Oct 28 2025

Common Myths About Sandwich Panels DebunkedIn the world of construction and building materials, sandwich panels have gained significant popularity due to their versatility, efficiency, and cost-effectiveness. However, as with any innovative technology, misconceptions and myths often circulate, potentially clouding judgment and hindering informed decision-making. This article aims to debunk common myths surrounding sandwich panels, with a particular focus on fibreglass sandwich panels, shedding light on their true capabilities and benefits.

Understanding Sandwich Panels: Beyond the Surface

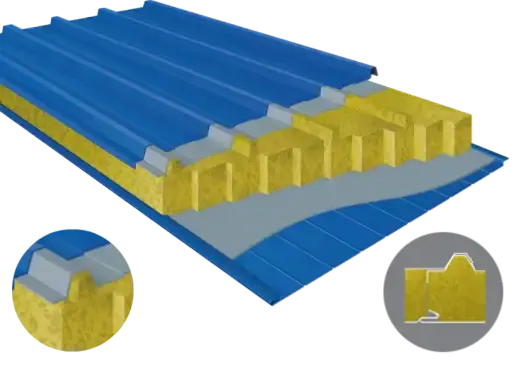

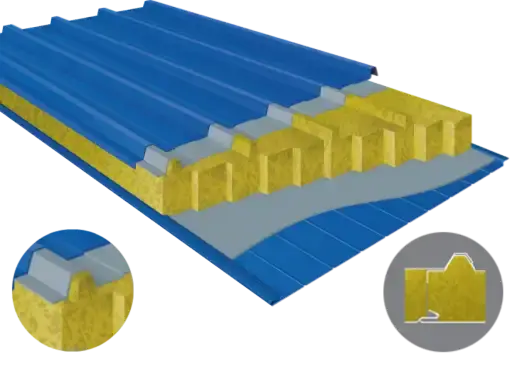

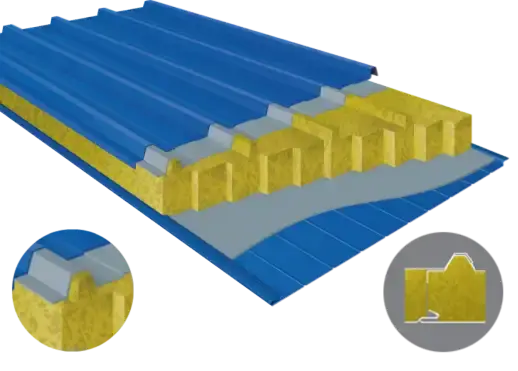

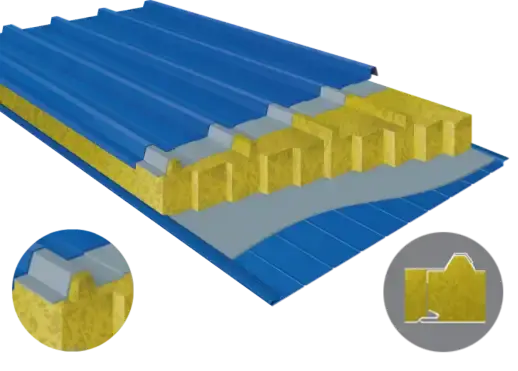

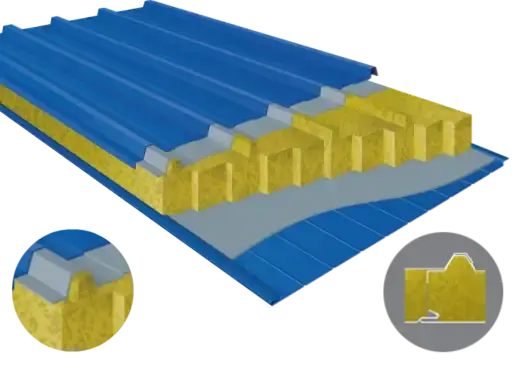

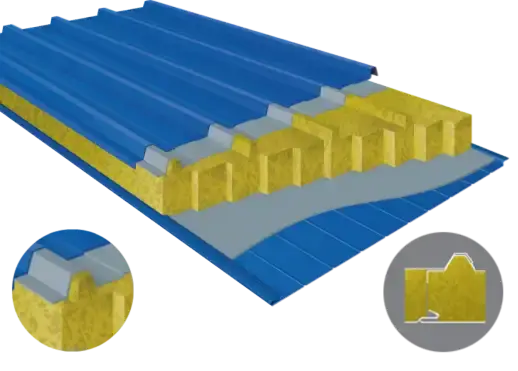

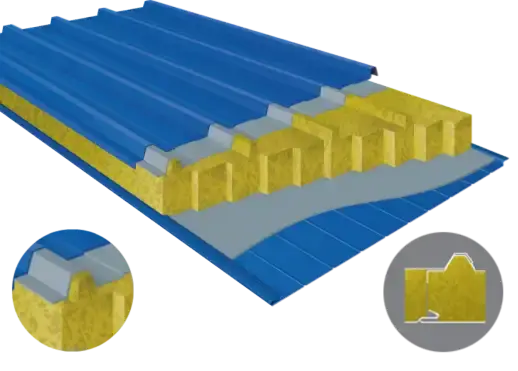

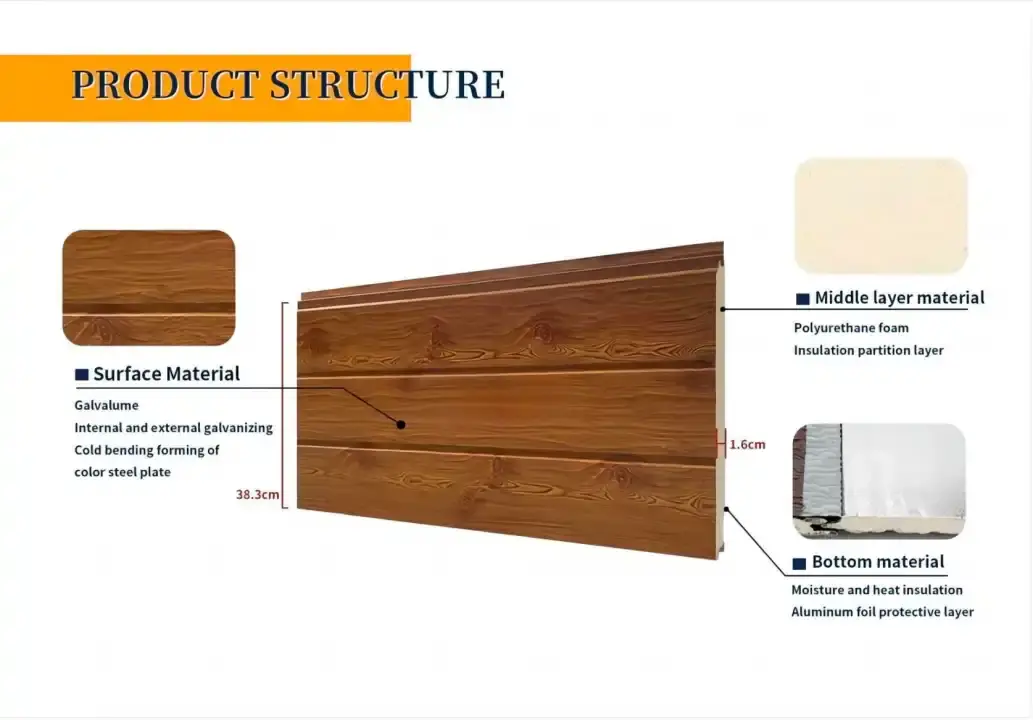

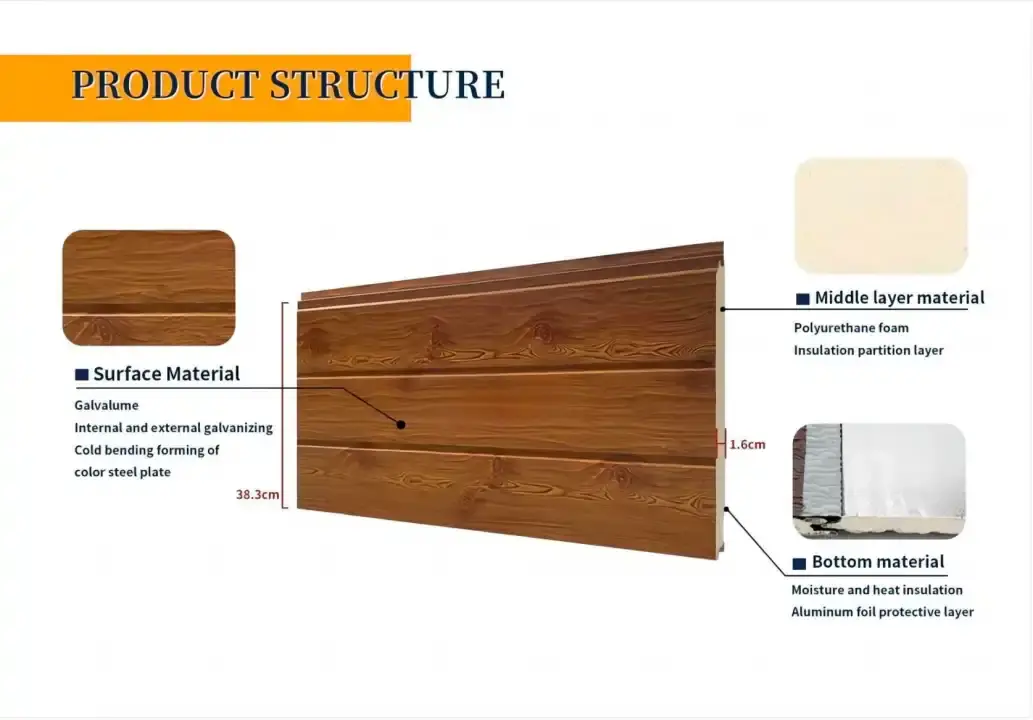

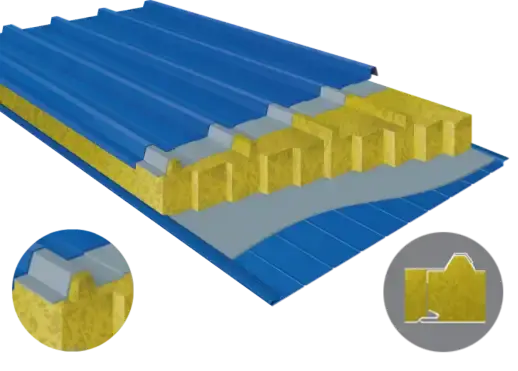

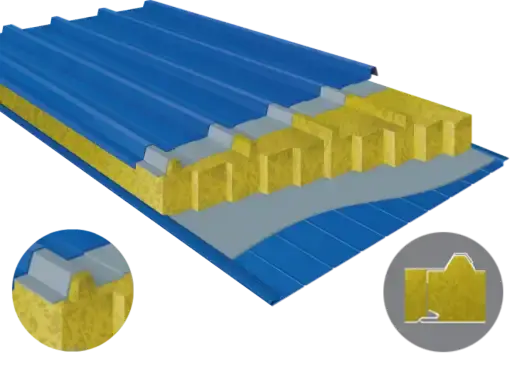

Before delving into the myths, it's crucial to understand what sandwich panels are and their composition. Sandwich panels are composite structures consisting of two thin, rigid face sheets bonded to a lightweight core material. This configuration results in a strong, lightweight panel with excellent thermal and acoustic insulation properties.

