Understanding the Causes of Aluminum Siding Chalking

Chalking in aluminum siding is primarily caused by the gradual breakdown of the paint's resin binder due to UV radiation and other environmental factors. As the resin deteriorates, the pigment particles in the paint become loose and form a powdery residue on the surface. This process is exacerbated by factors such as:

- Prolonged sun exposure

- Extreme temperature fluctuations

- Atmospheric pollutants

While all exterior paints will eventually chalk to some degree, the rate and severity of chalking can vary depending on the quality of the paint used on the aluminum metal siding panels. Lower-quality paints or those not specifically formulated for use on aluminum surfaces tend to chalk more quickly and severely.

Impact on Aesthetics and Performance

The chalking process can significantly impact both the appearance and performance of aluminum siding:

- Fading and discoloration of the siding's original color

- Accumulation of chalky residue on surrounding surfaces

- Reduced reflectivity, potentially affecting energy efficiency

- Decreased protection against moisture and other environmental elements

In severe cases, extensive chalking can lead to the erosion of the protective paint layer, potentially exposing the underlying aluminum to oxidation and corrosion.

Prevention and Maintenance Strategies for Aluminum Siding

While chalking is a natural process, there are several strategies that can be employed to minimize its occurrence and maintain the appearance and performance of aluminum metal siding panels:

Quality Paint Selection

Choosing high-quality, strong paints particularly outlined for utilize on aluminum surfaces can essentially decrease the rate of chalking. These specialized paints often incorporate advanced resins and UV-resistant additives specifically formulated to bond effectively with aluminum substrates. By enhancing the durability of the coating, these paints help maintain color integrity and surface gloss over extended periods, ultimately reducing maintenance requirements and preserving the visual appeal of aluminum siding in demanding outdoor environments.

Regular Cleaning and Maintenance

Implementing a routine cleaning schedule is an essential practice to help preserve the aesthetic quality of aluminum siding panels. Using a soft brush or cloth with a mild detergent solution effectively removes accumulated dirt, debris, and loose chalk particles without scratching or damaging the painted finish. Regular cleaning not only improves the appearance of the siding but also minimizes the long-term effects of chalking and weather-related wear.

Protective Coatings

Applying a clear protective coating on top of painted aluminum siding serves as an added layer of defense against harmful UV radiation, moisture, and pollutants. These transparent coatings help slow down the degradation of the paint layer underneath, maintaining color vibrancy and surface gloss for longer. By extending the service life of the siding's finish, protective coatings offer both aesthetic benefits and cost-effective, long-term performance enhancements.

Professional Repainting

When chalking becomes severe and significantly affects the siding's appearance, professional repainting may be necessary to restore its look and protective qualities. This process typically involves thorough cleaning, removing loose paint and accumulated chalk, followed by applying a fresh coat of high-quality, aluminum-compatible paint. Professional repainting not only refreshes the visual appeal of the building facade but also provides renewed protection against weathering and environmental stressors.

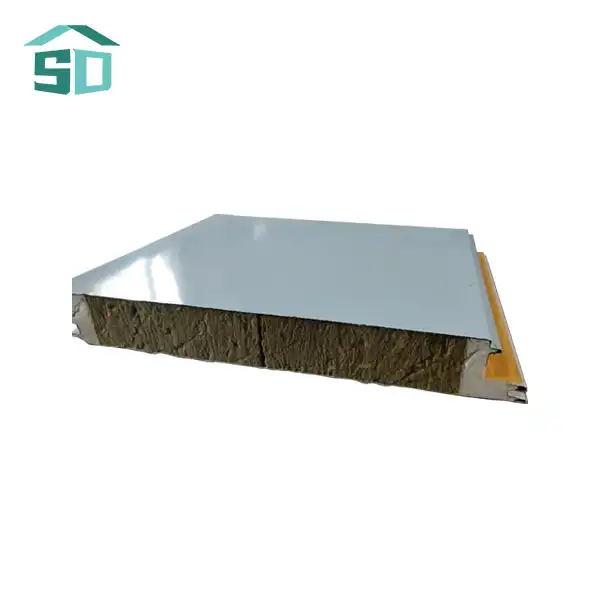

Innovative Solutions in Aluminum Siding Technology

As the demand for more durable and low-maintenance building materials grows, manufacturers are developing innovative solutions to address common issues like chalking in aluminum metal siding panels:

Advanced Paint Formulations

Unused paint innovations consolidating nano-particles and progressed polymer mixes are being created to improve UV resistance and progress the life span of painted aluminum surfaces. These inventive details point to altogether diminish chalking, a common issue caused by weathering and drawn out sun introduction. By keeping up color keenness and gleam for longer periods, these innovations offer assistance expand upkeep cycles, eventually giving both stylish and financial benefits for property proprietors and building directors.

