The Evolution of Thermal Insulation Technology

The field of thermal insulation has come a long way since its inception. Early insulation materials like asbestos and fiberglass have given way to more advanced, efficient, and environmentally friendly options. Today's thermal insulation panels are the result of years of research and development, incorporating innovative materials and manufacturing processes.

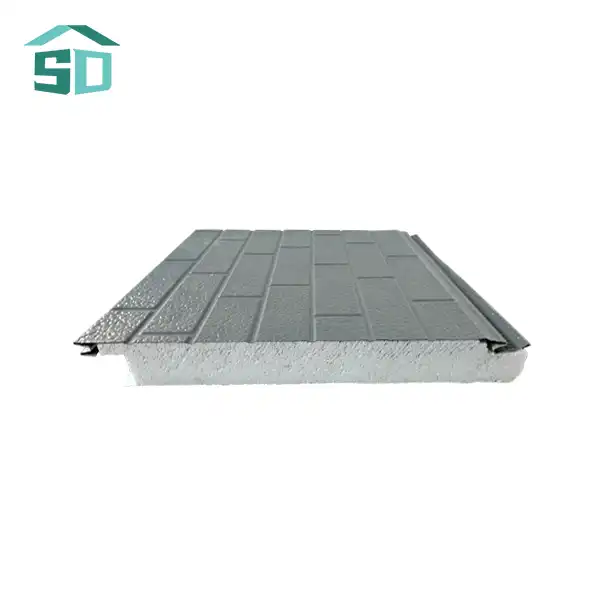

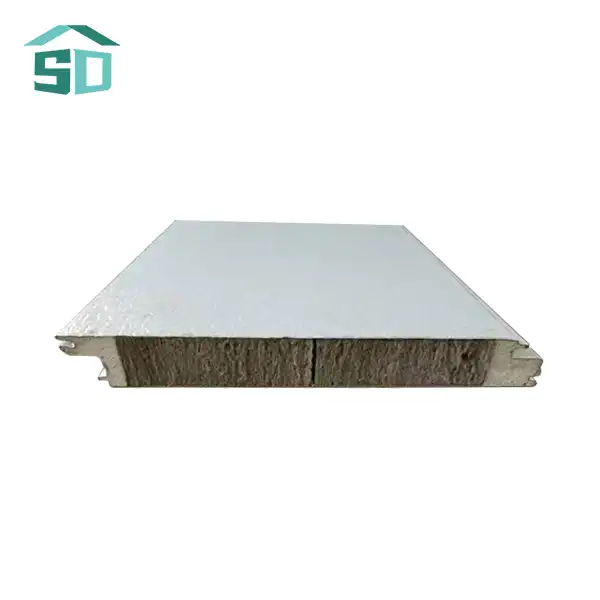

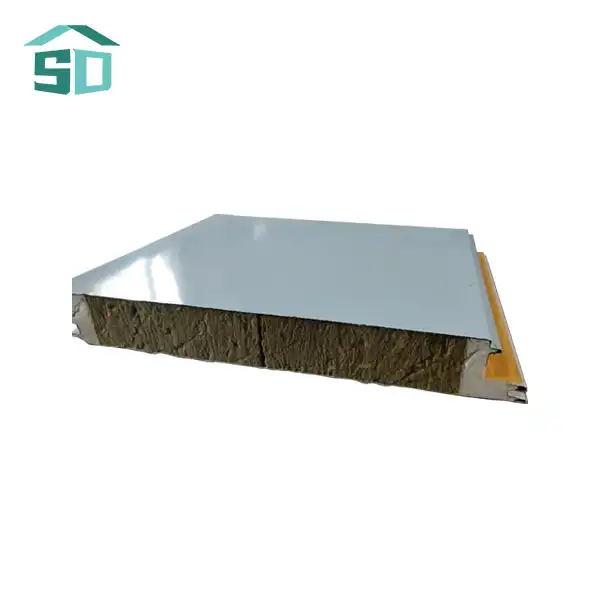

Sandong's thermal insulation panels represent the pinnacle of this evolution. These panels utilize a unique composition that maximizes insulation properties while minimizing thickness. The core material, typically polyurethane or polyisocyanurate, is sandwiched between two layers of high-quality steel or aluminum, creating a robust and efficient insulation solution.

Advancements in Material Science

The effectiveness of thermal insulation panels largely depends on the materials used in their construction. Sandong has invested heavily in material science research to develop panels that offer superior performance. The company's panels boast an impressive thermal conductivity of 0.018W/m.k, significantly lower than many competitors in the market.