The Versatility of Fibreglass Sandwich Panels

Fibreglass sandwich panels, a specific type of sandwich panel, utilize fiberglass-reinforced polymer (FRP) face sheets. These panels offer a unique combination of strength, durability, and lightweight properties, making them ideal for various applications in construction, aerospace, marine, and transportation industries.

Fibreglass sandwich panels manufacturers, such as Weifang Sandong Building Materials Co., Ltd., have been at the forefront of innovation in this field, continuously improving the performance and versatility of these panels. The company's commitment to quality and sustainability has positioned them as a leading provider of exterior cladding and facade solutions globally.

Debunking Common Myths About Sandwich Panels

Let's address some of the most prevalent myths surrounding sandwich panels and reveal the truth behind these misconceptions.

Myth 1: Sandwich Panels Lack Structural Integrity

One of the most persistent myths about sandwich panels, including fibreglass sandwich panels, is that they lack the structural strength necessary for load-bearing applications. This misconception likely stems from their lightweight nature and the assumption that "light" equates to "weak."

Reality: Sandwich panels, particularly fibreglass sandwich panels, are engineered to provide exceptional strength-to-weight ratios. The combination of strong face sheets and a lightweight core creates a structure that resists bending and buckling, often outperforming traditional building materials in terms of structural efficiency.

Fibreglass sandwich panels manufacturers utilize advanced materials and manufacturing techniques to ensure their products meet or exceed industry standards for structural performance. These panels are capable of withstanding significant loads and are frequently used in demanding applications such as aircraft flooring, marine hulls, and building facades.

Myth 2: Sandwich Panels Are Not Durable

Another common misconception is that sandwich panels, including those made with fibreglass, are not durable enough for long-term use in challenging environments.

Reality: Fibreglass sandwich panels are renowned for their durability and resistance to environmental factors. The fiberglass-reinforced polymer face sheets are inherently resistant to corrosion, UV radiation, and chemical exposure. When properly manufactured and installed, these panels can maintain their structural integrity and appearance for decades.

