Maximizing Energy Efficiency: The Thermal Insulation Advantage

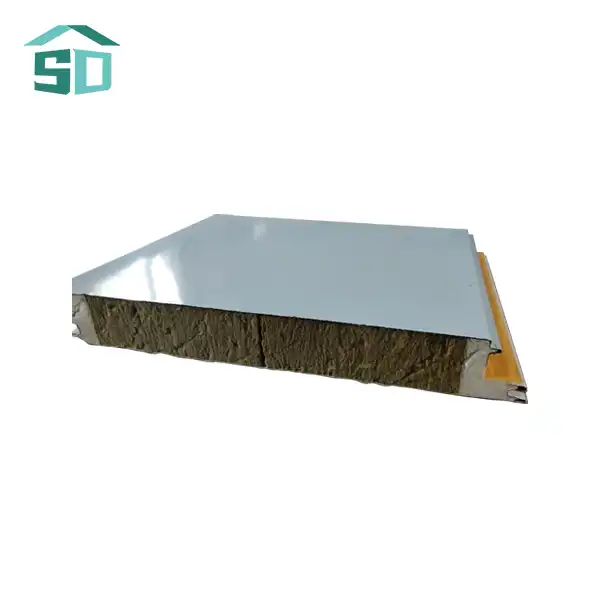

One of the most compelling reasons why polyurethane sandwich PUF panels offer substantial cost benefits is their superior thermal insulation properties. With a remarkably low thermal conductivity of 0.018W/m.k, these panels create an exceptionally effective barrier against heat transfer. This translates to significant energy savings for building owners, as the need for constant heating and cooling is greatly reduced.

Year-Round Temperature Control

The remarkable warm execution of PUF boards guarantees that insides spaces keep up perfect temperatures all through the year. Amid burning summers, the boards avoid warm from entering the building, decreasing the stack on discuss conditioning frameworks. Alternately, in cold winters, they trap warmth interior, minimizing warm misfortune and diminishing the burden on warming frameworks. This year-round temperature control not as it were upgrades consolation but too leads to significant decreases in vitality utilization and related costs.

Long-Term Energy Savings

The energy efficiency of polyurethane sandwich PUF panels translates into tangible, long-term cost savings. Building owners can expect to see a noticeable decrease in their energy bills from the moment these panels are installed. Over time, these savings accumulate, often offsetting the initial investment in the panels themselves. For large-scale commercial or industrial buildings, where energy costs can be a significant portion of operating expenses, the impact of PUF panels on the bottom line can be substantial.

Durability and Longevity: Reducing Maintenance and Replacement Costs

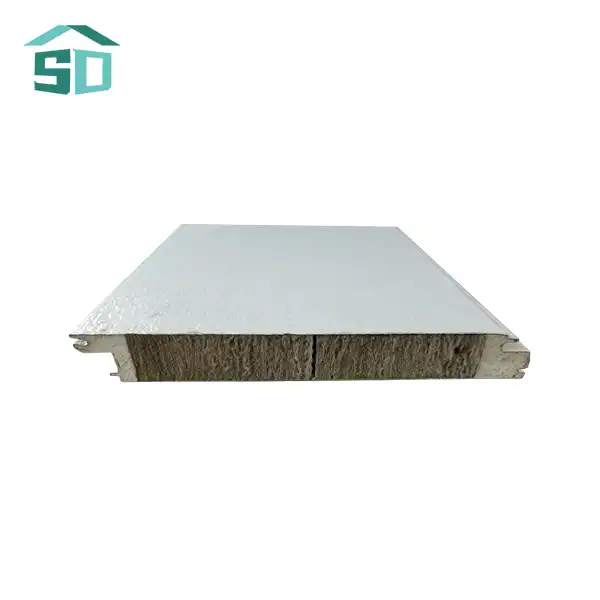

Another key factor contributing to the cost benefits of polyurethane sandwich PUF panels is their exceptional durability and longevity. These panels are engineered to withstand a wide range of environmental challenges, ensuring they maintain their performance and appearance for years to come.

Weather Resistance

Polyurethane sandwich PUF panels boast impressive weather-resistant properties. With a waterproof rate of 0.0008, they provide excellent protection against moisture infiltration, preventing water damage and mold growth. Additionally, their ability to withstand wind pressures of up to 8.0 Kpa ensures they remain stable and intact even in extreme weather conditions. This resilience translates to reduced maintenance costs and fewer repairs over the lifespan of the building.

