Understanding Metal Sandwich Panels: Composition and Applications

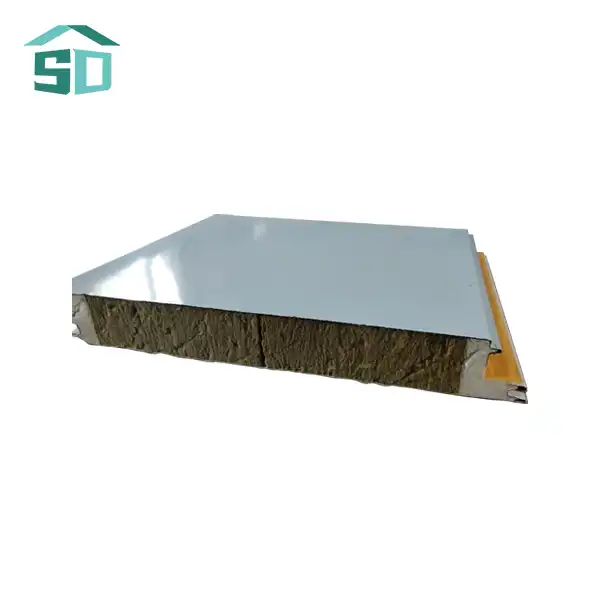

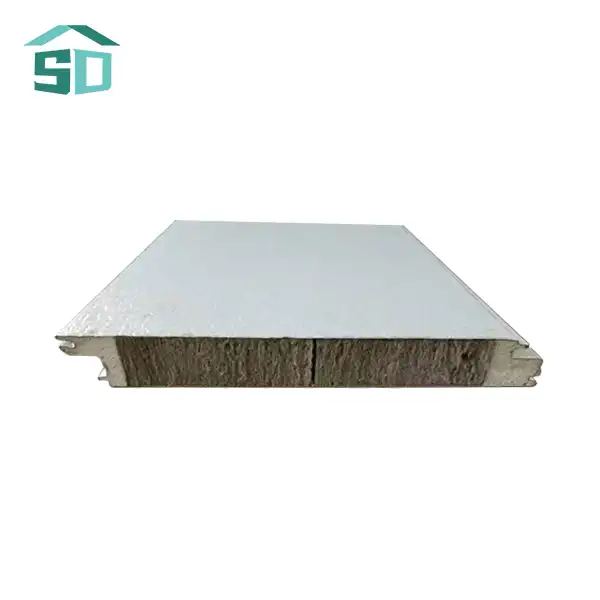

Metal sandwich panels are a marvel of modern construction, combining strength, insulation, and aesthetics in a single product. These panels consist of two metal facings with an insulating core sandwiched between them. The metal facings can be made from various materials, including aluminum, steel, stainless steel, or copper, each offering unique properties suited to different applications.

The core material plays a crucial role in the panel's performance. Common insulation materials include polyurethane, polystyrene, rock wool, and glass wool. Each core material offers different thermal and acoustic insulation properties, fire resistance, and overall panel weight. The choice of core material depends on the specific requirements of the project, such as energy efficiency, fire safety, or sound dampening needs.

Versatility in Construction

The versatility of metal sandwich panels makes them a popular choice in various construction sectors. They find applications in:

- Residential complexes

- Office buildings

- Industrial facilities

- Cold storage units

- Agricultural structures

- Retail spaces

Their adaptability extends to both exterior and interior applications. As exterior cladding, these panels provide a sleek, modern appearance while offering superior weather resistance and insulation. Internally, they can be used for partitions, ceilings, and even decorative elements, contributing to the overall aesthetic and functional aspects of a space.

Customization Options

One of the key advantages of metal sandwich panels is their high degree of customizability. Manufacturers offer a wide range of options to suit various project requirements:

- Size: Panels can be customized to specific dimensions, reducing on-site cutting and waste.

- Thickness: Options typically range from 30mm to 150mm, allowing for tailored insulation performance.