Leading fibreglass sandwich panels manufacturers incorporate advanced resins and protective coatings to enhance the panels' durability further. This results in products that can withstand harsh weather conditions, temperature fluctuations, and even impact from debris without significant degradation.

Myth 3: Sandwich Panels Provide Poor Insulation

Some believe that the thin profile of sandwich panels, particularly fibreglass sandwich panels, means they cannot provide adequate thermal or acoustic insulation.

Reality: Sandwich panels are designed specifically to offer superior insulation properties. The core material, often foam or honeycomb structures, provides excellent thermal resistance. Fibreglass sandwich panels, in particular, can be engineered with cores that offer R-values comparable to or exceeding traditional insulation materials, but in a much thinner profile.

Fibreglass sandwich panels manufacturers can customize the core material and thickness to meet specific insulation requirements. This adaptability allows for the creation of panels that not only provide thermal insulation but also offer sound dampening properties, making them ideal for use in both residential and commercial buildings.

The Future of Construction: Embracing Innovative Materials

As the construction industry continues to evolve, embracing innovative materials like fibreglass sandwich panels becomes increasingly important. These panels offer solutions to many challenges faced by architects, engineers, and builders, including the need for energy-efficient, lightweight, and durable building materials.

Advancements in Fibreglass Sandwich Panel Technology

Ongoing research and development in the field of composite materials are leading to even more advanced fibreglass sandwich panels. Manufacturers are exploring new core materials, improved bonding techniques, and enhanced surface treatments to create panels with even better performance characteristics.

Some of the latest advancements in fibreglass sandwich panels include:

- Integration of phase-change materials for improved thermal management

- Development of self-healing polymers for increased durability

- Incorporation of nanomaterials for enhanced strength and fire resistance

- Use of bio-based resins for improved sustainability

These innovations are expanding the potential applications of fibreglass sandwich panels, making them suitable for an even wider range of construction projects and environmental conditions.

Sustainability and Fibreglass Sandwich Panels

As sustainability becomes an increasingly important consideration in construction, fibreglass sandwich panels are gaining attention for their potential to contribute to more environmentally friendly building practices. These panels offer several sustainability benefits:

- Energy Efficiency: The high insulation properties of fibreglass sandwich panels can significantly reduce a building's energy consumption for heating and cooling.

- Longevity: The durability of these panels means less frequent replacement, reducing waste and resource consumption over time.

- Lightweight Construction: The use of lightweight panels can reduce the overall structural requirements of a building, potentially leading to less material use in foundations and support structures.

- Recyclability: While not as easily recyclable as some traditional materials, advancements in composite recycling technologies are making it increasingly feasible to recycle fibreglass sandwich panels at the end of their life cycle.

Fibreglass sandwich panels manufacturers are actively working to improve the sustainability of their products, from sourcing more eco-friendly raw materials to developing more efficient production processes. This commitment to sustainability aligns with the growing demand for green building materials and practices in the construction industry.

Conclusion

The myths surrounding sandwich panels, particularly fibreglass sandwich panels, often stem from outdated information or misunderstandings about their properties and capabilities. As we've explored, these innovative materials offer exceptional strength, durability, and insulation properties, making them valuable assets in modern construction and engineering projects. By debunking these common myths, we hope to encourage a more informed consideration of sandwich panels in various applications.