This low thermal conductivity translates to excellent insulation properties, with a thermal resistance of 2.09m2k/w. Such high-performance insulation helps maintain consistent indoor temperatures, reducing the load on heating and cooling systems and subsequently lowering energy costs for building owners.

Innovative Manufacturing Techniques

Sandong employs state-of-the-art manufacturing techniques to produce their thermal insulation panels. The company's advanced production lines and rigorous quality control system ensure that each panel meets the highest standards of quality and performance.

The manufacturing process includes comprehensive inspections of steel coils, aluminum foil, and polyurethane. Each panel undergoes strict testing for thickness, paint film thickness, mechanical strength, flame retardancy, and overall appearance. This meticulous approach to quality control results in panels that consistently deliver superior performance and longevity.

Key Features of Sandong's Thermal Insulation Panels

Sandong's thermal insulation panels stand out in the market due to their impressive array of features. These panels are designed to meet the diverse needs of modern construction projects, from residential complexes to commercial buildings and industrial facilities.

Unmatched Durability and Resilience

One of the standout features of Sandong's panels is their exceptional durability. The panels are designed to withstand harsh environmental conditions, including extreme temperatures, high humidity, and corrosive atmospheres. With a compressive strength of 52.7kpa, these panels can withstand significant structural loads without compromising their insulation properties.

The panels also boast impressive wind resistance, capable of withstanding pressures up to 8.0 Kpa. This makes them ideal for use in high-rise buildings or areas prone to strong winds. Additionally, with a waterproof rate of 0.0008, these panels provide excellent protection against moisture ingress, preventing issues like mold growth and structural damage.

Fire Safety and Environmental Considerations

Safety is a paramount concern in building design, and Sandong's thermal insulation panels excel in this aspect. The panels come with a fire-protection rating of B1/B2, indicating their high resistance to fire. This non-flammable nature provides peace of mind to building occupants and helps meet stringent building safety codes.

Furthermore, Sandong is committed to environmental sustainability. The panels are manufactured using eco-friendly materials and processes, aligning with green building initiatives. Their energy-efficient properties also contribute to reducing the carbon footprint of buildings over their lifetime.

Versatility and Aesthetic Appeal

Sandong's thermal insulation panels are not just about performance; they also offer great versatility and aesthetic appeal. These panels can be customized to suit various architectural styles and design preferences, making them a favorite among architects and designers.

Customization Options

The boards come in a run of sizes to suit diverse applications. For insides utilize, boards with a thickness of 10mm and width of 450mm are accessible. Outside boards come in thicknesses of 16mm or 20mm, with a width of 383mm. The surface fabric thickness can be customized to 0.23mm, 0.25mm, or 0.27mm, permitting for fine-tuning of the panels' properties to meet particular extend necessities.

Color customization is another zone where Sandong's boards sparkle. The boards can be delivered in a wide run of colors and designs, permitting them to consistently coordinated with any plan tasteful. Whether it's a smooth, present day see or a more conventional appearance, these boards can be custom fitted to suit.

Wide Range of Applications

The versatility of Sandong's thermal insulation panels makes them suitable for a wide range of applications. They are commonly used in:

- Residential complexes

- Office buildings

- Villas and luxury homes

- Gardens and outdoor structures

- Historic building renovations

- Municipal buildings

- Security kiosks

This adaptability, combined with their superior performance, makes Sandong's panels a go-to choice for architects and builders across various sectors of the construction industry.

Easy Installation Process

Despite their advanced features, Sandong's thermal insulation panels are designed for straightforward installation. The process typically involves the following steps:

1.Preparation: Ensuring the surface is clean, dry, and free of debris

2.Layout planning: Designing the panel arrangement according to project specifications

3.Cutting: Trimming panels to required sizes using appropriate tools

4.Attachment: Securing panels using mechanical fasteners or adhesives

5.Sealing: Applying sealant around edges to prevent moisture ingress and ensure a tight fit

While professional installation is recommended for optimal results, the simplicity of this process contributes to faster construction times and reduced labor costs.

Conclusion

As we look towards 2025, Sandong's thermal insulation panels stand out as a top cost-effective solution for modern construction needs. These panels offer an optimal balance of performance, durability, safety, and aesthetic appeal, making them an excellent choice for a wide range of building projects.

Their superior insulation properties, combined with fire resistance and corrosion-free design, ensure long-term value for building owners. The customizable nature of these panels also allows for greater design flexibility, catering to diverse architectural visions.

For those seeking high-quality, energy-efficient insulation solutions that don't compromise on performance or aesthetics, Sandong's thermal insulation panels are set to be the go-to choice in 2025 and beyond. To learn more about these innovative panels and how they can benefit your next construction project, please contact us at info@sdqsc.com.