Unveiling the Power of PU Insulation Panels

What Are PU Insulation Panels?

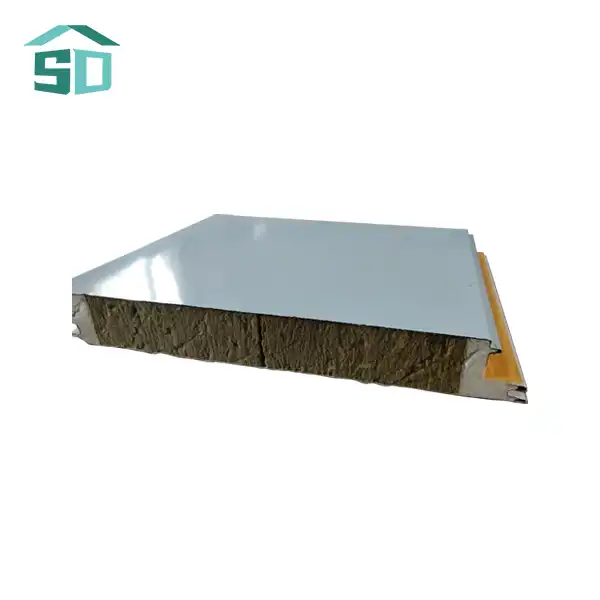

PU insulation panels, short for polyurethane insulation panels, are high-performance building materials designed to provide superior thermal insulation. These panels consist of a rigid polyurethane foam core sandwiched between two layers of facing material, typically metal or other durable substrates, which enhance strength and durability. The unique composition of PU insulation panels makes them an ideal choice for both interior and exterior applications, offering a blend of lightweight construction, high insulation efficiency, and design flexibility that meets modern architectural demands.

The Science Behind PU Insulation

The extraordinary protection properties of PU boards stem from their progressed closed-cell structure. This structure viably traps incalculable modest discuss bubbles inside the froth framework, making a exceedingly proficient boundary against warm exchange and minimizing warm bridging. With a warm conductivity of fair 0.018 W/m·K, PU cover boards outflank numerous conventional cover materials like mineral fleece or EPS. This moo warm conductivity interprets to a higher R-value, guaranteeing ideal warm execution over differing climates and contributing to in general building vitality productivity.

