprehensive assessment of facility requirements, operational conditions, and regulatory obligations. This systematic approach ensures optimal panel selection that meets both immediate needs and long-term operational goals.

Critical Evaluation Criteria for Industrial Applications

The needs for thermal protection are very different in different plant areas and uses. Panels with high R-values and stable temperatures are needed in process areas that make a lot of heat. In storage places, fire resistance may be more important than high heat performance. This lets cost savings happen without affecting safety goals. The standards for fire ratings depend on local building codes, insurance rules, and rules that are specific to the business. Facilities that work with flammable materials or methods need to have better fire resistance scores than general assembly activities.

If you know about these needs early on in the buying process, you can avoid expensive changes to the specifications and delays in the project. The makeup of a material affects both how well it works and how well it works with other building systems. Aluminum panels don't rust easily, so they're great for places near the coast or where chemicals are processed. When mechanical stress or shaking is present, steel panels offer better structural strength. Stainless steel choices are the most durable and can withstand harsh situations.

Thickness and Customization Considerations

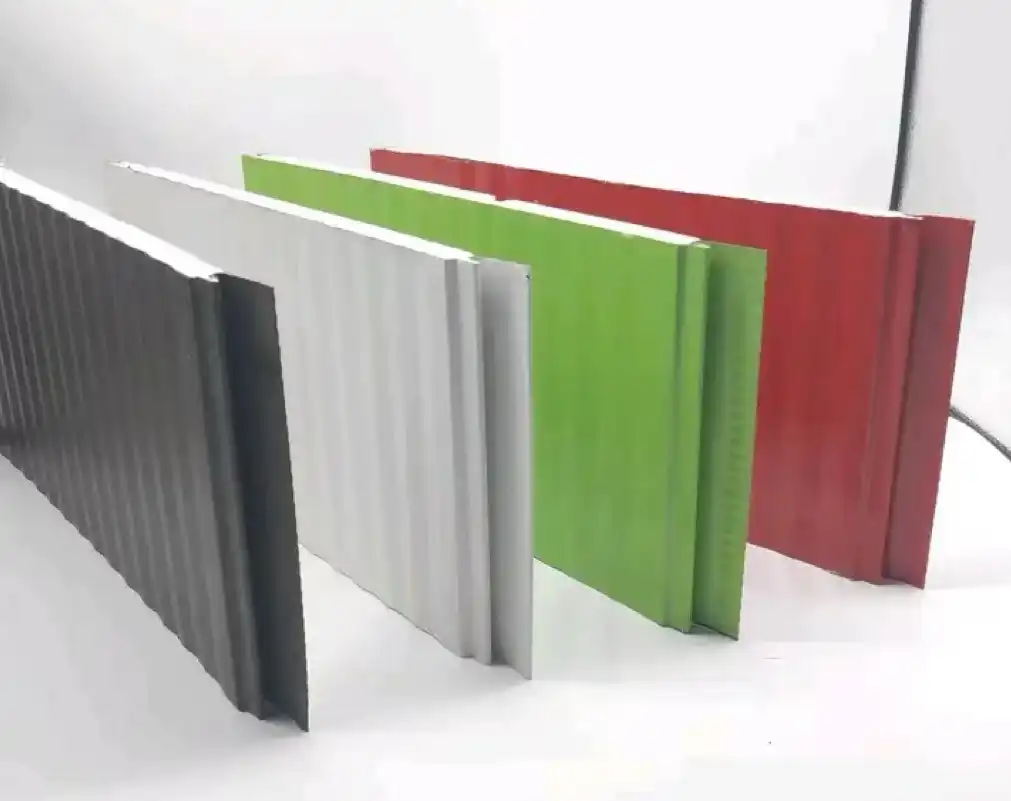

The choice of panel width affects both how well it keeps heat in and how easy it is to install. Standard sizes such as 50mm, 75mm, and 100mm can be used for most workplace tasks without breaking the bank. Although thicker panels provide better insulation, the structure may need to be changed to suit the thicker walls. Surface treatment choices have a big effect on how panels look, how long they last, and how often they need to be maintained. Coatings can be used to protect against weather and improve the look of things while still keeping their fire-resistant qualities. Painting choices let you match colors to the overall style of the building and add extra safety benefits.

Customization lets you get the best results for your project while also taking into account physical limitations. Custom color matching makes sure that the new look fits in with the current look of the building. Different edge finishes and fastening methods are available to meet specific fitting or structural needs. How to Install and Take Care of Fireproof Insulation Panels in Industrial Settings Professional fitting techniques improve the performance of the panel while making sure that safety rules and maker specs are followed. These steps take into account common installation problems and set up upkeep schedules that keep things working well for a long time.