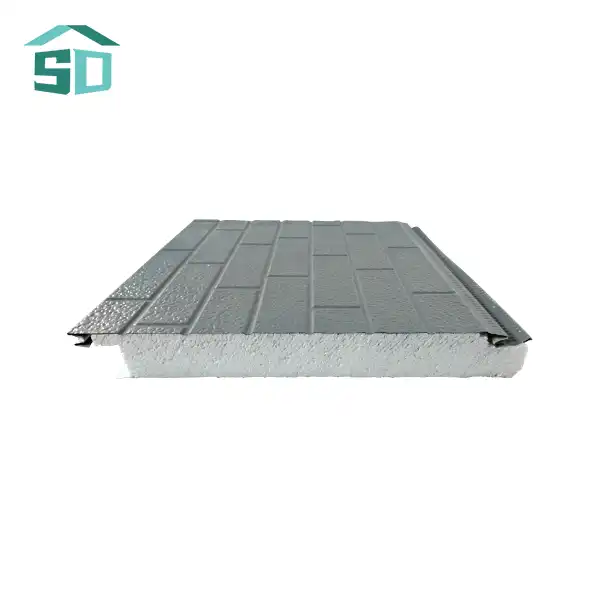

- Color and Finish: A diverse palette of colors and surface treatments (including coating, painting, and anodizing) enables architects to achieve their desired aesthetic vision.

- Profile: Various surface profiles can be incorporated to add visual interest or improve panel rigidity.

Proper Techniques for Lifting and Handling Metal Sandwich Panels

The process of lifting and handling metal sandwich panels requires precision and care to maintain the integrity of the panels and ensure worker safety. Here are some essential techniques and considerations:

Manual Lifting Techniques

For smaller panels that can be safely handled by workers:

- Use proper lifting posture: Bend at the knees, keep the back straight, and lift with the legs.

- Wear protective gear: Gloves with a good grip, safety shoes, and appropriate clothing.

- Coordinate movements: When multiple workers are involved, ensure clear communication and synchronized lifting.

- Avoid twisting: Turn with your feet, not your waist, when changing direction while carrying a panel.

Mechanical Lifting Methods

For larger or heavier panels, mechanical assistance is crucial:

- Vacuum lifters: These devices use suction cups to grip the panel surface, distributing the weight evenly and preventing damage.

- Panel lifters: Specially designed tools that clamp onto the edges of the panel, providing a secure grip for lifting and maneuvering.

- Crane or forklift assistance: For very large panels or when working at heights, cranes or forklifts with appropriate attachments can be used.

Safety Precautions

Prioritizing safety is paramount when handling metal sandwich panels:

- Assess the environment: Ensure the work area is clear of obstacles and hazards.

- Check weather conditions: Wind can significantly affect panel handling, especially for larger pieces.

- Use proper equipment: Ensure all lifting equipment is in good condition and rated for the panel weight.

- Train workers: Provide comprehensive training on lifting techniques and equipment operation.

- Plan the lift: Before attempting to move a panel, plan the route and identify any potential challenges.

Installation Best Practices for Metal Sandwich Panels

Proper installation is crucial to maximize the benefits of metal sandwich panels. Following best practices ensures longevity, optimal performance, and aesthetic appeal.

Pre-Installation Preparations

Before beginning the installation process:

- Inspect panels: Check for any damage or defects upon delivery.

- Acclimate panels: Allow panels to adjust to the installation environment for at least 24 hours.

- Prepare the surface: Ensure the installation surface is clean, dry, and level.

- Gather tools: Have all necessary tools and accessories ready, including fasteners, sealants, and cutting equipment.

Installation Process

The installation process typically involves the following steps:

1. Measure and mark: Accurately measure and mark the areas where panels will be installed.

2. Cut panels: If necessary, cut panels to size using appropriate tools that won't damage the panel edges or surface.

3. Apply sealant: Use high-quality sealants at panel joints to ensure water and airtightness.

4. Secure panels: Attach panels to the structure using recommended fasteners, ensuring they are level and properly aligned.

5. Install accessories: Add corner pieces, trims, and other accessories for a finished look and additional weather protection.

Post-Installation Care

After installation, proper care helps maintain the panels' appearance and performance:

- Clean panels: Regular cleaning with mild detergent and water helps preserve the panel's appearance.

- Inspect regularly: Conduct periodic inspections to check for any signs of damage or wear.

- Address issues promptly: If any problems are identified, address them quickly to prevent further damage.

Conclusion

Metal sandwich panels offer a compelling combination of strength, insulation, and aesthetic appeal, making them a popular choice in modern construction. Proper lifting, handling, and installation techniques are crucial to fully leverage the benefits of these versatile building materials. By following the guidelines outlined in this article, construction professionals can ensure safe handling, efficient installation, and optimal performance of metal sandwich panels in their projects.

For more information about our range of metal sandwich panels and expert advice on their application, please don't hesitate to contact us at info@sdqsc.com. Our team is ready to assist you in selecting the perfect panels for your next construction project.