Versatility in Application

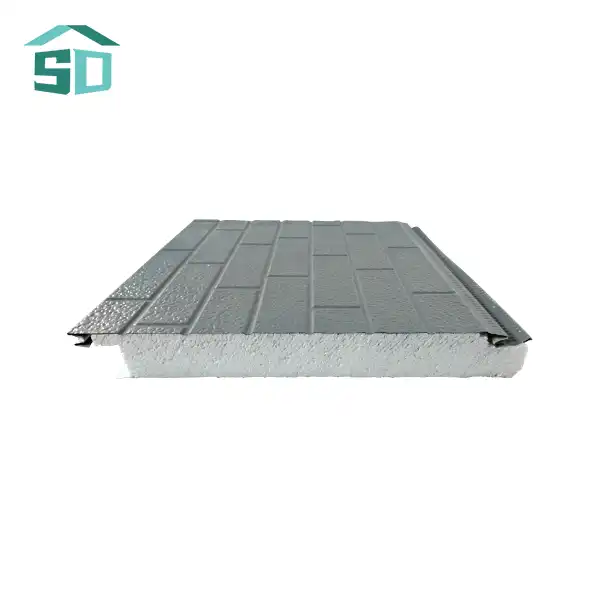

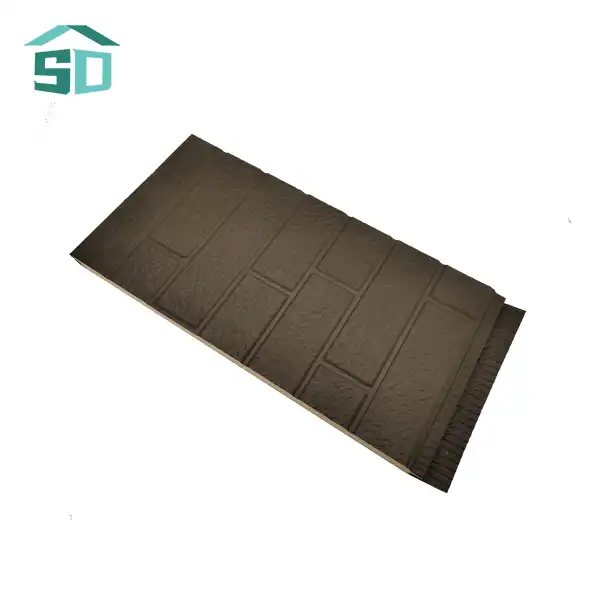

One of the key advantages of PU insulation panels is their impressive adaptability to a wide range of construction needs and design preferences. These panels are suitable for both interior and exterior wall applications, making them ideal for residential, commercial, and industrial projects alike. With thickness options ranging from 10 mm for interior use to 16 mm or 20 mm for exterior installations, they can be tailored to meet specific thermal and structural requirements. Additionally, panel widths—383 mm for exterior facades and 450 mm for interior partitions—provide flexibility in layout and installation, supporting creative architectural solutions.

Enhancing Comfort and Efficiency with PU Insulation Panels

Superior Thermal Performance

The essential work of PU cover boards is to keep up a comfortable indoor environment by minimizing warm exchange. With a warm resistance of 2.09m²K/W, these boards successfully keep add warm in winter and cool in summer. This steady temperature control not as it were upgrades consolation but moreover diminishes the strain on warming and cooling frameworks, driving to noteworthy vitality reserve funds.

Moisture Resistance and Indoor Air Quality

PU insulation panels boast an impressive waterproof rate of 0.0008, making them highly resistant to moisture infiltration. This characteristic is crucial in preventing mold and mildew growth, which can adversely affect indoor air quality. By keeping moisture at bay, PU panels contribute to a healthier living environment and protect the structural integrity of the building.

Noise Reduction Properties

In addition to thermal insulation, PU panels offer excellent sound insulation properties. This feature is particularly beneficial in urban settings or multi-unit buildings where noise reduction is a priority. The panels' ability to dampen sound transmission creates quieter, more peaceful indoor spaces, enhancing overall comfort and well-being.

Installation and Long-Term Benefits of PU Insulation Panels

Effortless Installation Process

Installing PU insulation panels is a straightforward process that requires minimal specialized tools or labor. The lightweight nature of these panels, coupled with their easy-to-handle dimensions, makes them a cost-effective solution for builders and contractors. The installation typically involves four key steps:

1.Preparation: Ensuring the surface is clean and dry

2.Cutting: Measuring and cutting panels to size if necessary

3.Fixing: Using appropriate fasteners and adhesives

4.Finishing: Sealing joints with compatible sealants

Durability and Longevity

PU insulation panels are built to last. With a compressive strength of 52.7kPa and high resistance to weathering, corrosion, and UV damage, these panels maintain their performance over extended periods. This durability translates to lower maintenance costs and a longer lifespan for the building envelope, ensuring sustained performance, enhanced structural integrity, and long-term value for property owners.

Fire Safety and Compliance

Safety is paramount in building design, and PU insulation panels address this concern with their fire-resistant properties. Available in fire-protection ratings of B1 and B2, these panels meet stringent safety standards. This feature provides peace of mind for occupants and helps buildings comply with local fire safety regulations.

Customization Options

PU insulation panels offer extensive customization possibilities to suit various architectural styles and project requirements. With options for different surface materials (0.23mm, 0.25mm, or 0.27mm thickness) and the ability to tailor panel dimensions, designers can achieve both functional and aesthetic goals. This flexibility makes PU panels an attractive choice for a wide range of projects, from residential complexes to commercial buildings.

Environmental Considerations

As the development industry progressively centers on maintainability, PU separator boards stand out as an eco-friendly choice. Their energy-saving properties contribute to decreased carbon emanations over the building's lifetime. Furthermore, numerous producers presently create these boards utilizing naturally inviting materials and forms, adjusting with green building activities.

Conclusion

PU insulation panels represent a cutting-edge solution for maximizing comfort, energy efficiency, and building performance. Their superior thermal insulation properties, coupled with moisture resistance, sound dampening, and fire safety features, make them an invaluable asset in modern construction. Whether you're undertaking a new build or renovating an existing structure, integrating PU insulation panels can significantly enhance the overall quality and sustainability of your project.

For those looking to elevate their building's performance and create more comfortable, energy-efficient spaces, PU insulation panels offer a compelling solution. To learn more about how these innovative panels can benefit your specific project, or to explore our range of exterior cladding and facade solutions, we invite you to contact us at info@sdqsc.com. Our team of experts is ready to assist you in making informed decisions that will enhance your building's comfort, efficiency, and longevity.