Installation and Maintenance Guide for Fireproof Insulation Panels in Industrial Settings

Professional installation practices maximize panel performance while ensuring compliance with safety regulations and manufacturer specifications. These procedures address common installation challenges while establishing maintenance protocols that preserve long-term effectiveness.

Comprehensive Installation Procedures

Preparing the surface is the most important step in installing panels correctly. To make sure proper bonding and support, existing surfaces must be clean, dry, and physically sound. Contamination problems like oil leftovers, chemical stains, and rust that need special cleaning methods are common in industrial settings. A structural evaluation makes sure that the structure can support the panel loads and connection needs. When installing things in an industrial building, the way it's built may need to be changed because of things like shaking, heat growth, and entry issues.

Before work starts, a professional review finds any problems that might come up. For the safety of workers and the quality of the panels, cutting and fitting processes need the right tools and safety gear. Cutting tools made for industry make sure that the sides are clean and keep their fire resistance. Wearing the right safety gear keeps you from getting hurt by sharp edges and flying particles that are created when cutting.

Fastening and Sealing Protocols

Attachment methods need to be able to meet both short-term installation needs and long-term performance goals. Specialized screws made for different base materials make sure that the panels stay together securely while still keeping their structure. When you choose the right design and spacing between your fasteners, you can spread the loads out evenly and avoid stress areas. Sealing around the edges and holes in panels keeps them fireproof and keeps the heat inside. High-quality lubricants made just for fire-rated parts keep the safety performance while allowing for normal building movement.

The edge trim parts give the job a professional look and make it harder for water and mechanical damage to get in. Quality checking methods make sure that the work follows the rules and look for possible problems before the project is finished. Panels meet performance requirements by measuring gaps, inspecting fasteners, and checking the alignment. Keeping records of the materials and steps used for fitting helps with guarantee claims and plans for future upkeep.

Maintenance and Longevity Strategies

Regular inspection schedules identify deterioration before it compromises panel performance or safety characteristics. Visual inspections can reveal damage from mechanical impact, thermal stress, or environmental exposure that requires attention. Early intervention prevents minor issues from developing into costly replacement requirements.

Cleaning procedures maintain panel appearance and performance while preventing contamination buildup. Industrial environments often generate airborne contaminants that accumulate on panel surfaces over time. Appropriate cleaning methods preserve surface treatments and fire resistance properties while removing operational residues.

Repair protocols address common damage types while maintaining fire-rated assembly integrity. Minor dents, scratches, or seal failures can often be repaired without panel replacement. Understanding repair limitations helps facility managers make appropriate decisions about repair versus replacement.

Sustainability and Safety: Future-Proofing Your Factory with Fireproof Insulation Panels

Modern manufacturing facilities increasingly prioritize environmental responsibility alongside operational efficiency and safety performance. Advanced fire-resistant panel systems address these priorities through sustainable materials, energy efficiency, and long-term durability characteristics.

Environmental Benefits and Sustainable Practices

Contemporary fireproof insulation panels incorporate recyclable materials and sustainable manufacturing processes that reduce environmental impact throughout product lifecycles. Aluminum and steel components maintain value through recycling programs that recover substantial material value at end-of-service. This circular economy approach reduces waste generation while supporting sustainable business practices.

Energy efficiency contributions extend beyond direct thermal performance to include reduced heating and cooling loads that decrease carbon footprint. Superior insulation properties minimize energy consumption while maintaining comfortable working conditions. These benefits accumulate over panel service life, generating substantial environmental and economic returns on investment.

Manufacturing processes increasingly emphasize sustainable practices including reduced energy consumption, waste minimization, and responsible sourcing. Leading manufacturers implement environmental management systems that track and optimize resource utilization throughout production cycles. These practices ensure products contribute to sustainable building goals while maintaining performance standards.

Regulatory Compliance and Future Readiness

Building codes continue evolving toward stricter fire safety and energy efficiency requirements that affect industrial facility design and renovation projects. Investing in high-performance fire-resistant panels ensures compliance with current regulations while providing margin for future requirement changes. This forward-looking approach prevents costly retrofits and ensures continued operational compliance.

International certification standards including ISO, CE, and UL provide third-party verification of performance claims and quality management systems. These certifications demonstrate commitment to quality while facilitating international business relationships and regulatory compliance. Certified products often qualify for insurance discounts and regulatory incentives that improve project economics.