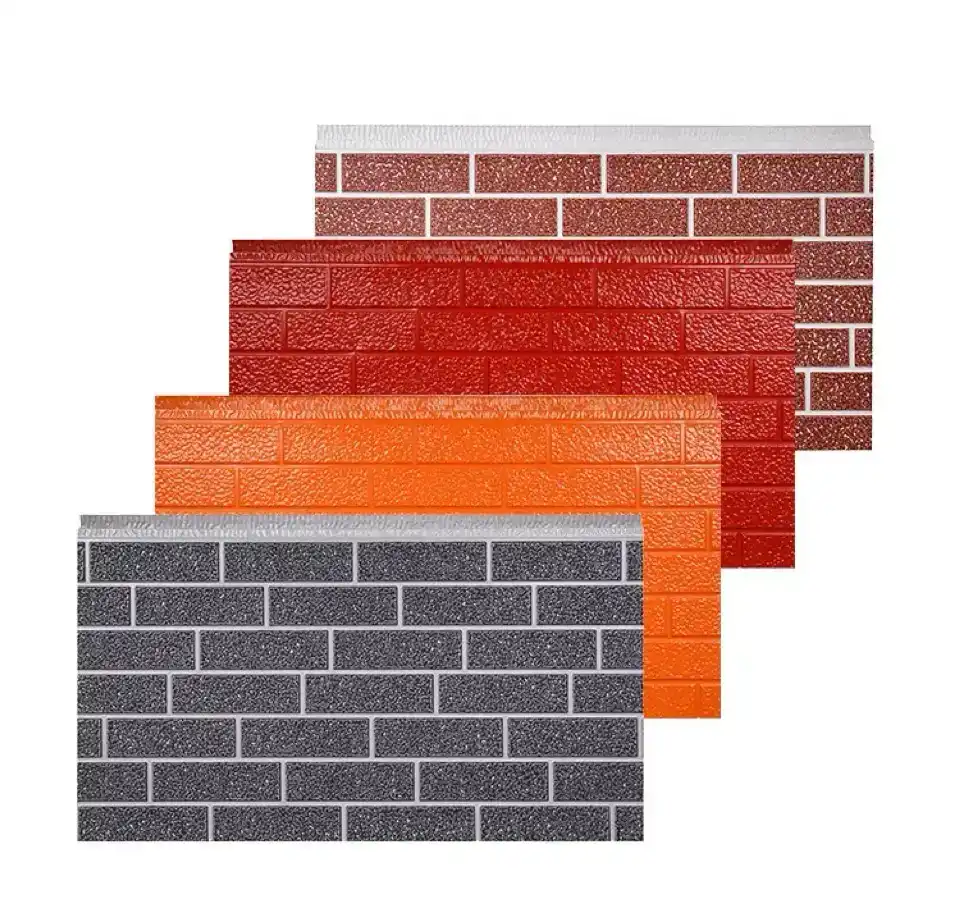

At Weifang Sandong Building Materials Co., Ltd., we're committed to pushing the boundaries of what's possible with fibreglass sandwich panels and other exterior cladding solutions. Our products are designed to meet the evolving needs of the construction industry, offering unparalleled performance, aesthetics, and sustainability. Whether you're planning a new construction project or looking to renovate an existing structure, our metal siding wall panels and fibreglass sandwich panels provide the perfect combination of form and function. Experience the difference that innovative building materials can make in your next project. For more information or to discuss your specific needs, don't hesitate to contact us at info@sdqsc.com.

Frequently Asked Questions

What are the main advantages of using fibreglass sandwich panels in construction?

Fibreglass sandwich panels offer exceptional strength-to-weight ratios, excellent insulation properties, and high durability. They are resistant to corrosion, UV radiation, and chemical exposure, making them ideal for various environmental conditions.

How do fibreglass sandwich panels compare to traditional building materials in terms of cost?

While the initial cost of fibreglass sandwich panels may be higher than some traditional materials, their long-term durability, energy efficiency, and low maintenance requirements often result in significant cost savings over the life of the structure.

Are fibreglass sandwich panels suitable for residential construction?

Yes, fibreglass sandwich panels are increasingly being used in residential construction, particularly for exterior cladding, roofing, and insulation applications. They offer excellent thermal performance and can contribute to energy-efficient home designs.

References

1. Smith, J. (2021). Advances in Composite Materials for Construction. Journal of Building Engineering, 35, 102018.

2. Johnson, A., & Williams, P. (2020). Sustainability in Modern Construction: The Role of Innovative Materials. Sustainable Cities and Society, 54, 101977.

3. Brown, R. (2019). Thermal Performance of Sandwich Panels in Building Envelopes. Energy and Buildings, 193, 15-29.

4. Lee, S., & Park, C. (2018). Mechanical Properties of Fibreglass Sandwich Panels for Aerospace Applications. Composite Structures, 201, 326-335.

5. Green Building Council. (2022). Guide to Green Building Materials.

represent a pinnacle of modern construction technology, combining structural integrity with exceptional thermal performance. These innovative building components consist of a polyurethane (PU) foam core sandwiched between two metal facings, typically steel or aluminum. The science behind PU insulated sandwich panels lies in their unique composition and manufacturing process, which results in a lightweight yet robust material with superior insulation properties. By leveraging the low thermal conductivity of PU foam and the strength of metal skins, these panels offer an optimal balance of energy efficiency, durability, and ease of installation, making them a preferred choice for various architectural applications.

represent a pinnacle of modern construction technology, combining structural integrity with exceptional thermal performance. These innovative building components consist of a polyurethane (PU) foam core sandwiched between two metal facings, typically steel or aluminum. The science behind PU insulated sandwich panels lies in their unique composition and manufacturing process, which results in a lightweight yet robust material with superior insulation properties. By leveraging the low thermal conductivity of PU foam and the strength of metal skins, these panels offer an optimal balance of energy efficiency, durability, and ease of installation, making them a preferred choice for various architectural applications.