Self-Cleaning Coatings

Rising self-cleaning coatings utilize photocatalytic properties to effectively break down natural matter, clean, and poisons when uncovered to daylight. This innovation not as it were keeps the aluminum siding boards looking clean with negligible manual intercession but moreover makes a difference decrease paint corruption and chalking over time. The result is a longer-lasting, low-maintenance outside arrangement that jam both the visual request and useful execution of aluminum cladding.

Textured Finishes

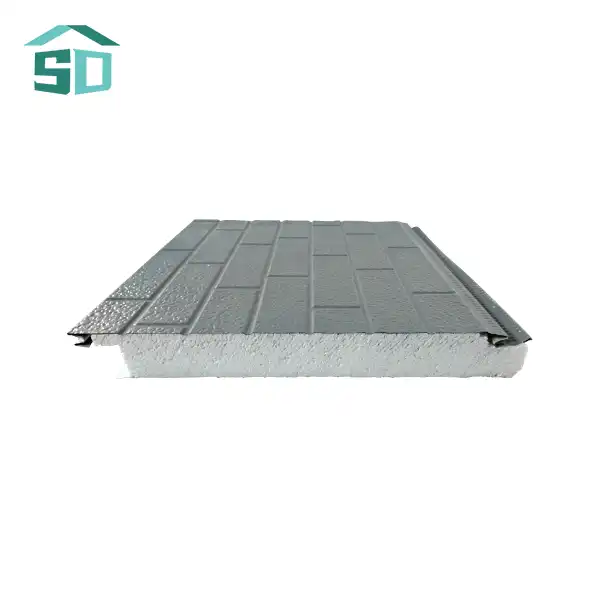

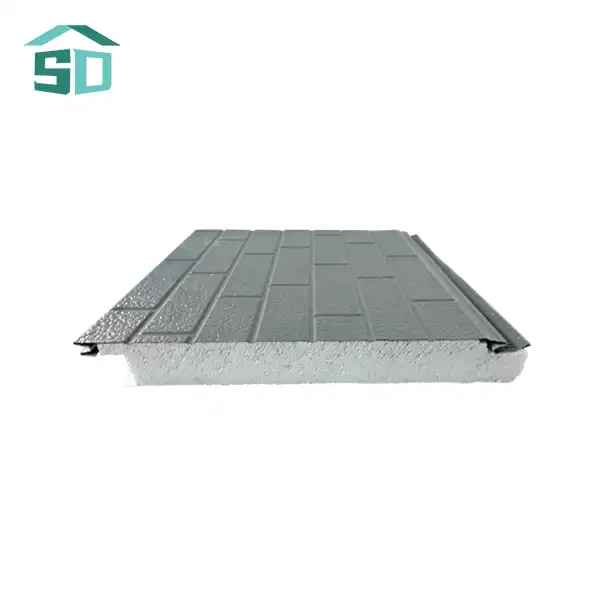

Producers are progressively investigating the utilize of finished wraps up to offer assistance cover the unmistakable impacts of chalking and keep up a more steady appearance over time. These surfaces can diffuse light, decrease surface glare, and improve the material feel of the siding. Moreover, finished surfaces can include plan flexibility and visual profundity, permitting planners and originators to make more energetic and engaging building exteriors whereas progressing down to earth toughness.

In spite of the challenges postured by chalking, aluminum metal siding boards stay a well known choice for both private and commercial applications. Their inalienable toughness, lightweight nature, and flexible plan alternatives make them exceedingly appealing to modelers and property proprietors alike. By understanding the causes of chalking and embracing proactive support and cleaning techniques, building proprietors can ensure their venture, guaranteeing aluminum siding proceeds to perform viably and keep up its stylish offer for numerous a long time.

Conclusion

For those seeking high-quality aluminum metal siding panels that offer superior resistance to chalking and other common issues, Weifang Sandong Building Materials Co., Ltd. provides innovative solutions engineered to withstand the test of time. Our advanced production lines and rigorous quality control systems ensure that every panel meets the highest standards of durability and performance. To learn more about our range of exterior cladding and facade solutions, including our state-of-the-art aluminum siding options, please contact us at info@sdqsc.com.