Fire and Corrosion Resistance

The panels' fire-protection rating of B1/B2 enhances building safety and can potentially lower insurance premiums. Their corrosion-resistant properties further contribute to their longevity, particularly in coastal or industrial areas where corrosive elements are prevalent. By resisting degradation from environmental factors, polyurethane sandwich PUF panels maintain their structural integrity and insulative properties for extended periods, reducing the frequency and cost of replacements.

Minimal Maintenance Requirements

The strong development and high-quality materials utilized in PUF boards result in negligible support prerequisites. Not at all like conventional building materials that may require visit portray, fixing, or repairs, these boards hold their appearance and usefulness with small mediation. This low-maintenance characteristic not as it were spares cash on upkeep but too decreases the disturbance to building tenants that frequently goes with support exercises.

Versatility and Customization: Optimizing Construction Costs

The versatility and customization options offered by polyurethane sandwich PUF panels provide yet another avenue for cost savings in construction projects. Their adaptability to various design requirements and building types allows for optimized construction processes and reduced material waste.

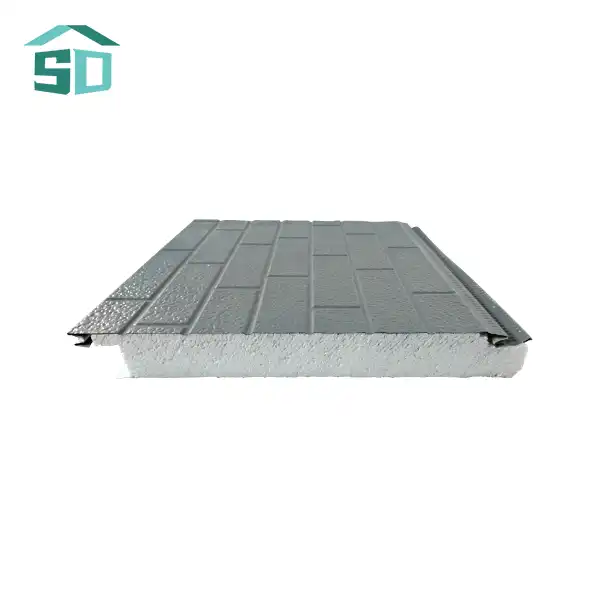

Tailored Dimensions and Finishes

Polyurethane sandwich PUF panels can be customized to precise dimensions, thicknesses, and finishes to meet specific project needs. This customization capability minimizes on-site modifications, reducing labor costs and material waste. The ability to tailor panel sizes (with exterior widths of 383mm and interior widths of 450mm) and thicknesses (10mm for interiors, 16mm/20mm for exteriors) ensures an efficient use of materials and streamlined installation process.

Lightweight Construction

The lightweight nature of PUF panels, combined with their strength (compressive strength of 52.7kpa), makes them ideal for rapid installation. This characteristic not only accelerates construction timelines but also reduces labor costs associated with handling and installation. Furthermore, the reduced weight can lead to savings in structural support requirements, potentially allowing for more economical building designs.

Aesthetic Flexibility

The design flexibility of polyurethane sandwich PUF panels allows architects and builders to achieve desired aesthetic outcomes without compromising on performance. The panels can be produced in a variety of colors and patterns, eliminating the need for additional cladding or finishing materials. This integration of form and function can lead to significant cost savings in both materials and labor during the construction phase.

Conclusion

Polyurethane sandwich PUF panels offer a compelling combination of energy efficiency, durability, and versatility that translates into substantial cost benefits for construction projects. From reducing energy consumption and maintenance expenses to optimizing construction processes, these innovative panels provide a cost-effective solution for modern building needs. As the construction industry continues to evolve, the adoption of PUF panels represents a smart investment in both immediate and long-term cost savings.

For more information about our high-quality polyurethane sandwich PUF panels and how they can benefit your next construction project, please don't hesitate to contact us at info@sdqsc.com. Our team of experts at Weifang Sandong Building Materials Co., Ltd. is ready to assist you in finding the perfect exterior cladding and facade solutions for your needs.