Emerging technologies including smart insulation systems and integrated monitoring capabilities represent the future direction of industrial fire protection systems. Advanced panels may incorporate sensors, communication capabilities, and adaptive properties that enhance safety and efficiency. Selecting systems with upgrade compatibility ensures long-term value and future readiness.

Conclusion

Fireproof insulation panels have become indispensable components of modern industrial facility design, offering unmatched combination of safety performance, energy efficiency, and operational reliability. These advanced systems provide superior protection against fire hazards while contributing to sustainable manufacturing practices through reduced energy consumption and long service life. The investment in high-quality fire-resistant panels delivers measurable returns through lower insurance costs, reduced energy bills, and enhanced operational safety that protects both personnel and valuable equipment. As regulatory requirements continue evolving and sustainability becomes increasingly important, fire-resistant insulation panels represent essential infrastructure that supports both current operations and future business success.

FAQ

What materials are used in fireproof insulation panels?

Modern fire-resistant panels combine multiple materials including rock wool or glass wool insulation cores with aluminum, steel, or stainless steel outer layers. The insulation materials provide thermal resistance and fire suppression capabilities, while metallic components offer structural strength and additional fire resistance. Surface treatments including coating, painting, and anodizing enhance durability and appearance while maintaining safety performance.

How do fireproof panels compare to traditional insulation in terms of energy efficiency?

Fire-resistant panels typically provide superior energy efficiency through enhanced thermal conductivity ratings and reduced thermal bridging. The integrated design eliminates gaps and thermal bridges common in traditional insulation installations, resulting in better overall thermal performance. Sound insulation properties create additional comfort benefits while reducing energy loads required for climate control systems.

What certifications should I look for when selecting fireproof insulation panels?

Essential certifications include fire ratings according to EN 13501-1 standards, with A1, A2, B1, or B2 ratings depending on application requirements. ISO quality management certifications demonstrate consistent manufacturing processes, while CE marking ensures European compliance. UL listings provide verification for North American markets, and additional certifications may be required for specific industries or applications.

Can fireproof insulation panels be customized for specific factory requirements?

Yes, reputable manufacturers offer extensive customization options including custom sizes up to 3000mm x 1200mm, various thickness options from 50mm to 100mm, and multiple material combinations. Color matching capabilities ensure integration with existing facility design, while specialized edge treatments and fastening systems accommodate unique installation requirements. OEM services provide completely customized solutions for specific industrial applications.

What maintenance is required for fireproof insulation panels?

Maintenance requirements are minimal but important for long-term performance. Regular visual inspections identify damage from mechanical impact or environmental exposure that requires attention. Cleaning procedures remove industrial contaminants while preserving surface treatments and fire resistance properties. Seal inspection and replacement around panel edges maintain fire barriers and thermal efficiency over extended service periods.

Partner with Weifang Sandong Building Materials Co.,Ltd. for Premium Fireproof Insulation Solutions

Weifang Sandong Building Materials Co.,Ltd. stands as your trusted fireproof insulation panels manufacturer, delivering superior quality products that meet the demanding requirements of modern industrial facilities. Our comprehensive product portfolio includes customizable panels with fire ratings from A1 to B2, multiple thickness options, and diverse material combinations optimized for industrial applications. With ISO, CE, and UL certifications, our panels ensure compliance with international safety standards while providing exceptional thermal performance and durability. Contact our expert team at info@sdqsc.com to discuss your specific requirements and discover how our fireproof insulation panels can enhance your facility's safety, efficiency, and operational performance.

References

1.National Fire Protection Association. "NFPA 220: Standard on Types of Building Construction." National Fire Protection Association Standards, 2018.

2.International Building Code Council. "Chapter 7: Fire and Smoke Protection Features." International Building Code, 2021 Edition.

3.American Society for Testing and Materials. "ASTM E119: Standard Test Methods for Fire Tests of Building Construction and Materials." ASTM International Standards, 2020.

4.European Committee for Standardization. "EN 13501-1: Fire Classification of Construction Products and Building Elements." European Standards, 2019.

5.Factory Mutual Global Research. "Industrial Fire Protection Systems: Performance Standards and Installation Guidelines." FM Global Property Loss Prevention Data Sheets, 2020.

6.United States Department of Labor. "Occupational Safety and Health Standards: Fire Protection." OSHA Technical Manual, Section III, Chapter 6, 2019.

.webp)

.webp)

_1769676626972.jpg)

.webp)

_1769676705124.jpg)